Coal Mine Rom Washing

New report evaluates reserves, plans for New Elk coal mine ...

Jul 10, 2012 · All runofmine (ROM) coal produced will require washing for market. NECC anticipates washing the coal between a and specific gravity (SG) float, depending upon market requirements and the tradeoff between pricing and plant yield, the Agapito study noted.

Where our coal comes from

Oct 09, 2020 · The two largest coal mines in the United States are the North Antelope Rochelle and Black Thunder mines in Wyoming. Together, the two mines produced 22% of total coal production in 2019. The North Antelope Rochelle mine alone produced more coal in 2019 than the combined total coal production of Illinois and Kentucky, the fourth and fifth ...

Beneficiation

Beneficiation. This stage of production the run of mine (ROM) is made into clean, graded and consistent coal products suitable for the market. The process is completed after the material has been subjected to various stages Handling and Conveyance, Crushing, Screening, Washing and Grading. The beneficiation of ROM is conducted through a ...

Isaac Plains Coal Mine: Achieving record throughput rates ...

The open cut mine deposits provide the plant with a combination of metallurgical and thermal coal for processing. In 2008, our team was engaged to take on full responsibility of the Coal Handling and Preparation Plant (CHPP) operation, from Run Of Mine (ROM) to train loadout.

Semirara Mining and Power Corporation

ROM or Run of Mine Coal is the raw coal that is mined out of the mine pit. About 80% is Clean Coal and the remaining 20% is Washable Coal. Washable Coal is washed in the Coal Washing Plant to get rid of contaminants, with a 60% average recovery. The combination of Washed Coal and Clean Coal becomes the Total Product Coal or TPC.

About

The Run of Mine (ROM) coal is initially fed into a multi stage crushing and screening plant and delivered to a surge bin for beneficiating. The ROM is classified on a vibratory sizing screen, 50mm x 8mm, 8mm x 1mm and 1mm x 0 mm for specific metallurgical upgrading.

Middelburg Mine Services, South Africa

Oct 29, 1999 · Rom coal is processed in a heavymedium washing plant consisting of Wernco drums, cyclones and fine coal screen and solid bowl centrifuges. .

Coal preparation plant process and equipment for coal washing

Mar 27, 2019 · Coal washing is an industrial process in which impurities in raw coal are removed or highquality coal and inferior coal are classified. Coal preparation process Coal wash processing, meteorite processing, material and equipment transportation constitute the mine ground system.

(PDF) An efficient process for recovery of fine coal from ...

An efficient process for recovery of fine coal from tailings of coal washing plants. ... to also rec ov er v ery fine coal f rom fine coal taili ... —A Mine. Sca le Machine. Red ruth, Co ...

Mongolia making most of Chinese met coal demand

Sep 06, 2017 · In the first half of 2017, the company mined about mt of ROM coal and sold about mt of washed hard coking coal. Australian listed Mongolian coking coal miner, TerraCom, has also ramped up production this year after securing a mt hard coking coal supply contract over years with the Kingho Group, one of China's largest private ...

Mining Weekly

Sep 17, 2021 · The Bekezela colliery will be an opencast mine, with a target production of 600 000 t/m of runofmine (RoM) ore once in steadystate production, with a scheduled LoM of 19 years and the mine .

Mining Weekly

· Coal beneficiation provides substantial economic benefits for mines, as coal can be upgraded to be included as a saleable product that repositions the mines along the cost curve. The coal washing ...

CNB

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solidliquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solidliquid separation .

Management of coal processing wastes: studies on an ...

· Management of coal mining and coal processing wastes, particularly of high sulfur coals, can generate excessive amounts of sulfate (SO 4 2−) and chloride (Cl −) in mine drainage that are known to negatively impact quality of both surface and ground Environmental Protection Agency provides guidance to states on allowable SO 4 2− and Cl − discharges from mine sites.

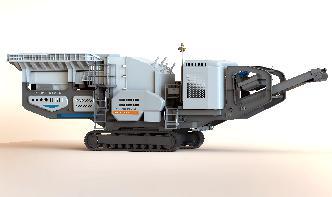

coal mine rom washing

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded . The coal delivered from the mine that reports to the coal preparation plant is called runofmine, or ROM, coal. This is the raw material . engaging tools. ROM coal can .

Coal Mine | Thiess Mining Projects | Thiess

The alliance was further extended in 2003 for the life of the mine. As the sole contractor operating on site, Thiess Indonesia provides totalmine solutions from mine and waste planning, clearing, overburden removal, coal crushing and washing right through to site environmental rehabilitation.

Masama coal mine approaches steadystate production

Aug 27, 2019 · According to the mine plans, from August this year it is envisaged that Minergy will be mining 110 000 tons run of mine (ROM) per month. The same quantities will be put through the washing plant and this should result in saleable coal of between 70 000 to 80 000 tons, increasing to 100 000 tons per month next year.

Latest Posts

- واستكمال محطة لتعدين الذهب في المملكة العربية السعودية

- اسعار الكسارات الحجريه فى مصر

- لا مثيل لها من كسارة الفحم

- آلة طحن الدولوميت للاستخدام

- غسل الرمال الأردن

- أفغانستان شراء حزام سير

- تخطيط مصنع تجهيز حجر الجرانيت

- خط إنتاج تكسير الطين في ألمانيا

- مصنع الكلي المحمول للبيع

- كسارة مخروطية متنقلة للبيع

- سعر كسارة متنقلة من الحجر الجيري في السودان

- استخدامات مطحنة عمودية lm

- محطم المحمولة للبيع

- تقرير عن مشروع سحق الكوارتز في مصر للحصول على قرض مصرفي

- 160 الموردين الهيدروكربونات النفطية قدرة كسارة في العالم

- Tct Blade Sharpening Machines

- Stone Crusher Machinery Second Hand

- Stone Crusher Plant Tph Stage

- Jaw Crusher For Sale In Harare

- Stone Crusher And Quarry Plant In Malaysia

- 5048 Horizontal Shaft Impact Crusher For Sale

- Profile Core Pin Grinding Methods

- Mining Mining Equipment For Sale In Chandrapur

- How Does Sand Making Machine Work

- Hand Cranked Rolling Mill Machinery

- Precipitated Light Calcium Carbonate Cacofor Industrial

- Equipment For Mining Industry

- Upcoming Cement Plant In Andhra Pradesh

- Helix Calculations For A Screw Conveyor

- Design Raymond Roller Mill