Energy Used At Sag Mill

.:. tools

Estimates the critical speed of a grinding mill of a given diameter given the mill inside diameter and liner thickness. If given a measured mill rotation (RPM), then the mill`s fraction of the critical speed is given. Internet Slide Rule: A working webbased version of history`s most used advanced calculation device. Available with 1 to 4 cycles and a special Metric to Imperial conversion ...

The operating principle of the ball mill

· Energy consumption for ball mills is a function of many factors: the physical properties of the ground material – its specific gravity and hardness; the degree of drum filling by grinding balls; the number of drum rotations, etc. Ball mills have low efficiency – no more than 15%. Energy is mainly consumed on the wear of grinding balls and mill housing, friction; heating the material etc.

Sag and Tension Calculations

Refinements and Enhancements Made by Trimble Energy Solutions by: Jacques Hamian and Yair Berenstein Abstract Sagtension programs have traditionally calculated the conductor's sagtension characteristics using the ALCOA graphic method. By refining the input used in this equation, and augmenting these results with other definable variables and selectable parameters, Trimble has .

Modelling SAG milling power and specific energy ...

In these circuits the SAG mill is the largest energy consumer. In many engineering projects either a power equation and/or a specific energy equation are used for the designing of these mills but not always with acceptable results. In general these equations are used to predict power consumption as a function of mill size, level and density of ...

Semiautogenous grinding (SAG) mill liner design and ...

The energy required is a minor proportion of SAG mill power and this proportion falls as the liners wear (and lifting capacity falls) even when mill speed can be increased. The major proportion of mill power is used to turn over the mill charge. It follows that repeated ballrock shortrange lowenergy impacts within the tumbling charge are a significant proportion of the overall rockbreakage ...

![[Direwolf20] How To Power The Sag Mill Early On ...](/jicrp2l/582.jpg)

![[Direwolf20] How To Power The Sag Mill Early On ...](/jicrp2l/273.jpg)

[Direwolf20] How To Power The Sag Mill Early On ...

Some API mismatch or something. You need to use an energy conduit or a leadstone energy cell or something to connect them. To get the machines running temporarily you can use a Stirling generator or something. 7. Share. Report Save. level 2 · 7y. Infinity. Yeah, ran in to that problem myself and went to create a leadstone cell since using Ender IO conduits was out of reach with no ender ...

Medieval Technology and American History

The picturesque Dutch windmills used the energy available, as was also done on the American plains. The windmills used sails attached to axles that moved the millstones. Medieval engineers had to overcome various problems, of which one was their variable rate. Winds could be too still to turn the mill sails or so wild that they pulled the sails from the building. Gently flowing streams could ...

Hydroelectric Energy | National Geographic Society

· Hydroelectric energy, also called hydroelectric power or hydroelectricity, is a form of energy that harnesses the power of water in motion—such as water flowing over a waterfall—to generate have used this force for millennia. Over two thousand years ago, people in Greece used flowing water to turn the wheel of their mill to ground wheat into flour.

Energy Efficiency In Ag And Sag Mills

SAG Mill Circuit Example — Gold Processing SAG mill circuit example for gold processing [image: (13563)] AG/SAG Mill. AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill . Get Price. Ball Mills. Oleg D. Neikov, in Handbook of ...

Energy And Nutrition Bars Market By Type, By Technology,

· Energy And Nutrition Bars Market By Type, By Technology, By Output Type, By End User, By Regional Outlook, COVID19 Impact Analysis Report and Forecast, 2021 – 2025 | Kellogg's, General Mills ...

ITP Steel: Energy Use in the Steel Industry: An ...

hours during this same time frame (under 1 hour for the newest mills); and since 1950 energy consumption has declined from around 45 to 18 million Btu/ton (see Figure 6). Energy Use in the Steel Industry 1. With these reductions in energy consumption in mind, this study aims to accomplish the following: 1. Explain how the historical reduction in energy consumption was achieved and offer ...

Fact sheet Energy use in the steel industry

Energy use in the steel industry Fact sheet World crude steel production reached 1,860 million tonnes in 2020. Steel use is projected to increase steadily in the coming years to meet the needs of our growing population. Energy use in steelmaking Steel production is energy intensive. However, sophistied energy management systems ensure efficient use and recovery of energy throughout the ...

Morrell MethodGMGICEv01r01 Morrell method for ...

Fine Particle Tumbling Mill Specific Energy 12 Size Distribution Correction 12 Total Net Comminution Specific Energy 12 ... bling mills (AG/SAG, rod, and ball mills) involved in reducing the size of the primary crusher product to that of the final product (usually the cyclone overflow of the last stage of grinding prior to flotation/leaching). 2. Feed rate to the circuit ...

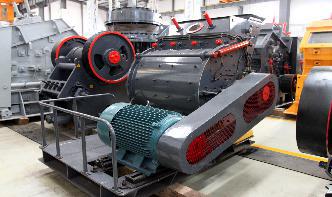

Used Processplants For Sale

Components from 3,0005,000 TPD Plant including 3,000 HP FLS Ball Mill, 3,000 HP SAG Mill, SLon Outotec Magnetic Separators, Pumps and Much More! Manufacturer: Various. Inventory ID: 18CMA01. View Details. TPD: USED 5,000 TPD Phosphate Minerals Processing Facility Components, including equipment for primary crushing, milling, classifying, filtering, drying, and more . Inventory ID: 18C .

Fluidized Energy Mill: Operating principles, subclasses ...

· c. Fluidized energy mill is used for the fine grinding of frits, Kaolin, Zircon, titanium, and calcium, alumina. Advantages of Fluidized Energy mill. 1. The machine has no moving parts and thus the tendency of contamination due to wear of parts is minimized. 2. The equipment is easily sterilized. 3. Small particle size (between 2 and 10) is usually obtained at the end of milling. 4 ...

Energy Consumption in Mining Comminution

· Although SAG mills and Ball mills are commonly used to decrease the size of ore bearing rock, the mining industry is 143 Jack Jeswiet and Alex Szekeres / Procedia CIRP 48 ( 2016 ) 140 â€" 145 driven to decrease costs, as are all industries. This means increasing comminution efficiency and decreasing energy costs. Stirred mills [17] have been found to be 50% more efficient than Ball mills ...

energy efficiency of sag mill

Optimizing your SAG mill operation · In the past, when primary, secondary and tertiary crushers fed material directly to large ball mills, the energy efficiency of the concentrator was determined for the most part by the ball mill operation, whereas now the energy efficiency of a plant often rests largely on the SAG mill operation.

BHP targets Mount Keith ramp up

· BHP has set itself to expand production by 40 per cent at its Mount Keith nickel mine in Western Australia, with a new SAG mill, flotation technology and two new excavators.

Use of energy in industry

· Manufacturing energy consumption includes fuel and nonfuel sources. Manufacturers consume two general types of energy sources—fuel and consumption is the use of combustible energy sources to produce heat and/or to generate electricity (which, by manufacturers, is mostly for their own use), and the use of electricity to operate equipment and associated .

Energy Use in US Steel Manufacturing

This means that energy use for electric arc furnace production will be approximately × 10 9 J per ton of steel, 10× less energy than production from raw iron ore. Even if the electric arc furnace is used to melt scrap steel and then the molten steel is reheated in a basic oxygen furnace, you will still on have × 10 9 J per ton of steel.

Bioenergy | Energy NSW

Sugar mills use bagasseproduced electricity and lowpressure waste steam for sugar milling and refining processes. Three of our biggest are: Broadwater Bioenergy Plant – capacity 38 megawatts (MW) Condong Bioenergy Plant – capacity 30 MW Harwood sugar mill – capacity MW Other electricity producing bioenergy facilities include: Tumut Visy Paper Bioenergy Facility (32 MW capacity ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

AG/SAG Mill. AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill red=fastest, blue=slowest moving particles [image: (13564)] The mill product can either be finished size ready for processing, or an intermediate size ready for ...

Energy Cost Reduction in the Pulp and Paper Industry

The energy use for a particular mill can be compared with that for similar mills or with that for a model mill representing the current best practice. To illustrate the potential to reduce energy consumption and greenhouse gas (GHG) emissions, benchmarking studies were performed for the two largest production segments of the Canadian pulp 5 Energy Cost Reduction in the Pulp and Paper ...

Archemedes: Wind Energy

The brand named after the famous Greek mathematician and engineer, the Archimedes Wind Mill can produce 1500kWh of energy at wind speeds of 5m/sapproximately half an average Indian 's uses. This Mill is an outcome of 20 years of R D (Research Development) by a Dutch scientist Marinus Mieremet. He has perfected the technology using the principle of Archimedes screw, as a .

Latest Posts

- سعر معدات الغسيل المستعملة في سنغافورة

- كسارة عملية تصنيع الأسمنت لخبز

- محجر الجرانيت للبيع في اونجول

- مطحنة الكرة للبيع وسعر المصنع البرازيل

- سعر الكسارة المحورية للبيع في المملكة العربية السعودية

- كسارة تصادمية أقصى عامل تكسير

- نباتات ترشيح الذهب المحمولة المصنوعة في الولايات المتحدة

- طحن الكرة الجافة طحن

- كسارة فكية غرب الجزائر

- سعر معدات سحق الحجارة سنغافورة

- مورد مصنع خام الحديد في مصر

- الحجر الجيري طحن مطحنة الألمانية

- الأنتيمون مطحنة الكرة خام لسحق

- كسارة فحم 300 طن يوميا 500 يوميا

- استخدام كسارة الفك للبيع تاميل نادو

- Gangue Production Equipment Price

- Concrete Soil Machine

- Foundry Sand Reuse Resource Locator

- Knife Sharpening Machine Manufacturer In South Africa

- Process Of Marble Crushing Stones In Pakistan

- Impact Of Mining On Local Communities

- Common Chemical Formula For Iron Ore

- Hammer Grinder Muyang

- Sketches Of Burr 2 Hammer And Roller Mills

- Grinding Machines In Poland Software

- Mfr Of Ball Mills

- Nishat Mills Barite Crushers

- List Of Crushers In Tirunelveli District

- Dewatering In Open Pit Mining Zaman

- Project Report On Grinding Machine Market Survey