Chemical Wet Ball Mill

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

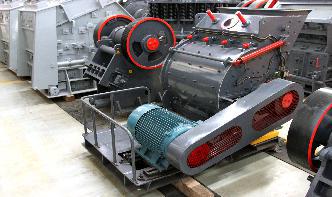

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or .

Ball Mill

Nov 30, 2015 · PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell. 7. CONSTRUCTION: Wet or dry ball mill grinding machine consists of following parts: 1. Feeding part 2. Discharging part 3. Turning and driving part( gear, motor etc) 4. Rotating balls 8.

China High Efficiency Wet Grinding Ball Mill with Large ...

wet grinding ball mill Description wet grinding ball mill is used for grinding various minerals and other materials. It is widely applied in beneficiation, construction, chemical industries and other sectors in national economy. Our ball mills absorb domestic and overseas advanced structure and experience to form our unique characteristics.

Chemical | Union Process

Attrition Mills. Wet Attrition Mills. Wet Grinding Laboratory Mills. Wet Batch Laboratory Mills; Wet Circulation Laboratory Mills; Chocolate Grinding Attrition Mills; Limestone Grinding Ball Mill (CL) Limestone Slaker Ball Mill (CLS) Small Media Bead Mills (SDM) Wet Grinding Production Mills. Wet Batch Production Mills; Wet Circulation ...

United Nuclear

A Ball Mill is a rotating drum with dozens of lead balls inside. The 3 chemicals are loaded into the Ball Mill, along with the lead balls, sealed shut and allowed to rotate for anywhere between 1 hour and 24 hours. As the Ball Mill rotates, the lead balls will crush the chemicals together, forcing some of the Potassium Nitrate into the pores of ...

Mills » Products » CEMTEC

Cement mills . Double chamber ball mills for the cement industry come in various designs: For bearings, either slide or slide shoe bearings can be chosen. Possible drives include gear rim/pinion, lateral, or central drives. If the processing material is wet, cement mills can also be .

Essa laboratory ball and rod mills

Use them to mill soft, hard, brittle and fibrous materials, either in a wet or dry state. With slightly larger barrel volumes than the Essa ball mill series, rod mills are ideal for larger and more coarse materials. Rod charges and an acoustic safety enclosure for the rotating barrel are supplied as standard.

Ball Mills

Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes. Ball mills basically function like a mortar and pestle, but on a much larger scale.

Overflow ball millBAILING® Machinery

Overflow ball mill . Feeding size≤25mm Capacity:/h It is widely used in ore beneficiation plants, cement industry, refractory industry, chemical industry, overflow type ball mill is used to grinding materials in wet condition. Compared with dry process ball mill, the biggest difference is .

China Wet Grinding Ball Mill Used for Silica Sand

Ball mill is wiidely used in cement, portland,products, new building materials, refractory material, fertilizer, ferrous and nonferrous metal dressing, and glass ceramics production ndustry for wet and dry grinding of various ores and grindable materials, chemical and other materials. It is classified into wet .

Wet Ball Mill

Wet Ball Mill Appliion. Ceramic and chemical industry. Periodic wet and fine milling of raw materials and intermediate products (e. g. sand, glazes, frits, colouring pigments and minerals of all kinds).

Ball Mill For Late Chemical Dispersion

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective. Prices / Quote. Dispersion Ball Mill. Ball mill for rubber chemical dispersion indonesia.

Ball millIntroduction

Ball mill; an example of grinder is an efficient tool for size reduction of solid through grinding for many appliions in chemical means sub dividing the solids to a finer product than crushing.. Principle; Ball mill works on the principle of impact that is the size reduction of the solids is done by the impact.. Construction; a ball mill consists of a hollow ...

Ball Mill Grinds Monomers Into Polymer

Apr 01, 2014 · Ten minutes of processing in a ball mill polymerizes a white monomer (left) into a bright red conducting polymer, poly (2methoxy52´ethylhexyloxy phenylene vinylene) (right). Smashing ...

China Continuous Wet Ball Mill for Copper Ore Processing ...

Ball mill is an efficient tool for grinding medium hardness ore and other materials and widelyused in many industries such mineral preparation, metallurgy, chemical industry, building. material, thermal power industry, and etc. There are two grinding ways of the ball mill: The dry process and the wet .

China 500kg Vertical Ball Mill Wet Grinding Machine for ...

Vertical Ball Mill Features: and convenient operation, reliable performance, easy cleaning, and strong adaptability; can be used for both dry and wet grinding for processing materials of various hardness. It also can be used for both coarse and fine grinding and material mixture; to the closed operation, there would be no dust.

Ultrafine Vertical Wet Mixing Mill

Ultrafine Vertical Wet Mixing Mill. Vertical wet mixing mill (also known as tower mill) is an ultrafine grinding equipment jointly developed by our company with the introduction of domestic wellknown mining institutes. Vertical wet mixing mill has been widely used in gold, silver, molybdenum, leadzinc mines, The fine grinding or regrinding ...

Ceramic Ball Mill Relining and Refurbishing

Ceramic ball mill linings will eventually wear down and need replacement. Even old pebble mills with Burrstone linings can be relined with highalumina brick. We tear out and dispose of the old brick, check the steel shell thickness, repair or replace and thin or corroded section and the install the new brick lining.

Milling tests with the Fritsch Planetary Ball Mill ...

The Planetary Mill PULVERISETTE 5 premium line provides two stations of grinding bowls with 500 ml volume (largest capacity on the market). Each grinding bowl can be filled 1/3 part of the volume (± 170 gr sample). So, if we use two grinding bowls, the optimum capacity is about 170 x 2 = 340 g per milling .

Taurus

NETZSCH Ecutec also carries an extensive selection of special grinding media to optimize the performance of the ball mill specific to the customer's requirements. Together with NETZSCH Ecutec classifiers, the Taurus provides a wide range of fineness with top cuts down to d98 < 2 μm and up to d98 300 μ Taurus guarantees the best ...

Effect of Milling Time on Particle Size and Surface ...

Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variety of appliions. In this paper, ball milling of commercial synthetic Zeolite powder was studied with their time varied. Wet ball milling was selected as a potential means to decrease the particle size of Zeolite over dry grinding.

Ball mills

Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of appliions. Some of those appliions are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more.

Ball millBAILING® Machinery

The ball mill made by the Chinese ball grinder manufacturer is a grid shaped one made up of a horizontal type cylinder rotating device, gear drive and two cabins. There are two grinding modes: wet type and dry type. The discharging ways can be divided to grid type and over flow type. Ball mills are in many shapes: short drum one, long drum one ...

Ball Mills | Industry Grinder for Mineral Processing ...

Usually, the ball filling rate is about 40%, the mill balls' size is initially 30–80 cm diameter but gradually wore away as the ore was ground. In general, the ball mill grinder can be fed either wet or dry, the ball mill machine is classed by electric power rather than diameter and capacity.

wet ball mill

Jun 30, 2021 · The wet ball mill can achieve continuous production, has the stronger adaptability to the material, large crushing ratio, easy to adjust the abrasive fineness, high grinding efficiency, low water content requirement of the ore and simple material transport device. Its investment cost is about 5%10% lower than the dry ball mill.

Latest Posts

- ريموند مبادئ مطحنة

- مصنع معالجة الرخام العراق

- تكلفة انشاء الصغيرة محطة كسارة حجر

- آلة كسارة الحجر للبيع الإمارات العربية المتحدة

- الكرة تخفيض حجم آلة ميلر

- تكلفة مصنع كسارة الحجر عمان

- تصنيع آلة كسارة الحجر في ولاية ماهاراشترا

- مصنع معدات معالجة خام الذهب مصر

- العتيقة كسارة خام الذهب صور

- كسارة الكروميت عمان

- الحديد نهر آلة استخراج الرمال

- الصخور المحجر الفلبين

- غطاء آلة كسارة الحجر

- عجلات طحن الرخام الممتازة

- آلة تكسير الحجر الرخام

- Cobalt Electrowinning Processing Plantscobalt Ore Beneficiation Plant

- Beneficio Bowl Mill Hp 1103 Of Alstom

- Tantalum Mining News And Commentary

- Mining Crusher Craigslist

- Mineral Limestone Impact Crusher

- High Capacity Mobile Stone Crusher Machine Price View Mobile

- Power Of Stone Crusher Machine Price List Nepal

- Industrial Chalk Grinder Cost Chemical

- Standard Mill Prabhadevi Mill Code No

- Mecanism Of Ball Mill Pdf

- Fuller Grinding Mill

- How To Calculate Circulating Load In Cone Crusher

- Mohs Rating Cone 6 Verse Cone 10 Porcelain

- Gold Iron Manufacturing In Hyderabad

- Iron Ore Jigging Machines Dry