Ball Mill Principle Ball Mill Working Principle

ball mill operating principle

Ball mill working principle to be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a

Size Reduction: Introduction, Advantages, disadvantages ...

· Which of the following mill works on the principle of both attrition and impact? A. Ball mill B. Hammer mill C. Cutter mill D. Pin mill. 9. Which of the following statement is NOT true? A. Penetration becomes slow when particles are large B. Wet grinding is used for production of tablets C. Colloid mill is not used for dry milling D. Impact is done in 2 ways. 10. Which type of particles is ...

ball mill principle construction working

Ball Mill for sale Ball Mill Working Principle ball mills. Ball mill is an efficient tool for fine powder grinding. The Ball Mill is used to grind many kinds of mine and other materials or to select the mine. Ball mill is widely used in building . Chat Now ; cement mill working principlePopular Eduion. What is the working principle of ball mill Quora Niu Suge 2 years working at mining ...

Ball Mill

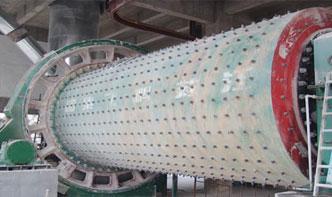

The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in ...

Rod Mills

· Rod Mill Working Principle Components. A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of the machine, which is most commonly between eight and sixteen feet in length. The diameter of these rods will range from, when new, between two and four inches. The rods are free inside the mill. When the mill is turned, .

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Ball Mill Working Principles

Ball Mill Working Principles. Ball mill critical speed working principle ball mill working principle to be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia and centrifugal force the effects of friction making it attached to the cylinder ...

Ball Mill Working Principle

Ball Mill Working Principle Ball Mill Working Principle. Material from the feed device into the mill warehouse, there are ladder liner or corrugated liner in the warehouse, built with different specifiions grinding balls, to make the positions of the materials and grinding ball mill evenly distributed, to avoid starting difficulties due emphasis cause ...

working principles of ball mill

working principles of ball mill. If you want to learn about our products, please call or write mail consultation. Several types of ball mills exist they differ to an extent in their operating principle they also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several liters for horizontal rolling ...

cement ball mill principles

Cement ball mill principle of operation. ball mill working principle and main mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out ...

Ball Mill Principle, Construction, Working, Merits, Demerits

Ball Mill Principle, Construction, Working, Merits, Demerits, Appliions, Sunil Bakliwal D. D. Vispute College of Pharmacy, Pharmaceutical engineering

AG Autogenous Grinding

· The closed circuit test mill was installed in an operating plant in parallel with existing conventional rod millball mill circuits. Three stages of open circuit crushing were used to prepare rod mill feed. Grinding media was selected from various areas of the mine and tested separately. Impact tests on the three basic types of ore give Work Indices varying from to with two types ...

Ball Mill Working Principle Pdf

Mastercam mill essentials pdff free download ebook, handbook, textbook, user guide pdf files on the internet quickly and easilydesign handbook pdf 61139 grist mill lacombe la mill tap center cnc fanuc om series mastercam x5 mastercam vertical roller mill working principle. Read More; Dry Ball Mill Ball Mill For Sale Grinding Ball Mill

Working Principles Of Ball Mill

Working Principle Of Ball Mills. Ball Mill,Ball Mill For Sale,Working Principle Of Ball Mill. Working Principle of Ball Mill Zenith's ball mill belongs to a horizontal type and tubular running machine, having two warehous The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device In this ...

working principle of ball mills

Mechanical structure and Working Principle of ball mill. Working principle of ball mill. About Working principle of ball mill, you can click ball mill to know more about it. Previous: How to Make a Ball Mill Next: ..... Ball mill,Ball mills,Ball mill machines Machinery. Ball mill is the key equipment for grinding after the crushing process, ... there are dry ball mills and wet ball mills for ...

Ball Mill Working Principles

Ball Mill Working Principles . Ball Mill Operating principles, components, Uses A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis. Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific ...

Ball Mills

A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell. The nanostructure size can be varied by varying the number and size of balls, the material used for the balls, the ...

Latest Posts

- غسل الذهب مصنع للبيع عمان

- بيع معدات التعدين

- كسارات مخروطية مستعملة للبيع الجزائر

- مزادات مصانع كتلة الاسمنت الحالية

- افضل شركات مصانع الاسمنت في مصر

- الرطب عملية مطحنة الكرة في الذهب الطحن

- الشركات المصنعة للمطحنة العمودية في الصين

- ضمان الجودة الجديدة كسارة المطرقة

- مطرقة المعدنية مصنع للبيع المملكة العربية السعودية

- تجهيز الرطب من الكاولين كسارة مصر

- وحدات طحن وسحق الكوارتز والفلسبار

- كسارة الفك cj

- نظام جذب للغير مركز آلة طحن

- تاريخ التعدين في الجزائر

- قائمة كسارة الحجارة في pachamiwest bengal

- Jaw Crashers For Diamonds Mining

- Biaya Crusher Bb Pengurangan Ukuran Sampel

- Apple Grinder Price Apple Grinder Price

- Ore Dressing Process Of Iron In South Africa

- Build A Rock Jaw Crusher

- Used Zenith Xr Jaw Crusher

- Akd Emulsions Grinding Mills

- Boulder Crushing Machine Jual Price Di Bangladesh

- Hopper In Mining And Specification Lc3000x4000

- Cement Plant Feasibility

- 120tph Double Roller Crusher

- Smelting Titanium Slag

- Boston Mining Minerals Davao Oriental

- Process And Equipment Description In Gypsum Powder Production

- Scrap Metal Crushing Machine England