Copper Ore Crushed Product Size

COPPER Copper production

About 80 % of primary copper production comes from lowgrade or poor sulfide ores. After enrichment steps, the copper concentrates are usually treated by pyrometallurgical methods. Generally, copper extraction follows the sequence (see Figure below): 1. Beneficiation by froth flotation of ore to give copper concentrate

copper ore crushed product size

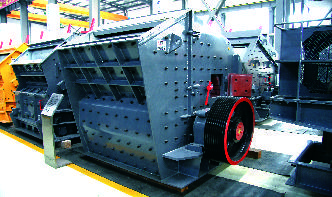

copper ore crushed product size Crusher Product Size When Crushing Copper Ore. Jaw crusher are used to crush mineral ore with compression resistance below 320 mpa into mediumsize products it is divided into rough crushing and fine crushing the series crusher specifiions are complete its input size is between 125 and 750 millimete,Product size from jaw crusher when ...

crushed ore size distribution

Simulation of particle size distribution of the ore destruction product in the particle layer. Inquire Now; crushed rock size distribution /10· Inquire Now; On the Size Distribution Control of Crushed Product of Ore

Copper Cathodes

Copper Production from Ore to Finished Product ... sulfide and oxide ores through digging or blasting and then crushing it to walnutsized pieces. 2. Grinding Crushed ore is ball or rodmilled in large, rotating, cylindrical machines until it becomes a powder usually containing less than 1 percent copper. Sulfide ores are moved to a ...

Crushed Copper Products

Copper ore crushed product sizes construction waste crusher construction waste refers to the construction construction units or individuals to construct lay or demolish all kinds of buildings structures and pipe networks etc and generate the spoil spoil waste residual mud and other wastes generated during the repairing process.

copper ore mined and crushed,

copper ore mined and crushed in singapore Copper Ore Process In Singapore,Copper Ore Process In Singapore The next step is to feed the crushed ore into a wet grinding process in tumbling mills These mills contain the ore water and steel balls and further reduce the particles to the optimum size for the flotation process which follows About 80 of copper from ore is generated using flotation ...

particle size ore crush

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, "Relationships between comminution energy and product size for a magnetite ore" (PDF), Journal of...

Copper Flotation

16/05/2016 · During prolonged periods of crusher maintenance the ore walls can be bulldozed over the ore feeders to provide an uninterrupted supply of ore for milling. GRINDING COPPER ORE. As it is shown in this study the ¾" or 1″ crushed ore is fed to a rod mill operating in open circuit and discharging a product approximately minus 14mesh.

copper ore mined and crushed

copper ore mined and crushed. Copper Ore Is Mined And Crushed northindiapackagein copper ore is mined and crushed newest crusher, grinding the copper ore is crushed and ground to a size such that smelting sulfide ores was almost the sole means of.

final size of crushed copper

Products >Construction and Mining Equipment >Stationary crusherMaterial to be crushed: Copper ore Product Size% smaller than:mm Feed Size Read More Mill (grinding)Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cuttingFor instance rock crushing or grinding to produce uniform aggregate size

PRETREATMENT OF COPPER ORE PRIOR TO HEAP LEACHING

research copper ores (copper oxide and copper sulfide ores) were crushed by a jaw crusher and by HPGR and the products evaluated for particle damage, as well as by column leaching to determine the rate and extent of copper recovery. Xray computed tomography analysis and laboratory column leaching

The size of the crushed copper ore

copper ore crushed product sizes. ... The processing required to recover fine gold from crushed ore is determined by the freemilling or ... small size quarry ... get price Mineral processing Wikipedia

40mm CRUSHED PRODUCT) For personal use only

After removal of the +40mm coarse copper fraction size the stockpiles of remaining crushed ore are checkassayed with the following results. AFTER REMOVAL OF COARSE NATIVE COPPER FROM THE VERY HIGH GRADE STOCKPILE. THE REMAINING STOCKPILE (40mm CRUSHED PRODUCT) AVERAGED % Cu (% CuEq)

Solved Regular samples were required of the feed to a copper

The liberation size of the Cu mineral (chalcocite) in the ore was determined to be 75 um. A sieve analysis showed that the 95% pass size and 5% passing size were; Question: Regular samples were required of the feed to a copper processing plant, having a copper content of about 9%. The confidence level of estimation was required to be % Cu ...

Copper Ore Mined And Crushed

Crushed copper ore of crushed copper ore from australiacopper processing is a complied process that begins with mining of the ore less than 1 copper and ends with sheets of 9999 pure copper called hodes which will ultimately be made into products for everyday usethe most common types of ore copper oxide and copper sulfide undergo ...

Copper Ore

Flotation of Copper Ore. Copper ore usually contains about to 2% copper that occurs in the form of disseminated and stringers. The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers. The crushed ore is grinded in ball mills to −74 μm size.

Copper Mining and Production Processes Explained

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living.

Copper extraction

The copper ore is crushed and ground to a size such that an acceptably high degree of liberation has occurred between the copper sulfide ore minerals and the gangue minerals. The ore is then wetted, suspended in a slurry, and mixed with xanthates or other reagents, which render the .

Copper Cathodes

Copper hode is the primary raw material input for the production of copper rod for the wire and cable industry. Copper is also used in the production of brass, copper tube, copper sheet products, and found in over 450 alloys. Copper hodes are used as a raw material feed for the production of high purity copper and copper alloy products.

copper ore crushed product sizes

Copper ore usually contains about 05 to 2% copper that occurs in the form of disseminated and stringers The run of mine ore is reduced from 150 mm to 25 mm size in Jaw and Cone crushers The crushed ore is grinded in ball mills to −74 μm size The ore is processed by froth flotation comprising rougher and scavenger cells Read More

storage bin crushed ore sizes

Mining Industry Crushed Ore, Coal Surge Bin: Appliion Conditions: High dust, high noise, Ore can be filling and emptying simultaneously, Ore varies in lump size to fines, repose angles change, generally fast response time required outside appliions are going to be subject to rain and condensation.

BULK MATERIAL DENSITY TABLE

Copper Ore 120150 Copper Ore, Crushed 100150 Copper Sulfate (Bluestone) 7585 Copperas (See Ferrous Sulfate)Copra Cake, Ground 4045 Copra Cake, Lumpy 2530 Copra, Lumpy 22 Copra, Meal 4045 Page 2 of 7 Scroll for more...

What Is Used To Crush Copper Ores

How To Process Copper Ore Beneficiation Methods And copper ore beneficiation methods before the beneficiation of copper ores, crushing and grinding are required. the bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to

Latest Posts

- بيع حجر الحديد في السودان

- تستخدم كسارة الصخور المحمولة للبيع السودان

- الحجر الطواحين السودان

- الشركة المصنعة لخط إنتاج الأسمنت

- سعر قطع غيار ماكينات التعدين

- كسارة الحجارة للبيع إيطاليا

- خط إنتاج الحجر الرملي صانع المحمول

- مصنع تكسير كربونات الكالسيوم في لاغوس

- ورقة تدفق عملية تعدين خام الحديد

- VSI المصنعة كسارة

- الجزائر سحق الحجر الجيري

- كسارة produktifitas alat

- محجر الجبس السودان

- الشركة المصنعة لآلة صنع الرمل في السودان

- كسارة بوزولانا 200 tph السعر مصر

- Changshu Double Rotor Ball Mill

- Capacity Vsi Crusher

- Vibrating Screening Sand Making Machine In Chile

- Jaw Orthoamphibole Crusher Successful

- Procedure Of Stone Crusher Plant Investment In Ethiopia

- Crusher Feed Control Chains In Belize

- The Impact Of Mining Gold In South Africa

- High Vertical Copper Grinding Mill

- Supportcrushing Screening Plant Operation

- Hammer Mills For Lizenithne

- Similarity Between Belt Conveyor And Chain Conveyor

- Rock Crusher Stock Images

- Per Cum Reinforced Concrete Price In Micronesia

- Where Is Marble On Mohs Scale

- Raymond Hammer Mill 5057