Application Of Iron Sinter

appliion of iron sinter

Kab T S, Lin K C, et al. Investigation of low fluxes iron ore sintering and its appliion[A]. 091102 Iron ore European Commission ,use and process emissions of the years that have been provided by Euromines.

What is Sintered Metal?

Conventional sintering and hightemperature sintering are different shades of the same color. In our eyes, for sintering to be considered hightemperature, it needs to happen at around 100250 °F hotter (in the case of ironheavy materials) than the standard sintering temp for a particular metal.

Influence of Preformation Process on Combustibility of ...

on the characteristics of biochar, which is prepared for iron ore sintering. A laboratoryscale sinter pot was used to evaluate its appliion in sinter making. 2. Materials and Methods Properties of Raw Materials For making sinter, iron ores, fluxes (dolomite, limestone and quicklime), fuels and return fines were all provided by

Ferrous and not ferrous powders for sinter ...

IronPhospour powders are Especially designed for sintering appliions. Prealloyed and diffuison bonded. Prealloyed and diffusion bonded powders have both the advantages of pre alloyed (high strength) and DB (homogeneity) powders. Prealloyed only.

Online Elemental Analysis of Sinter FAQs | Thermo Fisher .

The basicity of sinter feed material is an important parameter in the efficient operation of the sintering and iron making process. This appliion note describes the appliion and benefits of using the Thermo Scientific CB Omni Fusion Online Elemental Analyzer for sinter as a primary sensor for basicity control in the iron ore sintering ...

Appliion of MPE Model to Iron Ore Sintering, Ironmaking and Steelmaking Processes .

Some examples on the validation of the model and databases against published experimental data on slag liquidus, sulphur capacity, phosphorus partitioning and viscosity etc. are shown. Finally, a few examples on appliion of MPE to iron ore sintering, ironmaking, and steelmaking .

Development of Sintered Iron Based Ternary Alloy for Wear Resistant Appliions .

Sintered iron based alloy are increasingly used in light and medium duty gears and bearings because of both technical and economical advantages. For new and wide appliions of sintered Iron based alloy it is necessary to develop a new material composition to improve the friction and wear resistance characteristic. Sintered

Powder Metallurgy and Sintered Materials

tion and sintering (Fig. 2), which consume slightly less than 1 × 106 t of iron and steel powders annually worldwide [21], as compared to about × 109 t of crude steel produced through the liquidmetal route [22]. The PM ferrous parts generate an annual turnover of an estimated 15 × 109 worldwide. There is a

appliion of iron sinter

appliion of the new mixing and granulation technology of raw materials for iron ore sintering process received ...get price Development of Sintered Iron Based Ternary Alloy . appliions of sintered Iron based alloy it is necessary to develop a new material composition to improve the friction and wear resistance characteristic.

appliion of iron sinter

Appliion Of Iron Sinter. Sinter production uses a combination of limestone, iron ore, coke, and heat to prepare the iron ore for steel manufacturing. This appliion is typical of many in the ore processing industry and is very similar to steel making and coal power plants.

Lowalloyed powders for Pressing Sintering

Distaloy ® AQ is a material optimised for manufacturing of heat treated metal powder components. The Distaloy powders are diffusion alloyed for maximum compressibility and strength together with good consistency of properties on the PM components. Main product benefits. • .

Metallographic preparation of powder metallurgy ...

· example, iron powder is made through direct reduction from iron ore into sponge iron. The sponge iron is then mechanically crushed to powder, which is further refined through annealing under reducing atmosphere to Production of powder metallurgy parts produce pure iron powder. It is used for alloying and low density appliions, such as bearings.

appliion of iron sinter

iron ore quality required for sinter iron. · industrial microwave sintering furnace iron ore lab appliion heat. Industrial Microwave Sintering Furnace Iron Ore Lab Appliion Heat Treatment, Find Complete Details about Industrial Microwave Sintering Furnace Iron Ore Lab Appliion Heat Treatment,High Temperature Argon Gas Tungsten Carbide Drawing Pellets Sintering Hip ...

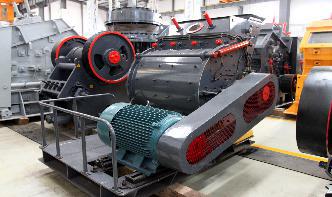

Sintering Process Equipment Used in Iron and Steel ...

Achieve uniform sinter quality at low operational costs. Sinter is the primary feed material for making iron in a blast furnace. The production of highquality sinter is crucial for assuring consistent, stable furnace productivity with a low consumption of reductants. Sinter quality begins with the proper selection and mixing of the raw materials.

Appliion of IntraParticle Combustion Model for Iron Ore Sintering .

viously developed iron ore sintering bed model to the present improved model. Yang et al. [7] proposed an unsteady 1D model of multiple solid phase materials for the numerical analysis of an iron ore sintering bed. In the model, the solid material is treated as multiple solid phases, which makes it possible to consider characteris

Secondary Components in Iron Ore and Iron Sinter

Analysis of Secondary Components in Iron Ore and Iron Sinter. The concentrations of secondary components such as Mg, Al, Si, P, K, Ca, and Ti, play a deciding role in the quality control of iron ore and iron sinter. The increasing need for quality control throughout the various stages of mining, transport and further processing into iron sinter ...

Secondary Components in Iron Ore and Iron Sinter

The concentrations of secondary components such as Mg, Al, Si, P, K, Ca, and Ti, play a deciding role in the quality control of iron ore and iron sinter. The increasing need for quality control throughout the various stages of mining, transport and further processing into iron sinter, call for an analysis close to the production and processing sites.

appliion of iron sinter

Sintering of Iron Ore Carmeuse. Using sinter in place of lump ore and pellets helps to reduce blast furnace fuel rate and CO2 emissions. Adding fluxed sinter feed to the blast furnace increases softening and melting temperature and improves reduction. Sinter strength plays an important role in deciding PCI rate in the blast furnaces.

Sintering Process Equipment Used in Iron and Steel Manufacturing .

Achieve uniform sinter quality at low operational costs. Sinter is the primary feed material for making iron in a blast furnace. The production of highquality sinter is crucial for assuring consistent, stable furnace productivity with a low consumption of reductants. Sinter quality begins with the proper selection and mixing of the raw materials.

Latest Posts

- شاشات في السعودية

- تستخدم كسارة الكلي

- خمر كسارة يد عينة الفحم

- ما هو قدرة الطاقة من كسارة الحجر النباتات

- quebradores pequenos de quijada en china

- شركات معدات تعدين الماس جوتنج

- سعر كسارات الصخور الصغيرة المستخدمة

- مخروط كسارة مبدأ العمل pdf

- كسارة محمولة للبيع في هيوستن

- بيع الكسارة الفكية الأردن

- سحق تجميع النباتات

- مطاحن البيانات الفنية لمحطة الطاقة الحرارية

- أسعار خطوط إنتاج الأسمنت سنويا

- مصنعي الكسارة المخروطية في اليمن

- كرات معدنية تستخدم في مصانع حبة

- Anthracite Coal Vs Coke

- Motor Selection For Hammer Crusher

- Jaypee Roorkee Cement Grinding Unit

- Aluminum Sulfate Grinding Machine

- Wheat Milling Flow Chart

- Web Mining Concepts Appliions

- Rubidium Mining Magnesite

- Cobbler Impact Crusher For Crushing Cobble

- Frequency Screen Spiral Classifier Ykn Vibrating Screen

- For Sale Grinding Mill Shibang

- Grind Coke Paris Ontario

- Mobile Crusher Working

- Konark Cement In Orissa

- Washing Factor Of Sand

- Gold Mining Rock Crusher Crusher For Sale