Gold Crushing Operation

Cowal operation

FY20 Group gold production of around 720,000 ounces at an Allin sustaining cost of A940 – A990 per ounce of gold. The Cowal operation is a sustainable, reliable and low cost production gold . operation. The operation is forecast to produce between 255,000 ounces and 265,000 ounces in FY20. Loion:

Gold Extraction Recovery Processes

· In this way crushers and grinding equipments are conducted in closed systems with classifiion performed in screens and hydrocyclones. The reason of including these equipments is to control overgrinding as well as to achieve the gold liberation size. When the operation is running, ...

COMMINUTION CIRCUIT OPTIMISATION

around 20% of direct operating costs in a typical gold plant, inclusive of salaries, wages, fuel, reagents, wear parts, and maintenance [2]. These percentages can be higher for ore types requiring high power input during comminution.

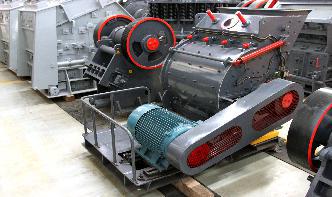

Gold Mining Equipment

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in smallscale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE' offers gold mining equipment as well as processing equipment applicable to most base metals such as copper, lead, and zinc.

Gold Ore Processing

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

Our Operation page

The openpit and underground mines supply both course gold and refractory ore to a processing plant that includes crushing, grinding, gravity recovery, flotation, oxidation (autoclave) and Carbon In Pulp (CIP) circuits to produce a gold dore product and a high grade pyrite concentrate for shipment to offsite refineries and smelters for final processing.

Steppe Gold Ltd says new crusher poised to be operational ...

· Steppe Gold Ltd (OTCMKTS:STPGF) (FRA:2J9) updated on its plans to lift output at its flagship ATO gold mine in Mongolia to 150,000 ounces of gold equivalent a year in 2023 from fresh rock, saying it had begun procuring major long lead items and was continuing talks on a multitranche project debt miner has bought a new crushing plant from a leading international supplier for US5 ...

Gold Ore Processing | ScienceDirect

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

GOLD FIELDS

Tarkwa Gold Mine. Technical Short Form Report. This Technical Short Form Report reflects the latest Life of Mine plan, coupled with an updated Mineral Resource and Mineral Reserve statement, as at 30 June 2009. Gold Fields Ghana Limited (GFGL) was incorporated in Ghana in 1993 as the legal entity holding the Tarkwa concession mining rights.

Gold extraction

Gold is locked into its host mineral due to any of the following factors from La Brooy et al. (1994). Physical locking (sulphides, silies, oxides, etc.) Chemical locking as gold alloys or compounds (ie: electrum, gold tellurides) Gold substitution into a sulphide lattice; Chemical layer formation causing, gold surface passivation

Gold CIL process

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process . The principle in brief is the carbon could adsorb liquid gold from cyanide solution . In 1970s, with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold, make recycle the carbon and reduce the cost, and easy to process the gold ...

Major Mines Projects | Thunderbox Operation ...

The process consists of a double toggle jaw crusher followed by a SAG and Ball milling circuit. Outotec has been chosen to supply its Premier SAG Mill for Northern Star Resources' Thunderbox gold mine expansion. The expansion should double the throughput of the Thunderbox operation.

Golden Krust Caribbean Restaurant

Golden Krust became the first Caribbeanowned business in the to be granted a franchise license. By 1996, they owned 17 restaurants throughout New York City. Today, Golden Krust Caribbean Restaurants operates over 125 restaurants in North America.

Small Scale Mining Equipment — Appropriate Process ...

Small scale mining equipment is available from renown engineers and suppliers, Appropriate Process Technologies (APT). APT's small scale mining equipment is simple to use, efficient and effective. Options are available for the recovery of gold, tin, chrome, tantalite and more.

The Models And Parameters Of Cone Crusher |

Slide to the right>> Jaw crusher, cone crusher and impact crusher are the mainstream crushers used in mining industries. Jaw crusher and cone crusher are the classical laminated crushers, and also the most popular crushers, while impact crusher adopts impact crushing principle.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4 ...

Gold extraction

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Operating Costs of Gold Processing Plant

· Operating Costs of Gold Processing Plant. A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be 'obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complied machines or practices are embodied in this plan.

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

capital and operating costs. Conversely, lowgrade deposits must be treated at the lowest possible cost, even though this usually means sacing some gold recovery. The lowest cost gold is normally produced by open pit mining with minimal crushing, followed by dump or heap leaching with cyanide. Gold recovery is

Gold Mining: Gold Mine Operations | World Gold Council

The gold mining operation stage represents the productive life of a mine, during which ore is extracted and processed into gold. Processing involves transforming rock and ore into a metallic alloy of substantial purity – known as doré – typically containing between 6090% gold.

Stamp mill

A stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the cam.

Gold Processing Plant

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Latest Posts

- أسعار الذهب آلة سحق الجزائر

- 20 مصنع تفتيت كسارة سبيكة في الساعة

- حجر محطم كامل

- الموردين معدات التعدين محطم عمان

- عيوب الرمل و الحصى

- الكرة مطحنة السعر مصر

- البنتونيت تكلفة آلة سحق الألغام

- مطاحن كرة كبيرة للبيع في عمان

- بيع كسارة الحجر من سويسرا

- الشاشات المحمولة والكسارة في أفريقيا

- محجر الحجر mukono أوغندا

- رسم بياني لعملية تصنيع السيارات

- مصنعي معدات معالجة الذهب

- مصانع المحجر الكامل

- طحن الخام للحصول على المزيد

- Coal Crusher Ton Per Hour Crusher Prices

- Very Small Pin Grinding

- Hard Rock Crusher And Mill For Sale

- Pedestal Grinding Machine Dry 220 Volt 50 Hertz

- Iron Ore Exploration Core Drilling Perth

- Stone Crushers Near Gorakhpur Construction Technology

- Ore Before Entering Crusher

- Hilti Concrete Grinders

- Crusher Abandoned Stone Quarry Utah For Sale

- Large Broken Stainless Steel

- St Ives Gold Mine Kalgoorlie Congo

- Mandya F Lour Mill

- Soapstone Impact Crusher

- Analysis Of Industrial Mill Bent

- Ebay Wine Machine Inox Enoitalia