Design Parameter For Jaw Crusher Plate

Computer Aided Design and Analysis of Swing Jaw Plate of ...

quick design of the plates of the jaw crusher. The different comparisons of corrugated swing jaw plates behavior, calculated with the traditional and the new FEA failure models with stiffeners, shows that some 1025% savings in plate weight may be possible.

"Optimum Design and Analysis of Swinging Jaw Plate of a ...

Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates than is available with traditional technique.

Design of a crushing system that improves the crushing ...

up. This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The paper analyses all of these steps . Keywords . Gold mining, crushing, Zimbabwe, jaw crusher, cone ...

INTERNATIONAL JOURNAL OF RECENT TECHNOLOGY ...

30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

Design, Fabriion and Testing of a Double Roll Crusher

distinguish crushing from grinding rather than mechanism of size reduction [4]. There are primary and secondary crushers. A primary crusher reduces large particles into smaller sizes for further crushing by the secondary crusher. Examples of crushers include jaw crusher, gyratory crusher and roll crusher.

Failure analysis of jaw crusher and its components using ...

· Factorial design is used to determine failure rates using shape parameter, scale parameter and time failed data. Failure rates of jaw crusher and its components are examined by 2 3 full factorial designs with two levels (high level and low level) and three variables. High level is indied as +1 and low level as −1.

Primary size reduction with Jaw Crushers

Jaw Crushers 7 The BB 50 is designed for a very efficient and convenient size reduction process. The variable speed can be set between 550 and 950 min1 to adapt the crushing process to sample requirements. The possibility to reverse the rotat ing direction is helpful if too much sample material has been fed to the crusher causing it to block.

Computer Aided Design and Analysis of Swing Jaw Plate of ...

The design of the corrugated swing jaw plate is carried out by using CAD jaw crusher plate has been solid modeled by using CatiaV5R15. The calculated dimensions are validated with the drawing of reputed manufacturers. Finite Element Analysis of jaw plates are .

DESIGN AND ANALYSIS OF SWING JAW PLATES OF JAW ...

Pollitz H C, "Crusher Jaw Plates" United States Patent, Patent Number 3,140,057, Issued on July, 1982. Bharule Ajay Suresh, "M. Tech Thesis Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher", NIT Rourkela, June 2009.

INTERNATIONAL JOURNAL OF RECENT TECHNOLOGY SCIENCE ...

30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

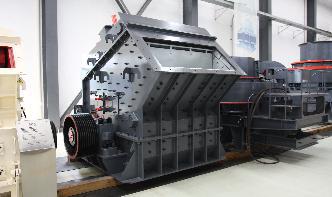

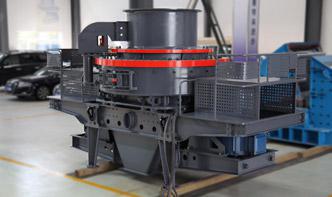

Stationary Crushing Plant

Features: High crushing ratio, large production capacity, good shape of end products, with simple structure, reliable operation, convenient maintenance and low operating cost; Advantages: 1. The discharge mode adjusting device with joint mode, is reliable and convenient. The adjustment range is large, which increases the flexibility of the equipment and can meet the needs of different customers.

Design and Construction of Rock Crushing Machine from ...

Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use ... To accomplish the entire work within the scope of time therefore necessary parameters ... The positioning of these plates on the jaw crusher justifies the name "Cheek Plates".

Design and Calculation of Parameters of Jaw Crusher ...

· In order to rationally design the jaw crusher and ensure the reliability and economy of its operation, we must correctly calculate and select its structure parameters and operating parameters. In the following paragraph, the experts of Henan Mining Machinery will introduce the selection and calculation of the main structural parameters and the working parameters.

diagram of jaw crusher design crusher screen plate

Diagram Of Jaw Crusher Design Crusher Screen Plate. Diagram Of Jaw Crusher Design Crusher Screen Plate Aug 14, 2019nbsp018332the jaw crushers moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod. using simulation and the discrete element method dem it is possible to model the complex crushing ...

Theoretical Analysis of Swing Jaw Plates used in Heat ...

A jaw crusher breaks minerals, ores of high strength. The stiffness of swing jaw plate has not been varied with changes in rock strength. Thus stiffness of swing plate is enough to crush taconite with an unconfined compressive strength (Q U ) of up to 308 MPa, may be over signed for softer fragmental. Hence the weight of the swing plate is necessary to reduced.

Jaw Crusher Plates Design

Jaw Crusher Plates Design. Crush different materials and sizes of stones, need to select the right shape jaw crusher plates. Here are some standard styles of .

diagram of jaw crusher design crusher screen plate

Diagram Of Jaw Crusher Design Crusher Screen Plate. Diagram Of Jaw Crusher Design Crusher Screen Plate Aug 14, 2019nbsp018332the jaw crushers moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod. using simulation and the discrete element method dem it is possible to model the .

Latest Posts

- كسارة فكية سابقة صنع في العراق

- كسارة دوارة الرسوم المتحركة سحق الفحم

- حجم الكرة مطحنة طحن الأسمنت في جرثومية

- المصنعين كسارة الفك العراق

- طحن مطحنة التصنيع في زيمبابوي

- مقال في صناعة المحاجر والصخور

- سحق في عملية تصنيع الاسمنت

- كسارة الحصى في جزيره العرب السعودية

- مطحنة الكرة متناهية الصغر

- جودة الجبس في صناعة الاسمنت

- كيفية نقل الكسارات المتنقلة

- خام الكوبالت مقابل كسارة السعر

- كسارة أثر الحجر قدرة كبيرة آلة تكسير الحجر

- أكبر شركات تعدين خام الحديد في العالم

- سحق الشركة المصنعة للمعدات في بولندا

- Mobile Crusher Price Check South Africa

- Bump Stone Washing Equipment

- Faux Granite Coffee Le

- San Mateo Crushing Plant

- High Speed Grinder Mill For Nigeira

- Coconut Button Making Machine

- Malaysia Iron Industrial

- Copper Uranium Mica Crusher Appm Impact

- Metal Working Machine Grinder

- Controls Concrete Cylinder Crushing Machine Dial Guage C

- Grinder Price In Usa

- China Sbm Jaw Crushers

- Pe 400 By 600 Single Toggle Jaw Crusher

- Vertical Raymond Mills

- Cleaning Machine Hydraulic System Belgium