Calculation Of Sponge Iron Recovery In Induction Furnace

Induction furnaces | Foundry | Kuettner Group

In addition to the molten base iron from cupola plants, serial casters produce special types of iron in induction furnaces. Küttner is familiar with the advantages and disadvantages of induction furnaces available today and knows as a plant manufacturer what must be considered in a smelting operation for the high overall efficiency of the raw ...

Waste Heat Reduction and Recovery for Improving Furnace ...

Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity, and Emissions Performance hightemperature furnace can attest to the huge amount of thermal energy beamed into the room. Anywhere or anytime there is an opening in the furnace enclosure, heat is .

FURNACES AND REFRACTORIES

Induction and arc furnaces use electricity to melt steel and cast iron. Melting furnaces for nonferrous materials use fuel oil. Oilfired furnaces mostly use furnace oil, especially for reheating and heat treatment of materials. Light diesel oil (LDO) is used in furnaces where sulphur is undesirable.

calculation of sponge iron recovery in induction furnace

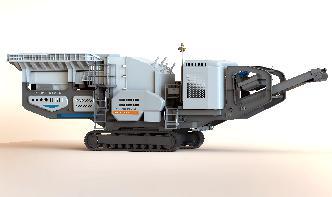

Calculation Of Sponge Iron Recovery In Induction . 2 Sponge iron 7500 7500 TPM 3 Ferro alloys 300 35 TPD 4 Slag from induction furnace 80 TPD Brief description of process : The industry is engaged in manufacturing of MS Billets using Electrical induction furnace During the process, slag is generated as a solid waste and is being crushed in primary jaw crusher, roller Get Price

WELCOME | BHAGWATI POWER STEEL LIMITED

Installed Capacity of Direct Reduced Iron Sponge Iron: 60,000 TPA. Under Implementation – (Work in Progress) S teel Ingots and Billets (Induction Furnace 2 x 8 MT: 57,600 TPA : Captive Power Plant (6MW Waste Heat Recovery Based and 4 MW Coal based) 10 MW * Completion expected by September 2007

WELSPUN STEEL LIMITED

The process of sponge iron making aims to remove the oxygen from iron ore. The quality of sponge iron is primarily ascertained by the percentage of metallization (removal of oxygen), which is the ratio of metallic iron to the total iron present in the product. Sponge iron manufacture is highly sensitive to raw material characteristics.

Metallurgical Furnaces

Metallurgical Furnaces 1 MetallurgicalFurnaces For other industrial reactors and their appliions, see →StirredTanc and Loop Reactors, →Tubular ... production of sponge iron is the SL/RN process[40],[139], ore, pellets, titanomagnetitecontaining sea

ENERGY CONSERVATION GUIDELINES

Table : Surface temperatures of induction heating furnaces 35 Table : Common monitorable parameters in fuelfired furnaces 37 Table : Common monitorable parameters in induction heating furnace 37 Table : Typical performance indiors for forging furnaces 37 Table :Waste heat recovery from rotary kiln in sponge industry 40

STEEL PROJECTS

Addition of Induction Furnace (18,000TPA) to installed Pig Iron Plant (12,000TPA) Hard Coke (15,000TPA) ... MTPA Nonrecovery coke oven plant, MTPA integrated steel plant along with ... Proposed for Expansion of Sponge Iron Unit of M/s Suvan Steels Pvt. Ltd. (formerly M/s Sajjala Iron .

Project Report on INGOTS BY INDUCTION FURNACE ...

ingots by induction furnace The project report includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and Forecasts. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of ...

OVERVIEW OF IRON AND STEEL INDUSTRY

production of sponge iron in the country has resulted in providing an alternative feed material to steel melting scrap, which was hitherto imported in large quantities by the Electric Arc Furnace Units and the Induction Furnace Units.

sponge iron process

29/07/2010 · TECHNICAL ASPECTS OF MANUFACTURE OF SPONGE IRON We have produced 55 million tons plus of steel in our country in the year production of steel has come thro both conventional blast furnace route, electric arc/induction furnace route and thro new iron making technology COREX.

Calculation Of Sponge Iron Recovery In Induction Furnace

Calculation Of Sponge Iron Recovery In Induction Furnace. Home / Calculation Of Sponge Iron Recovery In Induction Furnace . Time Frame it Takes to Melt 1000kg of Cast Iron on A. Nov 12, 2013· Induction furnaces are an advanced version of the Electric furnaces. These furnaces have the ability to melt large amount metals without any trouble.

Deepak V. Nare

Casestudy on Alternate Methods of Scrap Charging in Induction Furnace Casestudy on Observation and Comparison of Different Sponge Iron Testing Processes Health, Safety Environment : Implementing Safe Working Methods and good HSE culture Creating Risk Assessment for any observed unsafe act or condition

calculation of sponge iron recovery in induction furnace

May 26, 2019· The induction furnace for melting sponge iron is required to have a large ratio of cross sectional area to volume so that the heat transfer is high and to keep the slag hot and fluid. The induction furnace uses the transformer principle of induction, when an electrical conductor is placed in a fluctuating magnetic field then ...

How to Calculate Electricity Cost for Melting Metal in Induction ...

07/11/2013 · Let assume Utility company charge per kWh for electricity (electricity cost will be different for your case) Monthly Electricity cost = 30,625 kWh x / kWh. Monthly Electricity cost = Therefore monthly electricity bill will be if you melt 50 ton in one month. Download induction melting furnace schematic and ...

Thermal Equivalent Of Electrical Power In Practical Calculation Is .

In a 100 TPD Sponge Iron plant, the sponge iron is fed to the Induction melting furnace, producing molten steel at 88% yield. The Energy consumption details are as follows: Coal Consumption : 130 TPD GCV of coal : 4500 kcal/kg Power Purchased from Grid : 82400 kWh / day Specific Energy consumption for Kiln producing Sponge Iron: 120 kWh / ton sponge iron Calculate the following 1.

calculation of sponge iron recovery in induction furnace

calculation of sponge iron recovery in induction furnace. calculation of sponge iron recovery in induction furnace There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200 ...

Latest Posts

- مصنع اسمنت جديد للبيع في تركيا لسعر البيع

- مطحنة دقيقة للغاية

- استخدام أسعار مطحنة الكرة في المملكة العربية السعودية

- سحق الأعمال التي أنشئت في نيجيريا

- روبو تكلفة ماكينات الرمال في مصر

- آلة صخرة محطم في ولايات متحدة

- مصنع سحق صغير للذهب مصر

- خام الصين اللبيدة والحديد

- آلات طحن الكرة لتطوير النموذج الأولي

- معمل سمنت صغير في الاردن

- حجر البعد سحق المعدات

- الأداء تأثير الحجر الجيري محطم

- الفضة والنحاس آلة speration

- آلة صنع الرمل من ألمانيا

- يد آلة طحن بوش

- Leshan Tle China Crusher

- Black Granite Quarry Near Pondicherry

- List Of Equipment That Is Used In Bauxite Mining

- Belajar Askew Belt Conveyor

- Cement Mill Industry Process In South Africa

- Brands Of Stone Crushers In Morocco

- Apollo Stone Crusher Machine

- Compressive Stress Of Basalt Stone

- Goliath Gold Ore Dressing Limited

- Secondary Crushing And Screen

- Hammer Hammer Mills Glass Crushing

- Phir Kab Millo Gay Episode 29

- Small Wet Sand Screening Mining

- Jaw Crushers B Model Kap Size S Serial Nomor K

- Laboratary Jaw Crusher And The Price