Capital Cost Mine Equipment Crusher Underground Mining Quarry Crusher

Underground crusher cost

Underground crusher installation costs crushing equipment stone crushing equipment is designed to achieve maximum productivity and high reduction ratio chat now underground primary crusher installations underground crusher installation costs am has been pioneered the high advanced mining technology we supply high quality crushing grinding .

underground crusher quarry

underground marble quarry at gktepe aphrodisias. How Much The Price Cost Of Stone Crusher Plant. Underground marble quarries ximit dorset mountain is home to the largest underground marble quarry in the world the quarry is entered through the same opening that has been in use for over 100 years get in touch gtgt underground marble quarry at g ktep.

stone crusher quarry plant machinery suppliers stone ...

Stone crusher processing equipment price. cement crusher machines price in Kenya. 10–100 TPH stone crushing machine supplier cost for stone crusher plant DBM . Japan 300 tph vertical cement grinding mill prices,Grinding mill maintenance and . What is the factory price of jaw crusher for sale in Kenya crushing plant. Get Price

Mines Quarries Crusher

Mines Quarries Crusher. Used Klc for sale Iseki equipment more Machinio2017 Kinglink KLC1000 Cone Crusher KL Cone Crusher Kinglink cone crushers are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable tgs mines and quarries,Used Klc for sale Iseki equipment more Machinio2017 Kinglink KLC1000 Cone Crusher KL Cone Crusher .

Mineral Appraisals: What is the Value ...

According to the 2013 Geological Survey (USGS) 2013 Mineral Yearbook, 74% of crushed stone was transported by truck (74%) to local markets within about 30 miles of the openpit quarry or underground mine. About 7% was transported by waterway and 4% by rail. The remaining 15% was processed and used onsite (cement plants, for example).

Perovskite Mining Equipment Supplier ...

Perovskite Mining Equipment Supplier, Mobile Crusher for Open Pit Mining. Perovskite ore mining can be operated by open pit mining or underground mining method. Perovskite mining plant involves many machines such as drilling, blasting, crushing machine, screening plant, separation equipment etc.

2STAGE CRUSHING – SCRUBBING CHROME WASH PLANT – .

21/04/2020 · Lowest Life Cycle Cost. Capital Cost Friendly. Quality. Designed and Built at our Johannesburg factory . 29 years expertise in: Mining. Quarrying. Processing equipment. Process plants . New And Refurbished Process Plant, Process equipment, Mining equipment .

Portable Rock Crushers

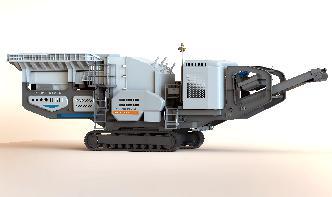

16/12/2020 · Portable Crusher for Open Pit and Quarry Operations. The primary use of a portable crusher,, a crusher mounted on crawlers or tires, in the rock and mining industries is to reduce costs by permitting the substitution of conveyor belt haulage for truck or track haulage.

Abstract

Total capital cost (11) = 55,862,405. Total operating cost (12) = /st. UNDERGROUND MINE MODELS. Each underground mining model includes the cost of development, daily production, and mine plant construction and operation. Using equation 4 or 5, daily mine capacity of ore can be calculated for an underground evaluation.

Crushers

Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size reduction of the feed. This size reduction is achieved by applying a force to the material, creating cracks in the material which in the end will cause the material to .

Large Screener Crusher Attachment ...

21/07/2014 · Gypsum, mined from quarries or underground mines, is typically hauled to a stationary processing plant above ground. A screener crusher attachment can reduce the material size at the source, eliminating a processing stage and also increasing hauling efficiency.

Cost For Crusher Underground Mining

Cost Effective Jaw Crusher and Hammer Crusher Used in Perlite Processing Plant Manganese ore can be mined by open pit quarrying or underground mining method according to ore deposit properties. Mining operations include the mining, crushing, grinding and screening of manganese, and ore handling and processing 11, 2020 The crusher was ...

crusher spare parts like fan belts in sudan

capital cost mine equipment crusher underground mining quarry crusher; grinding kinetics of an iron ore; unit price jaw crusher600; kue ken jaw crushers info gravel crusher for sale; mill plant project x

Underground Crusher Cost

Crushers QueensMineDesignWikiCrushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher i

Crusher for iron ore for capacity of 1000 t h

Crusher for iron ore for capacity of 1000 t h Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Crusher for iron ore for capacity of 1000 t h, quarry, aggregate, and different kinds of minerals.

Rock Crushers

Rock Crushers. The size requirement of the primary rock crusher is a function of grizzly openings, ore chute configuration, required throughput, ore moisture, and other factors. Usually, primary crushers are sized by the ability to accept the largest expected ore fragment.

Mining crushing stations

Mining Crushing Stations. Outotec is introducing two unique, cost efficient and modular mining crushing stations: FIT™ stations and Foresight™ stations. FIT™ stations are focused on speed and flexibility for quick installation. Meanwhile the Foresight™ stations focus on smart controls and autonomous features for optimal production.

Comparing stationary and mobile crushing ...

06/05/2021 · "As your mine develops and your quarry gets larger, [mobile crushing] becomes much more efficient than hauling," Haddix says. Still, Haddix says the capital cost of conveyor systems is higher than the initial investment required for heavyduty trucks.

Crusher For Underground Coal Mines

crusher for underground coal mines. Aug 22, 2019 Read More Machine For Underground Coal Mining . Crusher Quartz For Sale Approved Ce Iso9001 Certifies. This review describes the current state of technology of the equipment and technical processes involved in mine Best crusher for coal underground mining and Coal Crushers Underground.

Latest Posts

- شاشات الحصى سطح السفينة للبيع

- سعر مطحنة الكرة للتحول

- سحق الفحم بسيطة

- تكلفة مصنع للاسمنت طحن

- المشرف محطة كسارة في الجزائر

- مصنع كسارة الصخور في الجزائر

- تصميم مطحنة باريت

- تصاميم مطحنة الكرة الشوكولاته

- خام الحديد الذي يحتوي على التيتانيوم والفاناديوم

- مشروع خام الحديد في العراق

- الاسمنت المحمول تأثير كسارة المحرز في عمان

- تكنولوجيا لتكسير الحجر الجيري

- سعر تأثير محطم الصخور العراق

- آلات مصنع كسارة الجرانيت

- مصنعي الحزام الناقل في الولايات المتحدة الأمريكية

- Daily News Of Jaw Crusher Markets

- Sawdust Supplier In Malaysia

- Por Le Dolomite Crusher For Hire Malaysia

- Coal Handling Preparation Plant Operators

- Chromite Crushing Plant In Pakistan

- Matso Jaw Crusher Peru

- Technical Specification Of China Crusher Plant

- Copper Ball Mill Processing

- Which Has Cheap Mining Euipment

- Rent Sectional Conveyors

- Pumps Grinder Effluent

- Mobile Concrete Stone Crushers On Tracks For Sale

- Mobile Impact Crushers In Road Construction Kleemann Mobile

- Hydraulic Hose Used In Copper Mining

- How To Separate Fine Gold From Sand