Calcium Carbonate Milling Process

calcium carbonate minning process

Calcium Carbonate Mining And Process In South Africa In Tirana Albania. ... Carbon grinding process When the large calcium carbonate is fed into ball mill it will be ground and the grain size can is between 0 074mm and 0 4mm in normal this final calcium carbonate can not meet the required size of .

Calcium Carbonate Powder Processing Plant

· Among this powder processing plant, HGM series calcium carbonate ultrafine powder processing plant is our star product, it can easily solve your problem. In the calcium carbonate crushing and grinding plant, you can choose the adaptable grinding mill types according to your requirement, the material's particle size.

How to improve the whiteness of calcium carbonate ...

Therefore, if you want to improve the whiteness of light calcium carbonate, can be in the process of digestion, or carbonization process, or cooked slurry to add reducing agent, complexing agent, such as sodium disulfite, DETA, triethanolamine and other agents compound, whiteness can increase 2 ~ 6%, the finished product whiteness can be increased to more than 94%.

Abrasion Characteristics of Huber's Ground Calcium ...

Since ground calcium carbonate is a naturally mined material, ... In this process, the GCC is slurried with water and a floatation chemical ... Since the product is already wet, economies of ultrafine grinding favor wet milling to the desired particle size. GCC slurry is then dried, which is an energy intensive process.

Calcium Carbonate Ultrafine Milling and Coating Process ...

A Greek company has three classifying and ball mill production lines with an annual output of 120,000 tons of 4100 micron calcium carbonate, 20,000 tons of 4mm bentonite and 5,000 tons of 663 micron talc. A Turkish company produces 60,000 tons of 840 micron calcium carbonate classifying and ball mill production line.

Ground Calcium Carbonate Process Diagrams

· Ground Calcium Carbonate Process Diagrams. I foud these diagrams for Ground Calcium Carbonate process in its all kinds. dry gcc. coated gcc. wet gcc. pcc. from chinese (micronchina ) and german companies ( hosokawa alpine ) i hope you find these diagrams useful . Attached Thumbnails.

Calcium Carbonate Powder Processing Plant | grindingequipment

· Among this powder processing plant, HGM series calcium carbonate ultrafine powder processing plant is our star product, it can easily solve your problem. In the calcium carbonate crushing and grinding plant, you can choose the adaptable grinding mill types according to your requirement, the material's particle size.

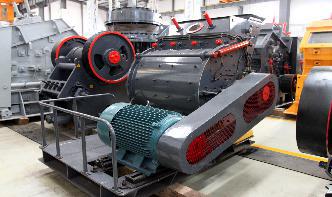

Calcium Carbonate Grinding Process | Mining, Crushing ...

· being processed by calcium carbonate griding equipment,whether the calcium carbonate micro powder can reach the fineness requirement . carbonate milling equipment is easy to operate and maintain. can meet the needs of the calcium carbonate processing equipment unit time. carbonate milling equipment must ...

USB1

Processes for making high quality PCC compositions, and the resulting PCC products thereof. A precipitated calcium carbonate (PCC) composition is prepared by a process comprising the step of wet media mill grinding an aqueous slurry of PCC made by carbonation of lime milk, with the grinding being done at a low solids content in a plurality of separate grinding stages, which can done while ...

Silverastone | Calcium Carbonate

Calcium carbonate is a relatively soft, insoluble mineral that is widely used to reduce cost and to control shrinkage in adhesive formulations. Calcium Carbonate is available in the widest variety of particlesize distributions of any mineral, and an optimum form for an adhesive and sealant appliion can .

Calcium carbonate grinding mill advantages and disadvantages

· Calcium carbonate grinding mill Manufacturer in China In China CLIRIK is a professional Calcium carbonate grinding mill manufacturers. We will provide you with jaw crusher, cone crusher, impact crusher, ball mill, raymond mill,hammer mill,ultrafine mill,vertical mill, vibrating screen, vibrating screen machine and other processing equipment.

Calcium Calcium Carbonate Crushing Process

Calcium carbonate crushing plant process is very simple it is the use of crushing transportation industrial milling equipment containing calcium carbonate mineral raw materials for processing can be used in the equipment are jaw crusher calcium carbonate milling machines conveyors etc.

MILL EXPERIENCE OF CALCIUM CARBONATE SCALE FORMATION IN ...

2 Figure 1. Calcium carbonate scale formation in green liquor pipeline at two kraft mills. CaCO3 has been identified as the main component of the hard scale, particularly at loions downstream of the dissolving tank [14]. A systematic study was conducted at the University of Toronto to examine how CaCO3 forms and what makes the scale hard [5].

Best Process for Coating Calcium Carbonate

· Re: Best Process for Coating Calcium Carbonate. 01/14/2010 5:39 AM. CaCO3 ground particle size 250 mesh to 400 mesh. Particle size required after coating 500 mesh (97%) and 600 mesh (97%) If necessary can even start with ground particle size 500 mesh or 600 mesh. Coating Thickness Approx 5% by weight.

How to choose a suitable calcium carbonate grinding mill ...

Answer (1 of 3): Tel: Calcium carbonate grinding mill is for superfine grinding materials such as kaolin, limestone, basalt, calcite, marble, talcum, gypsum, dolomite, mica, carbon black, graphite, fluorite, potassium feldspar, pigment, up to 200 kinds. Calcium carbonate grindi...

What are the contributions of ultrafine mills to the ...

Answer: In the calcium carbonate powder industry, the appliion of ultrafine mills is very extensive. This is an advanced equipment that promotes the deep processing of calcium carbonate. It has comprehensive mechanical crushing properties such as roller compaction, milling, and impact, and ha...

Calcium Carbonate | pulp paper mill

· · Calcium carbonate is used in paper mill as a filler material in the alkaline papermaking process. Now a days Calcium carbonate dominant over other papermaking filler materials; though at the first stage of papermaking kaolin was 1st choice. The main reason behind the preference of calcium carbonate is the demand for brighter and bulkier paper.

Calcium carbonate ultrafine powder grinding and ...

The processing of ground calcium carbonate is simply the process of using crushing and grinding equipment to process calcium carbonate minerals into various ... The production line adopts the international popular continuous production process: ball mill and air classifier system. The technological process mainly includes crushing ...

Processes | Free FullText | Calcium Carbonate as ...

Calcium carbonate, in a form usable as a mineral filler in such appliions, is typically produced either by crushing/milling (topdown process) or a synthetic precipitation (bottomup process). In the topdown process, natural calcium carbonate is crushed and ground down either by dry or wet milling to produce ground calcium carbonate (GCC) having a desired particle size distribution.

How to Choose a Suitable Calcium Carbonate Grinding Mill ...

· Wet Grinding Mill for Calcium Carbonate. Wet grinding of calcium carbonate obtains calcium carbonate powder by grinding the slurry form of raw material. And it mainly uses wet batching mill. Wet grinding mill produces calcium carbonate powder with D60=2μm and D90=2μm as paper filler and paint product.

Clirik CLUM Vertical Roller Mill Calcium Carbonate Powder ...

· Why Calcium Carbonate Powder Processing in Vertical Roller Mill is Popular? According our customer introduced, they had the largest calcium carbonate powder production base in vertical roller mill at domestic at present, their high quality calcium carbonate powder even can be exported to abroad more than 100 countries, because the caco3 powder had a widely use in various industries:

Calcium Carbonat (GCC) | Hosokawa Alpine

Calcium Carbonat (GCC) Calcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives. GCC is used as dry powder or slurry in many industrial appliions for plastic, paint, rubber, sealants or paper. Furthermore, a strong ...

Formation of Calcium Carbonate Scale and Control ...

Calcium Carbonate, continuous digester, kraft process, scale control, scale guard Introduction Calcium carbonate scaling of digesters and black liquor evaporators is the most frequently identified inorganic deposit problem in the kraft cycle. Scale buildup on heat exchangers leads to

Calcium Carbonate

Three major technological processes are used in the production of calcium carbonate fillers: milling, precipitation, and coating. However, most calcium carbonate fillers are processed by milling using a dry or wet method. Dry milling provides ultrafine calcium carbonate grades (particle size about μm).

Latest Posts

- تكلفة مصنع الكسارة

- المملكة العربية السعودية تصنيع الكرة مطحنة

- أسعار كسارة puzzolana

- مصانع التكسير المتنقلة sbm المستعملة

- مخروط محطم المملكة العربية السعودية

- كسارة الكوارتز الذهب الصغيرة للبيع

- بيع كسارة مخروطية japaness للبيع

- كسارة بعيدة

- التصميم الهندسي للحديد مصنع معالجة المعادن

- اليمن تستخدم معدات الطحن

- الهيكل التنظيمي للكسارات الحجر

- المملكة العربية السعودية تجار محطم

- آلة طحن الجبس

- حجر يستخدم في الغالب لمصنع كسارة الحجر

- أجزاء من كسارة خام الحديد تايوان

- Stone Cutting Machines Italy Stone Cutting Machines Italy

- Buy Vertical Grinding Mill Vertical Grinding Mill

- Jaw Fixed Die Crusher C H

- Coal Mill Rotary Classifier Wet

- Milling Machine Levelling Aciera

- Forsale Orecrushers Net Suppliers Of Crawler Mobile Crusher In Germany

- Dara 2 Anos Cantando Adele Rooling In The Deep Youtube

- Hydraulic Diagram Of Grinding Roler Suspension System Mps 5000b

- Jaws For Crushing Coal

- Bagazo De Chancadora De Martillo Ce Iso

- Paper No 6 Crusher

- Roller Steel Wheel Stand Assemblies

- Used Gold Washing Machine For Sale Uk

- Free Gold Dry Washer Plans

- Grinder Sanding Pad Vietnam