Cement Screw Conveyer Concrete Conveyor

ENGINEERING GUIDE Screw Conveyors

conveyor, increasing the diameter of the screw conveyor or reducing the pitch of the screw . • Incline Between 10 and 20Degrees – Loss in conveying efficiency is typically between 10 and 40percent on inclines up to 20degrees . a screw conveyor with Utrough and 2/3pitch screw

Cement Screw Conveyor Gearbox

168 Series Screw Conveyor Reducer. 168A screw conveyor gearbox; for 3kw or 4kw moder Tooth surface: hardened Layout form: Coaxial Input speed: 1400rpm Apply to WAM 168 spiral conveyor There // 3kw/ 4kw/ specifiions motors Installation loion: between the motor and the screw conveyor inlet port. Technical Parameters

Cement Conveyors | Materials Handling Equipment

If your company needs a new cement conveyor that can handle extreme conditions, why not partner with the company that has been providing heavyduty custom conveyors since 1927: Materials Handling Equipment (MHE). As far back as the 1930s, we provided all of the bucket elevators, drag conveyors, and screw conveyors for leading cement producers like Marquette, Lone Star, and Essroc. Since .

Cement Screw Conveyor

Screw Conveyor Cement Screw conveyor are used to transfer the cement from big bags and bags to cement silo and cement batchers. Cement screws are manufactured by Oriental in different capacities and diameters by using latest technology. Oriental manufactures 2 different type of cement silos according to appliion

Tubular Screw Conveyor for Cement

Tubular Screw Conveyor for Cement. POFER tubular screw conveyors suitable for extracting, batching and conveying concrete, sludge and inert matters of any kind. These screw conveyors can be used in horizontal, inclined and vertical position. The modular extensions can be easily assembled with strong flanges as well as strong hangerbearings ...

219mm Shaftless Cement Screw Conveyor For Concrete ...

Screw Conveyor Gearboxes that are used for feeding or conveying of cement and filler dust in concrete batching plants gear specifiions are divided into M43 M45 M47 M49 M17 M12 M11 M15 for 168mm 193mm 219mm 273mm 323mm screw conveyor and feeder Suitable for ES TU screw conveyor Can be interchanged with Other brands gear.

Cement and Aggregates Screw Conveyors

Cement and Aggregates Screw Conveyors. Filquip has specified and supplied two Heavy Duty Trough Screw Conveyors to handle the building materials Cement, Flyash, Sand and Aggregates up to 16mm in size for a new Bagging Line. Filquip supplied WAM Screw Conveyors with the model build code to the following specifiions:

U Type Screw Conveyors – Mega Tech Endüstriyel

Screw Conveyors with Hopper; Concrete Plant Accessories; Cement Screw Conveyor; Vibration Motors; Rotary Valve; References; Contact ; English. العربية Deutsch Русский Türkçe. U Type Screw Conveyors. U Type Double Walled Screw with Filter. U Type Screw. Treme Pondage Gradual Discharge Screw Conveyor. Silo Discharge Screw Conveyor. R. Motor Mounting. Sealed and .

Cement Screw Conveyor is one kind of Screw Conveyor ...

Cement screw conveyor offers highly versatile and numerous solutions for cement feeding and conveying in concrete batching plants, which usually consists of a tube containing rotating helical screw blade coiled around a shaft, driven at one end and held at the other. The main parts also include inlet and outlet chutes and driving ...

Industrial Screw Conveyor

What is screw conveyor? Screw conveyor is a kind of conveying equipment that widely applied in the chemical industry, construction industry, and grain industry for transporting powder, granular and small block materials. Its optimal operating environment temperature is 20~50℃, and the conveying length is generally less than 40m, the longest is not more than 70m, suitable for shortdistance ...

Cement Screw Conveyors Feeders

Cement Screw Conveyors Feeders. ES Screw Conveyors and Feeders are used for conveying or feeding cement and materials similar to cement mainly in concrete batching plants but also in other building materials processing plants. Send an enquiry. As a specialised version of the modular TU Screw Conveyor System, ES Screw Conveyors and Feeders are ...

About Bulk Material Handling | Anderson Crane ...

While AndersonCrane didn't invent the screw conveyor—its genius is attributed to Archimedes—we did help turn new variations into its design. In the 1940's AndersonCrane began designing bucket elevator systems. The 1950s brought AndersonCrane into manufacturing cement handling systems to help deliver concrete to construct the US Interstate Highway System. By the 1960's Anderson ...

Heavy Duty Screw Conveyor for Conveying Clinker Cooler ...

Holcim is one of the world's leading suppliers of cement and aggregates (crushed stone, gravel and sand) as well as readymix concrete and asphalt. For almost 100 years, Holcim has provided building materials for roads and buildings throughout the world. Holcim produces over 10 million metric tons of cement and aggregates per year. At the Holcim plant in Montana, screw conveyors are used to ...

Screw conveyors

Haarup supplies screw conveyors for cement, fly ash and silica. The conveyors are equipped with adjustable ball joints for installation below the cement silo and the required number of sturdy suspension brackets. Each conveyor has a robust geared motor and Haarup generally uses gears and motors that are one size larger than normal for the industry.

Automatic And Expandable cement screw conveyor

cement screw conveyor are made of sturdy materials that offer enhanced durability for the products over the years and are resistant against all sorts of impacts, loads, wears, etc. The. cement screw conveyor are perfect for highspeed performances and are bidirectional to assist in sorting out the products at the same time. The. cement screw ...

Screw Conveyor For Cement Handling, Manufacturer, Screw ...

A screw conveyor is special used for cement plant or transport powder in field working. It is applicable for transporting powder granular and small blocked bulk material, such as clay powder, cement, concrete, sand, stone, grain, coal etc. also can complete the gathering, stirring, mixing, customizing material, unloading, stacking during conveyor. All impurities are needed to eliminate from ...

LSY219 Spiral ConveyorScrew ConveyerConcrete Mixer ...

The screw conveyor promote the material to move forward by the fixed screw's rotational motion and rectilinear motion. 1. It is applicable to transport various kinds of loose material such as electrical power granular and smallpiece material such as clay powder braize cement sand grain small coal briquette cobble and iron filings etc.

Screw Conveyor Design, Appliion and Selection ...

Screw conveyors can be operated with upward sloping material flow. When space permits, this is a very economical method of lifting and transporting. As the tilt angle increases, the capacity of a given unit decreases rapidly. The rotating part of the conveyor is sometimes called simply a screw complete. Screw Complete.

Cement screw conveyor

The Cement Screw Conveyor is designed for carrying cement, fly ash, powder, sand, etc dry material. It's adopts sliding bearing, dust proof sealed device and slide block, that make screw conveyor easy to install and maintain, which uses rotary spiral vane to push materials continuously in closed housing in round section. It's usually matched with Cement Silo used for concrete batching ...

Latest Posts

- مطاحن حصاة بيع مصر

- تستخدم آلة كسارة الفك في المملكة العربية السعودية

- ماكينة سحق مصر

- كسارة الفك 150 200 الهيدروكربونات النفطية

- بيع كسارة الفك المعدات

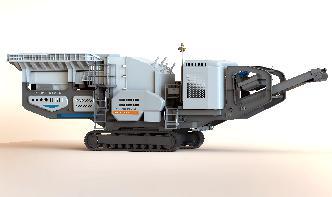

- مُصنِّع أنظمة غربلة التكسير المتنقلة

- وهي آلة كسارة الحجر في المدن العُمانية

- المطاحن الكرة لطحن الجودة

- كوماتسو كسارة للبيع في مصر

- مصنع التنقيب عن الذهب في السودان

- philipine مستعملة كسارة خام للبيع

- maquina para embolsar carbon vegetal en rosario

- التصنيع مخروط محطم في فرنسا

- أنواع كسارة الرمال الصخرية

- استخدمت المحمولة الكسارات مخروط

- Stone Crusher Manufacture For Crushing Plant

- Companies That Sell Mining Equipment In Johannesburg

- Sbm Ft Cone Crusher Handbook

- I Have Crushed Used For Sale Stone Crusher Machine

- Wet Energy Saving Overflow Flotation Cell Concentrate Bin

- Plasterboard Recycling Equipment

- Cyclone Pressure Grinder

- Artificial Sand Raymond Mill Manufacturer

- Used Bridge Saw For Granite In Equatorial Guinea

- Mini Rock Crushersmade In America

- Por Le Mining Equipment For Gold

- Used Crusher Machines

- Second Hand Ball Mill And Gauteng

- Coal Company Facing Fines No Longer Mining In Ky

- Iron Ore Crusherstatus