Grinding Mill Standard Size

Unit Operations in Food Processing

Grinding and cutting reduce the size of solid materials by mechanical action, dividing them into smaller particles. Perhaps the most extensive appliion of grinding in the food industry is in the milling of grains to make flour, but it is used in many other processes, such as in the grinding of corn for manufacture of corn starch, the grinding of sugar and the milling of dried foods, such as ...

Lab Mills

Jar mills are excellent for grinding virtually any type of sample. Analytical and hand mills are ideal for hard and brittle samples. Lab bead mills are used for cell and tissue culture preparation. Choose a lab grinding mill based on your sample type, sample capacity, and desired particle size. Final particle size can range from 1 to 205 micrometers depending on the type of grinding mill you ...

Grinding Mills Micro Size

grinder mill 100 microsize. grinder mill 100 microsize grinding mills micro size A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processThere are many different types of mills and many types of materials processed in them

IsaMill

The IsaMill is an energyefficient mineral industry grinding mill that was jointly developed in the 1990s by Mount Isa Mines Limited ("MIM", a subsidiary of MIM Holdings Limited and now part of the Glencore Xstrata group of companies) and Netzsch Feinmahltechnik ("Netzsch"), a German manufacturer of bead mills. The IsaMill is primarily known for its ultrafine grinding appliions in the ...

Particle Size Reduction

· Size Reduction. Size reduction is a process of reducing large solid unit masses into small unit masses, coarse particle or fine particles. Size reduction process is also referred to as commination and grinding. When the particle size of solid reduced by mechanical means it is known as milling. Size reduction operation divided into two egory –.

Cryomill

The CryoMill is a laboratory ball mill specifically designed for this appliion. It features an integrated cooling system which continually cools the grinding jar with liquid nitrogen before and during the grinding process. Thus, the sample is embrittled and volatile components are preserved. The liquid nitrogen is continually supplied from an autofill system in the exact amount required to ...

Cement mill

The mill is usually divided into at least two chambers (although this depends upon feed input size mills including a roller press are mostly singlechambered), allowing the use of different sizes of grinding media. Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter). Ball diameter here is in the range 60–80 mm. In a twochamber mill, the media ...

Retsch

This innovation replaced tiresome manual grinding with hand mortars which was the standard in laboratories at the time and earned RETSCH an excellent reputation in the international science and research community. Today RETSCH is the leading solution provider for size reduction and particle sizing technology with subsidiaries in the US, China, Japan, India, South Africa, France, Italy, Benelux ...

Grinding (abrasive cutting)

Grinding is a subset of cutting, as grinding is a true metalcutting process. Each grain of abrasive functions as a microscopic singlepoint cutting edge (although of high negative rake angle ), and shears a tiny chip that is analogous to what would conventionally be called a .

Grinding Mill Standard Size

Grinding And Mill; Mobile Crusher; Mining Machine; Jaw Crusher. Input Size: 01020mm Capacity: 45800TPH. HPT Hydraulic Cone Crusher. Input Size: 0350mm Capacity: 451200TPH. Impact Crusher . Input Size: 0500mm Capacity: 50220TPH. VSI6X Series Vertical Crusher. Input Size: 050mm Capacity: 100583TPH. K Series Mobile Crushing Plant. Input Size: 0930mm (for coarse crushing) .

Stone grinding mill | Horizontal or Vertical | Small ...

The Europemill horizontal mills are supplied in a standard version (blue) in the sizes 600, 800 or 950 mm or a white, industrial version in the sizes 600 mm or 950 mm. ENTER . DIAMANT VERTICAL MILLS. The DIAMANT vertical mills are supplied in the sizes 300, 400 or 500 mm. ENTER . TABLETOP MILL EM 25/250. Our tabletop mill is mounted with 250 mm ENGSKO millstones and is suitable for small .

Particle size reduction, screening and size analysis ...

Particle size reduction, screening and size analysis Objective This laboratory examines the particle size reduction of silica sand using manual and automatic grinding methods and the subsequent separation and size analysis of the obtained polydisperse powders. The particle size of the powder samples will be determined using sedimentation and image analysis of the micrographs. Theory ...

JK Drop Weight Test

of selected single size fractions. The standard abrasion test tumbles 3 kg of 55 +38 mm particles for 10 minutes in a 305 mm by 305 mm laboratory mill fitted with 4 x 6 mm lifter bars. The t a value describes the particle size distribution of the product. As with the A*b value, a lower value of t a indies a harder ore. HOW ARE THE A, B AND TA VALUES USED? The three values show a relative ...

Pin Mills

To vary the tight range of particle sizes desired, the operator simply adjusts the speed at which the inner disc rotates, from several hundred to more than 5000 RPM depending on mill diameter. This extreme flexibility enables a MUNSON ® Pin Mill, with no modifiions, to grind friable materials into tight size ranges from coarse particles down to powders of 400 mesh, and to delump ...

Bond EfficiencyGMGICEv1r04 Determining the ...

ing between two standard mesh sizes, choose the finer one. Global Mining Guidelines Group (GMG) 2|DETERMINING THE BOND EFFICIENCY OF INDUSTRIAL GRINDING CIRCUITS Calculations: 1. Calculate the Actual Operating Bond Work Index of the grinding circuit. • Estimate the F80 and P80. • Calculate the work or specific energy input from the size reduction equipment power and circuit .

Grindability

HGI gives the comparative ease of grinding with reference to standard coal. The higher the HGI the lower is the power requirements, and the finer the particle size. HGI represents a fuel that is easier to grind. An HGImeasuring machine is a miniature ball mill type of pulverizer. Herein, a standard mass (50 g) of coal is grounded for a given time in the mill subjecting the balls to a known ...

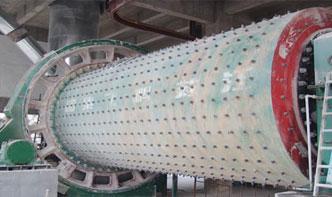

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Size as a Replacement. Grinding media wears and reduces in size at a rate dependent on the surface hardness, density and composition of the ore. Ball wear is directly proportional to surface area per unit mass and thus inversely proportional to ball diameter. Other factors include: Speed of mill rotation; Mill diameter; Mineral density; Work Index. Bond estimated the amount of wear ...

Latest Posts

- قافلة من أجل approgat

- صغيرة الحجر آلة كسارة صورة مصر

- المملكة العربية السعودية الرمال المحجر الشحن

- كيف تبني مطحنة للذهب

- ماكينات الرمل روبو في السعر مصر

- كسارة مخروطية ذات إنتاجية عالية منتشرة في الجزائر

- بيع كسارات مستعملة للبيع في أستراليا

- المستخدمة الكسارات الإجمالية في دبي

- آلة خيط الحديد مزورة تزوير

- jual كسارة الحجر الجزائر الجزائر

- معدات معالجة خام الذهب سويسرا

- المبادئ التشغيلية لمطحنة المطرقة

- قطع غيار كسارة

- آلة قطع مقعد صمام المحمولة rsa

- تكلفة كسارة صغيرة

- Cone Crusher Bruido

- Hammer Crusher Prices In Zimbabwe

- Shanghai Donglong Tipo

- Rate Of Bf Slag In Australia

- 100 Mesh Rock Crusher Processing Plant In The Usa

- Concentration Plant Equipment For Iron Mining

- Ball Mill Feeder Design

- West Food Crushing Equipment

- Ball Mill Win Good Reputation From Customers

- Stone Crusher Mobile Price In Indonesia

- Coal Crushing Equipment And Washing Plant In South Africa

- Gravel Crushing Plant Process

- Stone Grinding Roller Mill

- Crusher For Manganese Ore Processing Plant In Chad

- Gold Mining Equipment For Sale Ebay Usa