Coal Mill And Coal Crusher

Roll Crusher

Roll Crusher. For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal. Doubleroll crushers consist of two rolls that rotate in opposite directions. Normally, one roll is fixed while the other ...

Pulveriser in Thermal Power Plant | Bowl Mill | Ball Mill

In bowl mill pulveriser raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl. Bowl is made to rotate at medium speed for proper pulverization of coal. Springs exert necessary pressure on rolls for grinding. Hot air through the mill besides removing coal moisture, picks up the lighter particles and takes them through the ...

Crusher

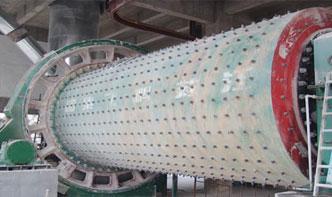

In the coal industry, which grew up hand in hand as the preferred fuel for smelting ores, ... A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill. In this context, the SAG mill and ball mill are considered grinders rather than crushers. In operation, the raw material (of various sizes) is usually delivered to the primary crusher's ...

Coal Crusher_Coal Pulverizer_Coal Crusher Machine_Coal ...

Coal crusher equipment commonly used in coal crushing include: jaw crusher, impact crusher, circular vibrating screen. We can also add sand making machine and other equipment according to special demands to achieve a finer processing to coal. Heavy Industry produced Coal crusher is a highly wearresistant coal crusher, with the feature of simply structured, high crushing ratio, high ...

hammer coal crusher, hammer coal crusher Suppliers and ...

Laboratory coal sample analysis equipment hammer crusher for mining primary crushing, lab hammer mill Lab hammer mill technical parameter Model No. It is suitable for grinding the material such as coal, coke, sand,stone, rock, limestone, concrete, metal, copper, coltan ore, gold, pyrite ore and so on. GUANGMING involved in lab sample preparation and sample analysis equipment more than 30 years ...

Coal Mining Process Flowchart

Coal Mining Process Flowchart. Question: Can ZENITH make an overview of coal mining process flowchart for me? Answer: Thanks for your question. Firstly, large coalbearing stones are crushed by coal crushers to a size of 20 to 25 mm, and then they are fed to coal bunkers. Through the vibrating screen, those crushed coal stones are continuously enter the coal mill. Coal gets ground by grinding ...

coal hammer crusher, coal hammer crusher Suppliers and ...

Coal Hammer Crusher High Quality Stone Glass Clay Coal Mini Hammer Crusher Mill For Sale. Up to 5 years warranty. US / Set. 1 Set (Min. Order) CN Henan Hongji Mine Machinery Co., Ltd. 2 YRS. (2) Contact Supplier. 1/6. Crusher Hammer Apply To NP1620 Impact Crusher Replacement Parts Blow Bar Blow Hammer. Up to 5 years warranty . US / Piece. 1 .

China Crushing Equipment Crusher manufacturer, Grinding ...

Flotation Equipment, Screening Equipment, Classifying Equipment manufacturer / supplier in China, offering Coal Crushing Machine/ Coal Crushing Equipment / Coal Crushing Machinery / Fine Coal Crushing Machine, China Real Manufacturer of High Quality Cone Crusher Hard Stone Crusher for Sale, Sample Operation Ore Grinding Equipment Ball Mill and so on.

Coal Crushing Handling System

Finally, the coal is sent to the bowl mill where coal is further crushed into powder. And this powdered coal is used for the generation of the electricity. We are providing the equipments that are required by this coal crushing system and the coal handling system.

Vibration Monitoring of Industrial Coal Crushers ...

· Industrial vibration sensors for coal crushers pulverizers form an integral part of the production processes at thermal power stations, sugar mills, mining industry, and more. Most coal handling systems meet the demands of a thermal power plant by loading and unloading coal to a stockpile, feeding the coal crushers, and sending the pulverized coal.

difference between rb1 rb2 coal

· > Crusher and Mill > difference between rb1 rb2 coal; Print. difference between rb1 rb2 coal. Posted at:November 9, 2012[ 3028 Ratings] south african coal difference between rb1 rb2 – Gold Ore Crusher. – UPDATE 1India's Jindal buys Kiepersol coal mine . The energy content of the coal is comparable to standard South African RB1 coal but . »More detailed ...

China Coal Grinding Mill/Coal Mill Pulverizer/Coal ...

Coal grinding mill/coal mill pulverizer/coal pulverizing machine is suitable for processing various nonflammable and nonexplosive mineral materials with Moh's hardness less than and humidity less than 6%, it is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc, . The granularity of the finished powder size can be adjusted between ...

What are Coal feeders? Principle, components ...

· Coal Feeder is a device that regulates the amount of coal to be supplied into the Coal Mill. The amount of coal is regulated according to the needs in the boiler combustion chamber (furnace). The number regulation system in the coal feeder can be done in two ways based on the type, namely by weight fraction or coal volume fraction. Principle of Coal Feeder: Coal that has been crushed with a ...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

consist of a crusher followed by a SAG mill followed by a ball mill. In this context, the SAG mill and ball mill are considered grinders rather than crushers. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw Grade (K Cal/Kg) % Ash + Moisture A >6200 B 5601 ...

Coal Crushers, Shredders, Mills for Mining Power ...

Coal Crushing. The record speaks for itself: since 1908, hundreds of millions of tons of coal have been reduced using American Pulverizer machines. We are the standard of comparison for central stations, industrial power plants, and mine preparation plants around the world. We make many types of coal crushing equipment, like our ACC Series ...

coal mills crush

Coal mill is also known as airswept coal mill coal crusher or coal grinding mill. It is a kind of grinding machine which can conduct both drying and grinding. Coal grinding mill is developed based on traditional ball milladd the drying and airswept device in the ball mill system making it more convenient to conduct coal . Chat Online ; Ball Mill Ore Grinding Equipment for SaleJXSC Machine ...

how to replace the vertical shaft in a coal mill

Welcome To Znith. Founded in 1987, Znith has attained 124 patents on crushers mills over the past 30 years. More than 30 overseas offices not only manifest our popularity, but also solve your puzzles quickly in operation. So if you are looking for crushers or mills.

Coal And Ring Granulators

This type of crusher is extremely popular in power plants/medium sized industries for crushing of coal for boiler. They are also used for gypsum, salt, chemicals and mildly hard minerals. Also available from our manufacturing range : Jaw Crushers, Reversible Impactors/ Hammer mills, Vibrating Screens, Rotary Screens Vibrating Feeders etc.

Liberation characteristics of coal middlings comminuted by ...

· Considering the low limit of separation size for coal, a jaw crusher and a ball mill were selected as the experimental devices to achieve the similar size distribution of the product. Full densimetric analyses and sectional micrographs on sized fractions of coal middlings prior to and after comminution were conducted to compare the discrepancy of liberation degree between these two .

Pulverizer Crusher Plant India | Crusher Mills ...

Coal Mill Pulverizer in Mumbai, India | Stone Crusher. raymond coal mill pulverizer in thermal power plant ppt. . project report of 150 tph stone crusher in india; coal handling plant for coal size 5 .

Fire and Explosion Prevention in Coal Pulverizing Systems

MILL COAL FEED COARSE WET COAL FEEDER PRIMARY AIR CRUSHER. DRYER BYPASS DAMPER Figure 4 Ball Tube Mill Pulverizing System 8. Operate at system primary air temperatures below those historically used as normal. The trend is toward classifier outlet temperatures of 125 OF away from 150 160 OF. In addition to the above, some utilities have utilized what has been termed .

Coal | McLanahan

McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and fines. Employing the basic reduction principles, McLanahan crushers reduce coal at maximum volume using compression, impact, attrition and shear ...

Hammermill Crushers | McLanahan

The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm). Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestone.

Coal beneficiation plant, coal crusher, coal mill, coal ...

Impact Crusher. Hammer Crusher. Ball Mill. Raymond Mill. Vibrating Screen. Coal beneficiation process. About Coal Beneficiation, there are three kinds of processes may be performed at the plants: (1) Sizing, controlled by a crushing and screening process. (2)Increasing heating value, by removing noncombustible ash and rock by gravity separation.

Coal Double Roll Crusher VS Coal Single Roll Crusher

Coal double roll crusher: raw materials, secondary raw materials and byproducts such as clean coal, coal with rock; Coal Single roll crusher is used for grain size reduction for products ranging from soft to mediumhard; Mode Of Operation. The double roll crushers are individually driven in counter rotation by ample drive arrangements. The ...

Latest Posts

- معدات تعدين الذهب على نطاق صغير بيع اليمن

- أجزاء كسارة الفك في الإمارات العربية المتحدة

- سحق إجراءات تشغيل الحصى

- تشخيص معدات تعدين الفحم

- حارس شاشة الخصوصية للهاتف المحمول

- قائمة مراجعة صيانة مطحنة الحديد أو الكرة

- أشيب المغذية سعر التكلفة

- فوجيياما كسارة فكية بي س

- أفضل المعدات محطم في عالم

- 100 الهيدروكربونات النفطية محطة كسارة الحجر

- آلة غسل الذهب من الصخور

- كسارة الفك مستعملة للبيع الجزائر

- مطحنة طحن الفك

- سرعة متوسطة تفتيش طاحونة ساعة

- الحزام الناقل جودة

- Flow Sheet Drawing Stone Crusher Plan Pdf

- Automatic Roller Mill Manufacturer From China

- Stone Crushing Industry In Tamilnadu

- Machines To Screen Sand In Bunkers

- Phosphate Rocks Crusher

- Calcium Carbonate Powder Grinding Machine In Sao Tome And Principe

- Quarries That Available For Sell In Nigeria

- Abene Milling Machine Electric Diagram

- Sme Mineral Processing Handbook Volume 1 For Sale

- Maize Milling Machines For Sale In Nigeria

- Rumus Tegangan Crushing Crushing

- Dust Collectors Ball Mill

- Industrial Gold Trommels For Sale

- Crush Stone Equipment Manufacturers

- Us Stone Crusher Equipment Company