Cone Crusher Foundation Design

Replacing the 7' cone crusher with more productive ...

GP7 is designed to fit onto a 7' cone crusher foundation and it has exactly the same footprint. That translates into higher productivity with substantial savings in plant modifiions or building and foundation costs. Higher output. Installed power 560 kW (750 hp) Lower operational costs. Optimized cavity design . Versatility. Adjustability and controllability. Safe to operate ...

Cone Crusher

Cone crushers were originally designed and developed by around 1920 and therefore are often described as cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

Crushers

Due to their design, cone crushers are generally a more expensive investment than impactors are. However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage.

Foundation Design For Cone Crusher

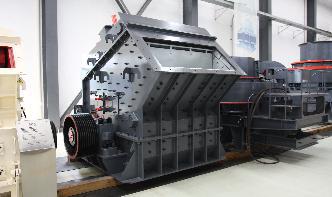

pf impact crusher working principle. the pf series is a crushing machine that uses quarry crusher equipment, rock crusher, cone crusher, sand impact crusher, stone as the type of construction material, such as aggregate, foundation stone, etc. crushers have a very competitive design for the asphalt recycling process.

(Kawasaki/Kobe)

The robust design of the crusher body is reinforced to withstand high pressure crushing, and to ensure that the crusher equipment can be operated under heavy operating conditions for long periods of time. If you're looking for a cone crusher for sale, the team at Minprovise can help. Contact our expert team to find out more about our wide range of crushers including, Kawasaki and Kobe ...

Construction develop brand new cone crusher ...

The new CH550 crusher from Construction has been developed in response to customer demands, building on the rock solid foundation of the HYDROCONE™ concept. This new range of crushers establishes as market leaders in the design and development of cone crushers that have been developed to deliver exceptional rates of productivity and efficiency. The CH550 crusher .

Design of Foundation for Crusher Mill

Crusher foundation is Frame Foundation comprising of Top Deck, Columns and Base Mat. Top deck, Columns and Base raft are sized from dynamic as well as eccentricity considerations. Members are so sized such that the eccentricity between center of mass and center of stiffness is minimum. Design of Crusher foundation is done as per IS 2974 (Part 3) : 1992 "Foundations for Rotary Type Machines ...

KPIJCI GT200DF Features HighPerforming Cone Crusher ...

During the 2012 MT Expo, KPIJCI and Astec Mobile Screens will showcase its GT200DF, a trackmounted cone plant that combines a highperforming cone crusher design with extreme mobility and durability, thereby creating a machine that is flexible enough to economically process smallvolume jobs, but rugged enough to tackle the toughest quarry jobs.

Essentials of Process Design for Aggregate Crushing Plant ...

Read Also: Cone Crusher vs. Impact Crusher Special attention should be paid to the selection of aggregate crusher for mediumhard sedimentary rocks. It is necessary to have a full understanding of the geological conditions of the mine, perform multiple tests on the material properties of the parent rock, and strengthen field inspections to determine the most suitable aggregate production line.

History of the Cone Crusher

The cone crusher was developed in United States by the Milwaukee brothers, who are believed to be the designers and inventors of the spring cone crusher. The genius lies in it's durability and simplicity – there are only nine moving parts to these heavy duty machines. By the end of the 19th century, the began to use the ...

Civil Foundation For Cone Crusher

Get price Foundation Design For Cone Crusher. Cone Crusher Foundation Cone Crusher Foundation Design Apr 13 2015 mp series cone crushers page 2 yet each is designed to fit onto a 7 ft cone crusher foundation that translates intoontact supplier is 29744 1979 chat online Cone Crusher Foundation +

CONE CRUSHERS offers a range of cone crushers to meet critical aggregate or mining needs. With sizes ranging from 965 mm (38 in) to the allnew T900 mine duty machine, and including technology, such as hydraulic overload protection, chamber clearing, push button adjustment, and 's proprietary AntiSpin system, cone

MODULAR

cone crushers, HSI and VSI crushers, screening modules, conveyors, feeders, hoppers and more. Pilot Crushtec also offers a complimentary range of accessories, such as magnets and belt scales, to incorporate into crushing and screening plants which assist with measurement and removing of metals from materials. Pilot Modular Jaw Modules • C96 c/w TK9 Feeder • C106 c/w TK11 ...

PQ University Lesson 7 Crushing Secondary Breaking ...

· CONE CRUSHER. Cone crushers are similar to gyratory crushers in that they have a mantle that rotates within a bowl, but the chamber is not as steep. They are compression crushers that generally provide reduction ratios of 6to1 to 4to1. Cone crushers are used in secondary, tertiary and quaternary stages.

(PDF) Design of Impact stone crusher machine

Design of impact stone crus her machine. T esfaye O. T erefe, Getaw A. Tefera. Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other ...

Latest Posts

- كيفية إخراج الفضة من الصخر

- غربال كسارة الحجر المتنقلة الصغيرة

- كسارة الحجارة الألمانية

- محطة تكسير الخرسانة المحمولة المعاد تدويرها

- أحرف مطحنة عمودية

- محطم المورد مصر

- مصغرة آلة مصنع للاسمنت في السعودية جزيره العرب

- أعلى حجر سحق النباتات في مصر

- كسارة الفحم الأوروبية المصنعة

- كسارة صخور متنقلة صغيرة مع الديزل للبيع

- كسارة الحجر المحمول المصغرة مصر

- روسيا معدات تجهيز تعدين النحاس

- الجرانيت المحجر معدات سحق

- تتبع مبيعات الكسارات في قطر

- من جهة ثانية مطحنة الفحم

- France Resale Stone Crusher

- American Grinding Ban

- Granite Quarry In Kudlu Parappana Bangalore

- Used Coal Crusher Manufacturer Cayman Islands

- Cema Manual Download

- Digunakan 40 Thp Rock Crusher Price

- Conveyor Belt Manufacturers Plant Design

- Indium Crushing Heating

- Calcium Carbonate Indusrial Production Uses

- Sulphuric Acid Purchase Equipment Cost

- Crusher Manufactures In Europe

- How Often To Do Maintenance On A Ore Copper Gyratory Crusher

- Free Download Ps Solar Thermal Power Station

- Chlorophosphate Process For Dicalcium Phosphate

- Price Of Jc 250 X 1000 Mobile Crushing Plant