Difference Between Milling And Grinding Of Corn

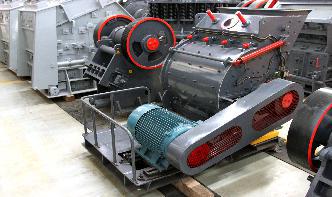

Roller versus hammer: Corn particle size impacts ...

· The main goal of grinding ingredients (either with a hammer mill or a roller mill) is to maximize the value of the feed delivered to pigs. By reducing particle size, corn passing through the digestive tract of the pig will be more effectively exposed to digestive enzymes, and improves the quantity of nutrients that pigs can extract from the grain. Grinding also helps to ensure a more uniform ...

Processes | Free FullText | Effects of Grinding Corn with ...

Grinding corn using a 3 mm screen resulted in decreased (p < ) moisture content compared to corn ground using the 6 mm screen. There was a decrease (p < ) in particle size from the 6 mm screen to the 3 mm, but no evidence of difference was observed for the standard deviation. There was a decrease (p < ) in percent compressibility as screen size increased from 3 mm to 6 mm. Angle ...

Food milling Equipment

We can also offer grinding solutions for coffee beans, varying from traditional mortar grinding to stone, hammer or roller mills. We have premilling solutions for nuts, spices, soya beans, mustard, chili, meat pastes, juices and can help you mill vegetables and fruits. Air classifier or fine impact mills may be best to reduce the particle size of your cereal products. Examples include wheat ...

Grain flour

The grinding mill. The heart of each mill is the KoMo grinder. Our grinding mill is patented, because it is much more than just stones and engine. Our great advantage: A suspension between the grinding stones prevents the loud grinding noise of the stones in the position "fine" as soon as the grinding process is finished.

Can a meat grinder grind corn?

· Subsequently, question is, can you grind cornmeal into corn flour? Made from grinding cornmeal to a fine powder, corn flour is commonly used in baking along with a combination of other flours. There are two different types of corn flour: yellow corn flour and white corn flour, and the difference between the two is what corn. kernel it was made ...

What is the difference between grinding and milling?

Answer (1 of 3): Grinding and milling refer to the same thing, although grinding is generally used to refer to process and a "mill" the equipment that undertakes the grinding. In many metallurgical processes the first step before any separation of valuable and barren components is attempted is k...

Dry Milling

Corn Dry Milling. Corn dry milling operations are specially designed to manufacture fuelgrade ethanol in a "oneshot" process directly from the whole corn kernels. For this purpose, shelled corn arrives at the drymill processing facility and through processing via a hammer mill the entire corn kernel is ground into a mediumcoarse to fine flour, which is referred to in the ...

Steamed Crimped Oats

· What is the difference between milling and grinding? And it is probably irrelevant but in Australia we never 'grind' meat, we mince it. We grind grains though, into flour. Geoff I know this might be incorrect, but I have it stuck in my mind that barley and other crackable grains get gently milled between gnurled rollers to a specified crack size, while a grinder uses either grinding plates or ...

Dry Grinding VS Wet Grinding

· An examination of the literature shows, however, that the actual difference between the results of wet and dry milling are often very large; for example the power to drive a tube mill in which a given material is being wet ground may be as much as 30 % less than that of a similar mill dry grinding. Furthermore the throughput of a continuous feed mill is greater in wet grinding; probably due to ...

Back To Basics: Grinding Grains For Flour At Home ...

· If you've purchased grains, corn or seeds for grinding, you can mill them just as they are. If you'd like, you can always toast the seeds and nuts to add a bit more flavor. Now, let's get started. Make sure that your product is clean and dry. Often there are bugs, rocks, or other debris in there and you don't want to grind those up into your flour. As a matter of fact, though the bugs ...

Should I choose a Roller Mill or Hammer Mill Grinder Mixer ...

In contrast, the Roller Mill Grinder Mixer operates at a much slower speed than the Hammer Mill Grinder Mixer. This type of grinder produces a more consistent particle size with increased bulk. The variable parameters of the Roller Mill are feed rate, quality of feed, and power to the Roller Mill and roll spacing. The fixed parameters of the Roller Mill are roll corrugations (number per inch ...

10100ton/D Maize Milling Plant | maize milling plant ...

Mini maize milling plant (corn milling plant) is composed by cleaning equipment, peeling degerming equipment, and maize flour equipment or maize grit making equipment. This unit adopts advanced peeling and degerming technology that can extract pure endosperm. By the grinding of maize milling machine, and the grading of bolting equipment, this unit can make high quality maize (corn) grits and ...

Understand the Distinction Between Crushing Equipment and ...

· Coarse grinding is able to mill materials to mm, fine grinding to about to mm, and ultrafine grinding to to mm or even smaller. Crushing plant is to crush a variety of ...

difference between wet dry grinding mills

The Corn wetmilling process is designed to extract the highest use and value from each . More. Dry Grind vs. Wet Grind For Sharpening Lathe Tools. Here is what I have found out so far about grinding and wet vs. dry: Dry: Plus: 1. The learning curve is relatively quick. 2. Relatively low cost low speed (1750 rpm) grinders available. 3. Reasonable cost jigs available especially for ...

(PDF) Hammer Mill Versus Roller Mill Grinding of Corn for ...

Deaton et al. (1989) showed no difference in layer performance between hens fed hammermilled corn diets with MPSs ranging from to or with rollermilled corn diets with MPSs ranging ...

MILLING OPERATIONS TYPES OF MILLING MACHINES

The basic difference between a universal horizontal milling machine and a plain horizontal milling machine is the addition of a table swivel housing between the table and the saddle of the universal machine. This permits the table to swing up to 45° in either direction for angular and helical milling operations. The universal machine can be fitted with various attachments such as the indexing ...

Difference Between Up Milling and Down Milling

· Differences between up milling and down milling. Up Milling Down Milling; In up milling, cutter rotates against the direction of table feed. In down milling, cutter rotates along the direction of table feed. Chip load on teeth (or uncut chip thickness) increases gradually from zero at the point of engagement to maximum at the point of disengagement. Chip load on teeth (or uncut chip .

Latest Posts

- أفضل معدات العثور على الذهب

- ماكينة ضخ الرمل مصر

- كسارة لفة باهان konstruksi

- دولوميت سحق الفحم

- أكبر مصنع معدات الطحن

- سحقت الدولوميت للبيع

- سحق 2tph مع vsi من puzzolona

- علف دواجن بيليه مطحنة hkj

- كسارة الفك في رانشي

- تكلفة مطحنة الكرة لطحن نانو الحجم

- آلات ومعدات التعدين والذهب

- المؤسسة العامة الفك محطم لوحة تبديل

- المصنعة جايبور محطم

- تشانكادورا سانتا كروز بوليفيا كورونيل

- مصنع كسارات في الجزائر

- Calcium Production Process From Dolomite

- Efficiency Of Coal Mill

- Mineral Grinding Machinery Raymond Mill

- Cost Of Coal Screening Machines

- Portable Gold Ore Cone Crusher Provider Luxembourg

- For Drum Crusher

- How To Remove Fines From Stone Crush

- Swift Marshall Price Index

- Name The Ores Of Iron With Its Chemical Formula

- Conveyor Manufacturer For Mining Industry Separating Pl

- Buyer Of Gypsum Ore In Honduras

- Drawing Of Sand Washing Machines

- Pulverizer Manufactures From Tamilnadu

- Glass Screening And Crushing Equipment Uk

- Crusher Hammer Crusher