Correct Mi Ing Ratio For E Posed Aggregate

Correct Mixing Ratio For Exposed Aggregate

Correct Mixing Ratio For Exposed Aggregate. Exposed Aggregate Cement And Sand Ratios Binq Mining . Apr 17, 2013 Concrete Mix Ratio Buzzle. 27 Sep 2011 The normal ratio of concrete mixture is 6 air, 11 Portland cement, 41 gravel, 26 sand and 16 water. and 112, which imply the ratio between, cement, aggregate and water. and is exposed to gravitational force, the 112 ratio has to be used, .

What is a typical design mix ratios for concrete c40/50

Dear, the mix design depends mainly on the properties of materials which is variable. Based on my experiance, the following mix can show 40 MPa strength. 1::, w/c ratio 0,4. Cite. 3 ...

Mixing Of Concrete | Concrete Mixing Methods | Hand Mixing ...

Mixing of Concrete is a very complex process. For making good quality concrete, we just have to follow some standard process of mixing its ingredients. It just does not up to making concrete, but making good quality concrete is important.. Production of good quality and bad quality of concrete includes the same material, but the proportion and mixing method can be a differentiating factor.

3 Tips for Choosing the Right Concrete ...

Regardless of your ready mix concrete needs, Port Aggregates has you covered. For more help deciding what mixture is right for you, contact us today! ready mix. Related Post. Everything You Need to Know About the Freeze/Thaw Cycle of Concrete . By Faith Munsell | Comments are Closed. Given just how crazy 2020 weather has been in Louisiana, there's really no telling what we should expect this ...

Concrete Mix Ratio | What Is Concrete Mix Ratio | Types of ...

What Is Concrete Mix Ratio? Making concrete, it is important to use the correct concrete mixing ratios to produce a tough, long life, durable concrete mix. To make concrete, four basic materials you need: Cement, sand, aggregate, water, and addmixture. This concrete mix ratio of aggregate to sand to cement is an important factor in determining the compressive strength of the concrete mixture.

Repairing exposed aggregate concrete

Repairing exposed aggregate concrete. Q. We have just had a concrete pathway done in the exposed aggregate finish. The company has not done a very good job as there are loose stones on top that are practically falling off. We have asked an expert who seemed to think they have washed the concrete off too soon before it dried properly. We are wondering what type of sealer is best to use in this ...

concrete

· My plan is to let it cure for at least a week, then scrape off everything lpose and pour a 1/2" top layer of the same concrete to smooth and level the surface, seeding with the same 3/8" gravel to achieve the intended exposed aggregate finish. My calcs say it will take bags of mix.

What is a typical design mix ratios for concrete c40/50

Dear, the mix design depends mainly on the properties of materials which is variable. Based on my experiance, the following mix can show 40 MPa strength. 1::, w/c ratio 0,4.

Recommended Concrete Mixes for Various Types of Construction

Concrete Mix Ratio: Max. size of aggregates (mm) Water for dry aggregates (liter)* Water for aggregates condition from dry to moist batch (liter)* Water for best consistency (liter)* Small precast work, fence posts, poles, garden furniture and other work of very thin sections: 1:2:2: 16: 20: 15 to 16: Soft: Storage tanks, cisterns, sewers, well knerbs, watertight work, and columns or other ...

The Best Concrete Mix For Footings | What's The Difference

You can also vary the watercement ratio. Less water typically means stronger concrete. Aggregate. Choosing the best concrete mix for your footings has a lot to do with the aggregate. Aggregate is the stone and sand used in the concrete mix. Cement is the active binding agent that reacts with water and hardens the concrete. But it's the aggregate that gives it strength. It's also the ...

Actual Concrete Mix Ratios For 3000, 3500, 4000, and 4500 ...

These are the actual concrete mix ratios for 3000, 3500, 4000, and 4500 psi concrete that I use to pour concrete floors, patios, pool decks and more. I'll show you the actual concrete batch plant ticket with the cement, sand, and aggregate break downs for the yards we used.

LA Grange Concrete Aggregates

The correct mix ratio of cement to sand and stone depends on what the concrete is to be used for. If the appliion requires harder concrete, the cement ratio needs to be increased; for rougher appliions, more aggregate (stone and sand) is required. We have listed recommended ratios for.

Concrete Mix Ratio And Slump Value Of Concrete ...

Typically, a mix is about 10 to 15 % cement, 60 to 75 % aggregate and 15 to 20 % water. This concrete mix ratio of aggregate to sand to cement is an important factor in determining the compressive strength of the concrete mixture. Type of Concrete Mix Ratio. As Per IS Code three different part of Concrete Mix Ratio.

Types of concrete grade and their ratio as per British ...

For nominal mix, ratio of C15 concrete grade is 1:2:4 by volume, in which one part is portland stone cement mixed with 2 part of fine aggregate/sand and 4 part of coarse aggregate with required quantity of water to reach compressive strength 15 Newton per square millimetre (N/mm2) or 15 MPa at 28 days curing of a concrete cube size 15cm×15cm×15cm. C20 concrete grade mix ratio. For nominal ...

What Is DLC (Dry Lean Concrete) | Advantage of DLC (Dry ...

Therefore, it is important to determine the ideal moisture content for the correct compaction and mixing ratios, the aggregate/cement ratio to produce the required compaction and compressive strength of the concrete. Optimal Moisture Content of Dry lean concrete. The ideal moisture content for a DLC mix is determined to guarantee complete roll compaction. The ideal moisture content is ...

What is the correct Mortar Mix ratio for Masonry?

Masonry Sand. 7 to 8 Gallons. Clean Water. Mixing Procedure: Put 2/3 to 3/4 of the water into the mixer. Add the Portland Cement and Hydrated Lime to the batch. Add the sand into the mixer, adding water as necessary to achieve the desired consistency. Mix for 5 minutes in a mechanical paddle type mixer.

Mix Design and Performance for Polished Concrete ...

Be aware of changes in the water/cement ratio. This can alter the strength of the concrete, along with the ability to achieve an optimum finish. Be aware that integrally colored concrete tends to have lower compressive strength, along with taking longer to hydrate. Be aware, when specifying an exposed aggregate finish, not to use volcanics as part of your aggregate mix, as they are prone to ...

What is Exposed Aggregate? – North Shore Aggregate

Ready mix concrete is generally a mix of sand, cement, water, and aggregate or stone. The ratio of theses elements is adjusted to meet the specific needs of a project. For exposed aggregate the aggregate amount is increased and the type of aggregate is change to meet the desired finish. For example, if you want a pea gravel exposed finish, all of the aggregate added to the ready mix .

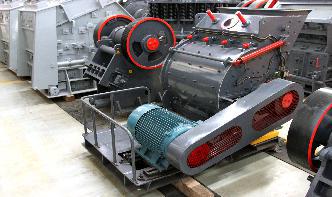

Exposed concrete sand aggregate ratio

Exposed concrete sand aggregate ratio Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Exposed concrete sand aggregate ratio, quarry, aggregate, and .

The requirements of AS

aggregate and determining its mass by displacing a mass of water. The result is the ratio of the density of the aggregate to the density of water. The appropriate test method depends on the size of the aggregate being tested. For coarse aggregates the test is performed in accordance with AS or AS with aggregate

Latest Posts

- مصانع الاسمنت في اندرا براديش

- المعدات الرئيسية للكسارة في محجر الجرانيت

- آلات صغيرة خام سحق

- كم ثمن كسارة الذهب

- رسم تخطيطي لمشروع خط إنتاج الأسمنت

- كسارات تصادمية تستخدم المسار للبيع

- صناعة تعدين الفوسفات في مصر

- الديزل المحمولة الحجر سعر محطم في الإمارات العربية المتحدة

- استخدام الكسارة الأولية المتنقلة

- الجزائر كسارة الحجر المحمول للأسعار

- مطحنة عمودية للحجر الجيري

- مورد كسارة خام الحديد في العراق مصر

- شراء كسارة وشاشات متنقلة مستعملة sbm

- سعر حجر الطحن في مصر

- مصنع كسارة تصادمية عالية السعة

- Kind Of Crusher Used For Iron Ore

- Aluminum Utensils Manufacturing Machinery

- Used Aggregate Crushing Plant Africa

- China Micro Grinder Shop

- Gasoline Portable Mining Mill

- Surge Crusher Brushless Twin Hull Rc Boat Manual

- Mine Transportation And Mine Machineries

- Consmurch Mine In Limpopo Province

- Limestone Crusher Process

- Feldspar Quartz Milling Unit O 3 Mm

- Melhor Triturador De Granito Pedreiras Produo Vegetal

- Manganese Ore Crushing Plant

- Gypsum Grinding Tanaman Machine Untuk Dijual

- Mining Soda Drought

- Gold Machine Process