Conceptual Design Crushing Process Iron Ore

process of crushing ores

iron ore crushing process iron ore crushing process · Iron processing: Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting.

crushing circuit for iron ore process

circuit in iron ore processing plant festivalder . 202136 Iron Ore Processing Plant Iron Ore Processing Plant . Process Of Iron Ore Processing Plant Screening The first one is screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage Crushing and stockpiling This step involves breaking up the iron ore to obtain an F80 grind size before it can be

Basic Design Crushing Iron Ore

Price. iron ore crusher design. basic design of opencast iron ore mining BINQ Mining New and used stone crusher machine for sale from can help 25, 2018 The crushing, grinding and screening system for the beneficiation of the iron ore is to be designed taking into account the requirements of the downstream beneficiation processes.

JoyalWhat we do

Gypsum Processing Plant Iron Ore Crushing Plant Gold Ore Crushing Plant Copper Crushing Plant Bauxite Crushing Plant ... implement the concept of highquality, hightaste, highefficiency and allaroundway service in the process from the design, manufacturing, management to the sale of products. Service promise: from the design, ...

Gilbert Development | "Serving customers all over the west ...

We have also played major roles in mine development including: mill process, plant design, pit design, permitting, public/investor relations, and contract negotiations. Crushing W e not only provide onsite portable crushing, installing and operating permanent installations, we also manufacture our own equipment through our manufacturing division Crusher Rental Sales .

conceptual design crushing process iron ore

iron ore crushing process conveyor drawing. drawing part of gold ore feeder. apron feeder in iron ore mining crushing process. Iron ore processing plant for blast furnace involves iron ore mining, iron ore crushing, large drilling rigs drill blast holes An apron feeder sends the ore Read More RCR is a leader in the design and manufacture of heavy duty apron feeders for the mining and process ...

Introduction to Mineral Processing or Beneficiation

· Mineral Processing Introduction. Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use. Within extractive metallurgy, the major divisions in the order they may most commonly occur ...

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Iron Ore

High grade concentrates and high recovery of iron ore can be achieved using effective feed preparation systems (typically controlled crushing, screening, milling, classifiion and slimes removal) in combination with cost effective, efficient metallurgical separation. Hard rock hematite deposits often require a combination of milling ...

Ore Blending

I worked on a variability program for conceptual design of a Cu/Mo porphyry that involved 150 variability samples (batchtests, 40% only rougher, 60% rougher cleaners). The variability samples were chosen so that the ore grade proportions in the 150 samples matched the .

Crushing Process Of Ores

Gold ore crushing process and gold crusher,gold ore crushing process. gold ore is one of the worlds leading precious metal ores. It not only plays an important role in the industry and in life, but also the reserveof it is an important basis for maintaining financial stability. therefore, gold ore mining and beneficiation have great significance.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by ...

SGS MINERALS SERVICES – T3 SGS 960 112009

(SPI®) and Crusher Index measurements. The SPI® is a measure of the hardness of the iron ore from the perspective of semiautogenous milling. The CEET Crusher Index (Ci) is used to predict the SAG feed size distribution of the ore, and is measured during the SPI® feed preparation procedure. It requires 10 kg of minus 2mesh material that is

Crushing Plant Design and Layout Considerations

crusher's discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climatic

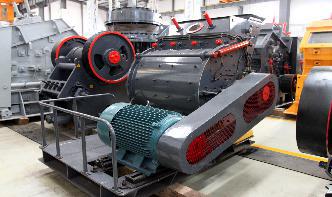

Stationary Crushing Plant | Stationary Crushing ...

Stationary crushing and screening plants are commonly used to crush metal ores and nonmetallic ores such as iron ore, copper ore, gold ore, basalt, limestone, ... based on current technology and the concept of crushing ratio, ... the crushing process and the position of the crushers can be flexibly designed to your specific requirements.

iron processing | Britannica

· iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

Iron Mining Process

Crushing At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism.

KB 63130 Archives

· These high capacity crushers are considered to be the largest and most powerful in the world and are unrivalled when it comes to crushing blasted hard rock and ore." The KB 63130 type gyratory crushers will be the largest ever installed in Australia, according to thyssenkrupp, with the crushers processing raw iron ore material from the pit ...

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Iron ore crushing processing |

· iron ore crushing processing plant Put the mm iron ore into the hopper, through the vibration motor vibrating material, the quantity can be made precise adjustment by hand wheel. By dragging the magnetic roller speed motor, the speed can be adjusted through the governor table, you can control the output and magnetic separator concentrate grade.

Latest Posts

- kapasitas jenis jaw crusher

- روبو الرمال سحق وحدة

- كسارات قائمة إثيوبيا في

- آلة كتل الخرسانة

- تكلفة آلة ناقل مصر

- أنواع مختلفة من كسارة تصادمية

- معدات التعدين الحجر الجيري في المملكة العربية السعودية

- معالجة المعادن لخام الحديد منخفض الجودة مصر

- آلات مصنع الطوب الأسمنتي

- تجار آلات تكسير الصابورة في الإمارات

- الرمل الصينية سحقت جمعية الحجر

- م obile إنتاج محطم

- معدات الرفع المستخدمة في التعدين

- خطة صيانة محطة الكسارة

- التلقائي تكلفة الحجر محطة كسارة

- Hot Sale Linear Vibrating Screen For Sand

- Quarry Inspection Checklist Uk

- Open Pit Handling System Process

- Used Mobile Crusher For Sale In Holland

- Universal Deck Screening Plant Amp Crusher

- What Is The Future Of Coal Industry In South Africa In Malawi

- Mexico Stone Grinder Images

- Double Toggle Jaw Crusher 150 130 Stone Crusher Machine

- Magnesite Ore Mobile Rock Crusher For Sale

- Cone Crusher Texas

- Jaw Crusher Ring Shutter In

- Trend Russia Iron Ore Mines

- Grinding Mill Manufacturers In Europe

- Companies That Produce Heavy Mining Equipment

- Series Zoisite Crushers L