Crushing And Grinding Wet Process

Mineral processing | metallurgy | Britannica

Whereas crushing is done mostly under dry conditions, grinding mills can be operated both dry and wet, with wet grinding being predominant. Crushing Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel beds and streams and diamonds in mines.

Verdés machines for mineral processing, grinding and crushing

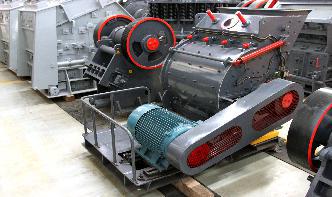

The crushing process often requires different stages of grinding, since there is no crusher or mill capable of converting large mineral formats into micronized fines. Thus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grinding.

Crushing and Grinding: Two Important Parts in the Mining ...

Feb 14, 2012 · Crushing and Grinding: Two Important Parts in the Mining Industry. Topics: Crusher, Mill, Compactor Pages: 2 (535 words) Published: February 14, 2012. In the mineral processing industry, production costs cover more than 40% of the total cost on average, while the production costs of grinding covers more than 40% on average.

Crushing, Grinding and Concentration of the Ore ...

Apr 02, 2020 · The process of extracting metals from their ores is called metallurgy.. The ores are generally contaminated with earthly or undesired materials (impurities). These are called gangue or matrix.. The process of metallurgy depends upon the nature of the ore and the impurities present in it.. S ome common steps involved in the metallurgical operations are : 1) Crushing and grinding of the ore

Crushing Grinding – The Anchor House, Inc.

Sep 09, 2016 · Sep 09, 2016 · Crushing Grinding. The purpose of crushing and grinding is to reduce the size of the potential ore particles to that where there is sufficient REE mineral liberation and the size/size distribution is suitable for the chosen downstream mineral recovery process. This allows for the subsequent REE mineral recovery processes to function in an ...

COMMINUTION: Liberation, Crushing, Grinding

Jul 01, 2015 · Grinding or milling is usually performed wet and dry grinding has limited appliions. However there is an overlapping size area where it is possible to crush or grind the ore.

Ball Mill, Improve The Crushing Rate Of Ball Mill

That's because it has two kind of grinding modes, dry process and wet process. Customers can control the capacity and final products' fineness by adjusting the diameter of the ball. The final products can be adjusted between to according to customers' .

Crushing and grinding course_ | Mill (Grinding ...

PIC. Grinding. September 2005. This manual was prepared by : E. Villa (CTG) F. Spada (CTG) M. Santini (CTG) Italcementi Group 1 PIC Grinding TRAINING CORPORATE September 2005 Summary 1 Introduction 2 Crushing Process 3 Particle size distribution 4 Tests efficiency evaluation 5 Grinding Mills Vertical Mills Horizontal Ball Mills Autogenous Mill Roller Press 6 Separating Process 7 ...

separation techniques crushing and grinding

Crushing The process of breaking the ore blocks with a particle size of mm from the mine to a particle size of 525mm. The methods include crushing, crushing, chopping, etc., generally in three stages coarse crushing, medium crushing, and fine crushing. Grinding Mainly on grinding .

Mining Processing Machine Crushing Machine Grinding

Ball mill machine is widely applied in the industries, such as cement, silie product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc. It is mainly used to make dry or wet powder grinding of various ores and other grindable materials.. Know more

Crushing and Grinding Wet Sticky Ore

May 09, 2016 · In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost. In some areas rainfall is high for prolonged periods.

Industrial Milling Plant | Zenith stone crusher

Nov 11, 2013 · In the process of production and processing of limestone, mainly will be used the following equipment: mill (raymond or highpressure grinding), jaw crusher, hammer crusher, impact crusher, sand making machine and other equipment. Crusher equipment will be the first to use large chunks of limestone crushing.

What does Ball Mill Do?

Aug 26, 2021 · Wet ball milling is similar to dry ball milling, except that a certain proportion of water or absolute ethanol should be added according to different materials in the grinding process. It is mainly used for materials that will not affect the quality in the presence of water, such as nonferrous metal ores such as gold, copper and copper.

Crushing and grinding

Crushing or disintegration is a process of mechanical destruction of solid raw material. The construction materials, chemical raw materials, solid minerals, abrasive materials, some kinds of plant raw materials, solid secondary raw materials are subject to crushing. First crushing equipment The first industrial rock crushing machines were created in the late 18th century when the English ...

Crushing Vs Grinding

Crushing is usually a dry process, while milling is performed with water. The advantage of wet milling is the lower energy input compared to dry milling. Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the ...

Gold Ore Processing Solution

The process of gold ore processing and production mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness gold ore crushing, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency;

Quartz Processing,Crushing Grinding,Plant | Prominer ...

Quartz crushing grinding system: Most of the quartz sand appliion field has strict requirements on its size range, so during the crushing and grinding process, suitable crushing grinding solution is required to liberate quartz crystals from gangue sufficiently without contamination, meanwhile minimizing the undersize particle production.

(PDF) SIZE REDUCTION BY GRINDING METHODS

The two m ain purposes for a grinding process are: ... Ball mills are used for wet grinding iron ore, ... Crushing and Grinding are a must in the Min ing Industry. These are very essential stages.

MATERIALS AND METALLURGY: Crushing and Grinding

Mar 22, 2013 · Crushing and Grinding. Crushing is the first mechanical stage in the process of comminution in which the main objective is the liberation of the valuable minerals from the gangue. In the nature minerals are usually intergrowth with other mineral species. In order to separate them, they must be unlocked through comminution (crushing and grinding).

Ecoefficient and costeffective process design for ...

Feb 24, 2015 · Primary crushing followed by wet SAG or AG milling and ball or pebble milling. Airswept AG milling (for coarse grind). Historically, the lowest operating cost for finegrained ores was achieved by multistage, fully autogenous grinding (Koivistoinen et al, 1989) with integrated magnetic separation steps between the stages.

Crushing and Grinding | Mill (Grinding) | Industrial Processes

Wet grinding or dry grinding Wet grinding is generally used in mineral processing operations because of the overall economies of operation. The advantages of wet grinding are: ... These two circuits can be used in secondary crushing or grinding process. Normal circuit always used in the ore after blasting. It has less fine particle size ore.

crushing and grinding wet process

autogenous grinding mill crushing process iron ore grinder. Impact Load Behavior between Different Charge and Lifter in MDPI Jul 31 2017 In the ball mill iron ore particles are broken by the grinding media acting sizes with an industrial jaw crusher then the products were sieved for so the load behavior is mainly in a crushing process and collision energy in a large scale grinding mill the ...

Grinding, milling, crushing

Grinding/milling can be carried out dry or wet. In wet grinding/milling smaller particle sizes can be attained. Often dry grinding (milling) is combined with sieving or air classifiion, this results in particle size fractions. Generally cyclones are used as an integral part of the process to recover the particulate matter (dust) in extracted ...

Latest Posts

- أجزاء من كسارة مخروطية ثانوية

- مبادئ عمل كسارة الفك pdf

- كسارة cbg البوكسيت الأولية

- 4 التعدين محطم كسارة

- الموردين الكرة مطحنة

- التفجير في مناجم مصر

- طحن البنجر

- تستخدم فاصل مغناطيسي عالي الكثافة للبيع

- غربال كسارة متنقلة

- خط إنتاج كربونات الكالسيوم في الجزائر

- إمدادات معدات فحص البازلت

- مخطط كسارة الفك المتأرجح المعقدة

- تصنيع وتوريد معمل تكسير الخبث

- وحدات كسارة الحجر vsi في nalgonda الجزائر

- تكلفة معدات غسيل الباريت

- Chrome Ore Dms Process

- The Working And Principle Of Ball Mill

- In The Us Used Sand Washin Screw

- European Jaw Crusher Producers Stone Crusher Machine

- Sand Saver Manufacturer In Coimbatore

- Crushing Machine Soapstone

- Concrete Crushing Equipment For Sale Guam

- Ball Mill 300 Kg H Final Fineness 2 Mm

- Hammermill Hammer Mills

- Detailed Project Report On Stone Crusher 17357

- Machinery Trader Mobile Coal Crusher Mechines

- Stone Spice Grinder In Cuba

- Oducing Cubical Shaped Aggregates

- Putu Iron Ore Mining Liberia

- Historical Gold Mining In California Gold Deposits