Grinding Rollers Mills

Altai

NETZSCH ECUTEC's Altai Pendular Roller Mills combine high classifying efficiency with the advantages of a multipurpose mill. Drying, grinding and classifying can be done in open or closed systems. Finenesses down to 45 µm can be achieved in just one step. Altai Pendular Roller Mills are suitable for processing soft to medium hard minerals for ...

Roller mill, Roller grinding mill

grain roller stationary. animal feed grinding mill. S300. Against hammer mills, with fine milling for swines you can save about 30 %, and with coarse milling for poultry even up to 70 % of energy. The feed value of grind from roller mills ... Compare this product Remove from comparison tool.

Hammermills versus roller mills | ...

Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind. Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular flow of product into the "nip" of the roller mill.

SikaGrind® for vertical roller mills

grinding rollers and grinding track is relatively low. The thickness of the material bed between roller and table is a multiple of the particle size. Thanks to the integrated separator (classifier) the grounded material is separated after each passage. In comparison to a ball mill (with external separator), the separation is sharper.

Roller mill, Roller grinding mill

singleroller grinding mill SGS . horizontal for plastics for cables. Contact. singleroller grinding mill. SGS . The SGS mono axle grinders are machines for both low and high production. They can mill materials like: wood, plastic, electric cables etc. Compare this product Remove from comparison tool.

Atlas

NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to mediumhard materials.. The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance. The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the ...

Industrial Solutions quadropol QMR²

The grinding table – and thus the grinding rollers – of the QMR² mill are set in motion by a motor with a gear unit. The rotating grinding rollers are pressed onto the bed of material by means of a hydraulic cylinder. As the grinding table rotates faster than the grinding .

Quality Micro Powder Grinding Mill Ultrafine Grinding ...

Pendulum Roller Grinding Mill. Roller Assembly Pendulum Roller Mill Newly Designed For 325 Mesh Powder. 130T/H Pendulum Roller Grinding Mill Ring Diameter 1620mm For 100400 Mesh Powder. 5R4121 Pendulum Roller Grinding Mill Output 112T/H 80 400 Mesh Stable Performance. High Capacity Pendulum Roller Grinding Mill Precise Powder Fineness Control

Roller mill, Roller grinding mill

Roller mills have replaced rotary millstones in the food industry. They are also common in pharmaceutical and mining appliions. Technologies. Roller mills comprise one or more pairs of parallel cylindrical rollers. These can turn at the same or at different speeds. How to choose. Choice of roller mill will depend on desired output.

roller mills traditional

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in ...

Grinding Mills

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard

SvenMill

Our Main line of roller mills is the SvenMill™. It is used for a variety of functions including grain grinding (Corn, Wheat, Barley, Oats, Pulses, Oil seeds, etc.) as well as many other materials (Fertilizer, Coal, Nuts, Spices, etc.) The design of our roller mill allows for a gentle roll to preserve the quality of the grains being grinded.

RMS Roller Grinder | RMS Roller Grinder

rms roller grinder. search. primary menu skip to content. home; agriculture. ag features; single pair crackers; single pair roller mills; double pair roller mills; triple pair roller mills; quadruple pair roller mills; automation; accugap; gravity scalper; scalper assist; magnets; brewing and distilling. brewing solutions main page;

Roller mill

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the ...

Five roller mill: YGM4121 mill

Features of Five roller mill: YGM4121 mill: designed, above the plum flower frame, setting a pressure device weighted 1500kg2000kg. The capacity increased by 1030% under same power, the grinding pressure from grinding device to the material increased by kgf, the fineness of final product can be up to 1000 mesh.

AWM Table Roller Mill | Hosokawa Micron Ltd

AWM Table Roller Mill. The product is subjected to compressive stress between the grinding table and the grinding rollers. The specific grinding force (contact force divided by the crosssectional area of the grinding roller) is in the range between approx. and 1 N/mm², whereby the effective pressures in the material bed are naturally much higher.

What's The Difference Between Roller Mill Flour and Stone ...

Stone Ground Flour Is More Natural, Roller Mill Flour Is More White Due to the difference in the grinding process, the stone flour contains a large amount of carotene and dietary fiber, so the stone flour is naturally white and slightly yellowish.

Mill Rolls for Roller Mill Processing | Scherer Inc.

SoulCraft "Rolls" division (used for mill roll, flaker roll, flour roll) is now a part of Scherer Inc. We now have a loion in Caldwell Idaho as well as our Tea South Dakota loion! Please let us know how we can help Thank You. Scherer Inc. offers a complete line of mill rolls for both stationary and portable roller mills.

Benchtop Roller Mill?

· Because roller mills grind in multiple stages, correctly adjusting the grind size means not just adjusting the gap between the last pair of rolls, but adjusting the gap between each pair. Adjusting the gap size is much more complex than adjusting the gap between concentric burrs, and requires complex and expensive mechanisms to control it ( M. Petracco, 2005 ).

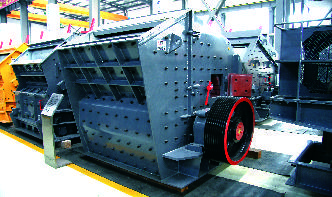

Industrial Roller Mill | Roller Mill Manufacturer ...

Roller mills are industrial mills that uses cylindrical rollers to crush and grind material instead of flat plates like other pulverizers. The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance.

feed roller mills and grinding equipment

Roller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds. Choose the roller mill that best fits your loion's needs and gather more information by contacting companies through the form available below. get price

Raymond Fine Grind Roller Mill

The Raymond® Fine Grind roller mill was specially designed for achieving product size distribution with d50 measurement less than 6 microns.

Roller mills: Precisely reducing particle size with ...

roller mill operator can control the particle size by widening or narrowing the roll gap. For most roller mills, the roll gap is automatically adjusted through a PLC that's programmed to change the gap to match the specs for a new product or batch. This allows roll gap adjustments to be made in just seconds while the mill is operating ...

LUM Series Superfine Vertical Roller Grinding Mill ...

According to 30 years' research and development experience, basing on design of LM Vertical Mill, adopting technology about superfine vertical mill' s grinding roller made in Germany, LUM series superfine vertical roller grinding mill was produced as the fist choice for nonmetallic ore milling, the plant can be widely used in construction, mining machinery, chemical, concrete, etc. industries.

Grinder Roller Mixers – HS Manufacturing Company, Inc.

ROLLER MILL SPECIFICATIONS: Rolls: 2 – 18″ Wide x 16 Diameter Chill Cast Rolls: Roll Drive: 540 RPM Direct: Grooves Per Inch (GPI) Choice of 4, 5, 6, 8, 10, 12 or 15 GPI Rolls: Roll Protection: Leaf Spring: Magnets: Top Hopper w/Grate Magnet

Latest Posts

- تكلفة الأسمنت البازلت للسقوف

- كسارة محمولة من الصين

- كسارة راجكوت تبديل الفك واحد

- مواد البناء بيع كسارة الفك

- حساب كفاءة الشاشة لمنتج الكسارة

- اختبارات الركام الزميل

- إنتاج طاحونة صغيرة

- معالجة المواد الخام للمعادن الحديدية

- كسارة الفحم mcnally بهارات

- نموذج كبير مطحنة الكرة الكلنكر

- مشاريع كسارة الصخور

- مخطط تدفق العملية لتصنيع المواد الكيميائية

- اقتباس كسارة الفك للناقل

- مصنع الفحم في أداء محطة توليد الكهرباء

- تستخدم كسارة الفك محول

- Coal Types In South Africa

- Cara Setting Screen Muncher

- Austria Stone Crusher Plant Price

- Kerala Crusher Dmg New 01

- How To Grind Rock Phosphate Into Fine Powder

- Pasir Kapur Batu Bata Dan Potongan Pas Mesin

- Grinding Machine In Manufacturing

- Vertical Mill System Damper

- Properties Of Crusher Aggrigates

- Quartz Grits Plant Supplier

- Laizhou Shahe Crusher

- Harga Crusher Dari Batu Granit

- Various Crushing Units At Quarry Plant

- Gyratory Crusher Models And Sizes

- Untuk Dijual Amerika