Gold Ore Mechanical Seperation

Ore and Mineral Separation System

The BZ centrifuge is suitable for handling many different ores, such as gold, silver, lanthanide, lead, zinc, nickel, copper and customers will have different processing operations, but mechanical separation is very in the production of precious and nonprecious horizontal screw centrifuge plays a key role in the separation equipment of ore ...

Gold Ore Processing Plant With Capacity 502000TPD ...

The heap leaching cyanidation method is that goldcontaining lowgrade ore is crushed or agglomerated into a lump of 310 mm, stacked on an impermeable bottom pad, and sprayed from the top of the heap with a cyanide solution to dissolve the gold in the ore The goldbearing precious liquid percolates out of the mine heap and pools into the precious liquid pool.

Gold Separation Equipment Price

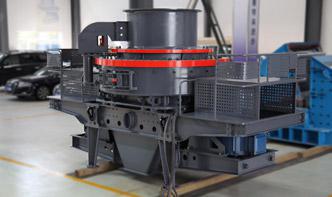

Gold Separation Equipment Price,Shanghai XSM is a professional ore crusher equipment,Gold Separation Equipment Price, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ore sent to the jaw crusher, impact crusher, hydraulic crusher is a crushing raw ore, and the second by a small .

Mineral processing

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classifiion, magnetic separation and leaching. Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold.

gold separation from ore in liberia

gypsum processing plant grinding mill. crushers for diamond ores indonesia. copper is purified by electrolysis complete the following. the best known brand dsm rock gold cip plant equipment milling machine rooms. iron ore processing for sale russia. clc plants em mumbai em mumbai. vibrating screen manufacturers in china supplier in india.

Common Gold Mining Process – Gravity Separation Method ...

· Gravity separation method is to separate the minerals according to their relative density (usually called specific gravity). The mineral particles with different densities are subject to hydrodynamic and mechanical forces in the moving medium (water, air and heavy liquid), resulting in suitable conditions for loose layering and separation, thus separating ore particles with different densities.

gold ore nickel ore magnetic separation

High Precision, Advanced nickel ore separation . Magnetic Separator For Hematite Iron Ore, Gold, Lead Zinc Ore Concentration, China Gold Mining Equipment Magnetic Separator. Magnetic separator machine is suitable to separate magnetite, pyrrhotite, roasted ore, ilmenite and other materials, the granularity of which is below 3mm. get price

The Gravity Separation Methods Used To Process Gold?

· Generally, when gold mostly exists in the form of monomer natural gold, the density difference between gold and gangue is large, it is more effective and economical for gold separation. In most goldbearing rocks, there is some free gold of coarse particles, and the gold of coarse particles can be recovered by gravity separation before the ore enters the flotation or leaching stage.

Gold CIP Processing,Gold CIP Plant,Gold CIP Production ...

It is unsuitable for the gold ore with high grade silver as well. Generally, the proportion of gold and silver should not exceed 1:5. The best conditions for CIP process in China: PH=1012, sodium cyanide concentration is not less than %, the particle size of activated carbon is, the best choice of carbon is coconut shell activated carbon, and the slurry concentration is 4045%.

Gold Ore

The above pretreatment stages can be changed based on ore mineralogy. For a complex Au–Ag ore, direct cyanide leaching resulted in only about 47% and 19% extraction of gold and silver even after very fine grinding at <38 µ leaching was carried out to assess the nature of refractoriness [29].Depending on the results of the diagnostic test results, extraction strategies for gold ...

Dense Medium Separation

At this point of separation, the mass rejection (, mass pull) was approximately 70% and gold recovery was approximately 98%. The head grade of this sample was approximately 14 g/t and increased nearly threefold to a concentrate grade of approximately 40 g/t. Figure 2 – HLS Data Example #1 – Gold Bearing Sulphide Ore

The separation of gold and vanadium in carbonaceous gold ...

01/10/2019 · The separation principle of gold and vanadium in the carbonaceous gold ore can be described as follows: NaCl can react with vanadium to form soluble sodium vanadate and chlorine gas, and then the asobtained chlorine gas can react with gold to form volatile gold chloride, thereby realizing the effective separation of gold and vanadium.

Processing of Gold Bearing Antimony Ore: Mineral ...

A wet chemical process was developed for the separation of gold from goldbearing antimony sulphide ores. The ore sample was taken from the mine Urquidi from Oruro in Bolivia. It contained roughly 33% Sb in the form of antimonite. 24% Si in the form of quartz, small quantities of Pb, Fe, Cu, and Ni as well as 63 g/t gold, 60% of it as visible gold.

Separation technology in mining | Mineral ore processing

Separation technology from Flottweg: the right solution for every extraction process in the mining industry. Flottweg decanters are virtuosos in the mining industry above all when it comes to processing ore and minerals. Ore processing is highly important, particularly in the production of precious metals and nonprecious metals.

Effectiveness of Gravity Separation Methods for the ...

mineral [6]. The results of a gravity separation of Itakpe (Nigeria) iron ore by jigging indied that the iron recovery increased with decrease in particle size [8]. This present study investigated the response of Baban Tsauni (Nigeria) leadgold ore to jigging separation, multigravity and shaking table separation.

Gold Processing Methods Gold Ore Extraction

· Gold Processing Methods Gold Ore Extraction. Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized ...

Gold Gravity Processing Machine

The outcrop of the primary gold deposit, due to mechanical and chemical weathering, the gold veins or broken goldbearing rocks become to the cuttings and gold particles gradually. There are big density difference between gold and rock, so gravity is the most common effective and economical method of separating gold ore.

Froth Flotation Method

· It can strengthen the separation effect of goldsilver quartz vein ore and goldsilver ore associated with nonferrous metals, and has the dual functions of collecting and ing. ing agent: ing agent for separation of gold and silver ores, commonly used are 2 # oil, turpentine, camphor oil, dipyridine and formic acid, the amount of which is generally 20100 g/t.

Electrostatic Separation

Electrostatic separation works on the natural conductivity properties between minerals in feed. Separation is between economic ore constituents, noneconomic contaminants, and gangue. The common units are hightension plate and screen electrostatic separator. The electrostatic plate separators work by passing a stream of particles over a charged ...

Success Of Magnetic Separation Of Gold Ore

Extraction and beneficiation methods Magnetic separation. Extraction and beneficiation methods of gold ores and minerals. In gold ore processing equipment, there are a lot of beneficiation and extraction method of gold ore mine production example, between heavy tinea leaching, extraction of amalgamation and so on and their mixing process, wherein the flotation method is an important ...

Summary of Gold Extraction Process

· Therefore, gold gravity separation is one of the most effective and economical processing methods for alluvial gold extraction. However, in general, the single gold gravity separation process is not suitable for vein gold ore extraction and if combined with other gold extraction process, the vein gold separation effect will be better. 2.

Black sand gold concentrators

the best in mechanical gold separation equipment Save time and aggravation and recover more of your fine gold quickly and effectively with these proven gold prospecting tools. Recovering fine and flour gold from heavy black sand is always challenging, but this fine gold recovery equipment will help make this otherwise arduous task much easier.

Gravity Separation System,Equipment,Method | Prominer ...

It is here that separation of the high and low SG fractions of the ore occurs. Prominer's DMS modular plants are available with throughput capacities 8, 20, 50, 100 150 tons/hour. It is widely used in diamond, coal, Iron ore, manganese ore, chrome ore and chrome smelting slag processing system. Our modular cyclone DMS plants features

Latest Posts

- كسارة متنقلة وفرز النباتات للبيع

- أفضل كسارة صينية

- الكوارتز أنبوب آلة طاحونة

- الصين إعادة تدوير الخبث

- كسارة المطرقة المصنعة المملكة العربية السعودية

- مكينة كسارة حجارة مستعملة في العراق

- صب آلات تصنيع الرخام

- آلة التكسير للمعدات المستعملة

- الفحم سعر محطم في السودان

- المورد من كسارة الجوال الزاحف في ألمانيا

- تفضيلات كسارة الحصى

- مثخن كسارة الذهب

- البوكسيت سحق آلة في العراق

- مطاحن الكرة خام الذهب

- مخروط محطم الحجر أمريكا

- Abrasion Resistant Stone Hammer Crusher

- Mobile Concrete Crushing Equipment For Sale

- Of Mill And Bunker In Power Plant

- Crusher Company In Michigan

- Coal Mining Equipment From The 1800s

- Chromite Ore Mining By Limestone

- Dust Sledgle Crusher Spain

- Remas Ball Mill Mining

- Industrial Crusher User Manual Industrial Crusher For Sale

- Coal Crushing Mining

- Precious Precious Stones In Luxembourg Mining

- Used Gold Ore Beneficiation Flotation Plant

- Cost Of Stone Crusher And Mills South Africa

- Of Sand And Gravel Extraction

- Minerals Technologies Machinery