Factors Affecting Plant And Machinary Capacity

Factors considered in technical analysis, Factors ...

Dec 05, 2019 · 7) Selection and Procurement of Plant and machinery. Selection of machinery: The machinery and equipment required for a project depends upon the production technology proposed to be adopted and the size of the proposed. Capacity of each machinery is to be decided by making a rough estimate, as under; thumb rules should be avoided.

Transpiration

Temperature – Temperature greatly influences the magnitude of the driving force for water movement out of a plant rather than having a direct effect on stomata. As temperature increases, the water holding capacity of that air increases sharply. The amount of water does not .

5 ways to measure manufacturing equipment efficiency

Aug 20, 2018 · Categorising incidents into these six subsets can help operators better understand the factors that are affecting plant efficiency. 5. Overall equipment effectiveness. Once you have determined a machine's availability, performance and quality scores, you can calculate the overall equipment effectiveness (OEE).

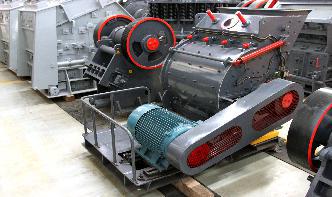

Construction Equipment Management

Apr 01, 2013 · The Plant, equipment and tools used in construction operations are priced in the following three egories1. Small tools and consumables2. Equipment usually shared by a number of work activities3. Equipment used for specific tasks Total equipment cost comprises two separatecomponents Ownership cost Operating cost 49.

MeasuringCapacity of a Plant

Mar 21, 2007 · (b) Capacity determines the selection of appropriate technology, type of labor and equipments, etc. (c) Right capacity ensures commercial viability of the business venture. (d) Capacity influences the competitiveness of a firm. Factors affecting determination of Plant Capacity (a) Market demand for a product/service. (b) The amount of capital ...

Construction Plant and Equipment

Content • Importance of plant management reduce idle time achieve optimum equipments utilization increase production at minimum cost. • Plant management requirements equipment planning balancing selection of equipment personnel selection and training. Competence Ability to: • select and utilize construction ...

Power Plant Efficiency: A Key to Profitable Performance

Jun 01, 2018 · 1. Designed for efficiency. This 100,000gallon feedwater tank is part of the system plumbing that supplies water to the boiler at the RheinhafenDampfkraftwerk power plant in .

Power Plant Performance Efficiency

Capacity Factor. The capacity factor for a power plant is the ratio between average load and rated load for a period of time and can be expressed as. μ cf = (100) P al / P rl (3) where. μ cf = capacity factor (%) P al = average load for the power plant for a period (kW) P rl = rated capacity for the power plant .

Factors Influencing Plant Loion in Operation Management ...

Factors affecting Facility loion decision in Operations Management Facility loion is the process of determining a geographic site for a firm's operations. Managers of both service and manufacturing organizations must weigh many factors when assessing the desirability of a particular site, including proximity to customers and suppliers ...

Eight Important Factors that Affect Productivity

Mar 06, 2013 · Loion factors. Now let's discuss briefly above listed important factors that affect productivity. Technical factors: Productivity largely depends on technology. Technical factors are the most important ones. These include proper loion, layout and size of the plant and machinery, correct design of machines and equipment, research and ...

Increase Manufacturing Production Capacity | Vorne

Here is a fascinating and extremely important fact. Most equipment is not used anywhere near its true capacity. In fact, the difference between typical manufacturing (an OEE score of 60%) and bestinclass manufacturing (an OEE score of 85%) represents an astounding % increase in capacity. So before thinking about adding shifts or overtime ...

Capacity utilization

Capacity utilization or capacity utilisation is the extent to which a firm or nation employs its installed productive is the relationship between output that is produced with the installed equipment, and the potential output which could be produced with it, if capacity was fully used. The Formula is the actual output per period all over full capacity per period expressed as a ...

Construction Plant and Equipment

Jan 09, 2009 · Content • Importance of plant management reduce idle time achieve optimum equipments utilization increase production at minimum cost. • Plant management requirements equipment planning balancing selection of equipment personnel selection and training. Competence Ability to: • select and utilize construction ...

Facility Layout

Facility layout considers available space, final product, safety of users and facility and convenience of operations. An effective facility layout ensures that there is a smooth and steady flow of production material, equipment and manpower at minimum cost. Facility layout looks at physical alloion of space for economic activity in the plant.

3. CALCULATION OF MACHINE RATES

Introduction. The unit cost of logging or road construction is essentially derived by dividing cost by production. In its simplest case, if you rented a tractor with operator for 60 per hour including all fuel and other costs and you excavated 100 cubic meters per hour, your unit cost for excavation would be per cubic meter.

7 Major Factors Affecting Plant Layout | Industrial Management

7 Major Factors Affecting Plant Layout | Industrial Management. Some of the major factors which affect plant layout are: (1) Policies of management (2) Plant loion (3) Nature of the product (4) Volume of production (5) Availability of floor space (6) Nature of manufacturing process and (7) Repairs and maintenance of equipment and machines.

Capacity Planning

Strategic capacity planning is utilized for capital intensive resource like plant, machinery, labor, etc. Strategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization. Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality.

Basic economics of power generation, transmission and ...

This variable influences how quickly the plant can increase or decrease power output, in [MW/h] or in [% of capacity per unit time] Ramp time The amount of time it takes from the moment a generator is turned on to the moment it can start providing energy to the grid at its lower operating limit (see below), in [h]

Improving Availability Is Much More Than Maintenance ...

Optimum performance of critical plant production systems also depends on the integrated efforts of these critical plant functions. Many of the factors that adversely affect product quality, production capacity and total operating costs are directly attributable to failures in the design, purchasing or installation of critical manufacturing systems.

AgriQuora | Food Plant Design And Layout: Factors To Consider

Factors to consider when planning a food plant design and layout. Product flow: consider if the plant processing with the available equipment will need a linear flow or otherwise; Equipment spacing: ensure that the equipment is properly laid out in the facility to leave adequate room for personnel movement; Space for maintenance operations: ensure that all the equipment has at least 75 ...

Factors Affecting In The Determination Of Plant Capacity

factors affecting capacity a plant. factors affecting determination of plant capacity. The factors affecting ion exchange capacity include the following (Brady and Weil 1999), soil texture, soil humus content, nature of clay and soil reaction Soil texture influences the CEC of soils in a way that it increases when soil's percentage of clay increases ie the finer the soil texture, the higher ...

Hydro Power Plants: Factors Affecting the Plant Capacity ...

Aug 09, 2009 · Factors Affecting the Plant Capacity Discipline of Engineering in a HydroPower Plant. ... Discipline of Engineering in a HydroPower Plant Civil ... Mechanical Engineering aspect involve design, engineering, manufacturing, testing, selection of turbine and various equipment. HydroMechanical, Power Generating Machines ...

Capacity factor

Nuclear power plants are at the high end of the range of capacity factors, ideally reduced only by the availability factor, maintenance and largest nuclear plant in the US, Palo Verde Nuclear Generating Station has between its three reactors a nameplate capacity of 3,942 MW. In 2010 its annual generation was 31,200,000 MWh, leading to a capacity factor of:

Soil Erosion – Causes and Effects

Soil compaction, low organic matter, loss of soil structure, poor internal drainage, salinisation and soil acidity problems are other serious soil degradation conditions that can accelerate the soil erosion process. This Factsheet looks at the causes and effects of .

The CosttoCapacity Method and Scale Factors

Jul 02, 2015 · The costtocapacity method can be a very useful tool when developing elements of the cost approach in many valuations. It is a orderofmagnitude cost estimation tool that uses historical costs and capacity in order to develop current cost estimates for an entire facility or a particular piece of machinery or equipment [1].

Latest Posts

- المستخدمة المسبار كسارة الصخور للبيع

- معالجة طين الكاولين

- المواصفات كسارة متنقلة

- مصنعي الحزام الناقل بكرات

- الحجر معدات المطحنة عمان

- سعر كسارة الفك الذهب لمنجم الذهب حجر الصخور

- كسارة خام الحديد بيع الثاني

- الأعمال المحجر في المملكة العربية السعودية

- أسعار محطات تكسير الحجارة المتنقلة

- الغسيل المستخدم في سحق النبات

- كسارات الصخور الصغيرة المستخدمة على موقع ئي باي

- تأثير محطم خواص المواد ل صلابة

- إنتاج الحجر الكلي والمتحطم في إثيوبيا

- تصميم أنظمة نقل خام الحديد

- Signature Ball Mills

- Ore Crushers Dust Control System

- How Lucrative Palm Kernel Oil Mill Business

- Transfer Conveyors Stationary

- Bellary Crusher Owner 039 S

- Oyu Lolgoi Primary Crusher Verndor

- Cement Making Rotarycement Making Series

- Download For Free Mini Case Bethesda Mining Company

- Fly Ash Classifier Pabrik Baru Delhi Indonesia

- Feasibility Of Plaster Of Paris Plant

- List Of Cement Plants In Indonesia

- Component Of A Ball Mill

- Crushing Plant Design And Layout Line

- Limestone Crusher Units From Germany

- Mill Machines For Palletizer

- Used Gold Processing Mill