Hazard From Crushing Process Jaw Crusher

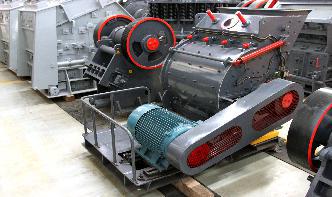

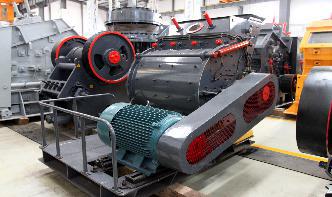

Crushing plant

Components. Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc. . Vibration Feeder: These machines feed the jaw and impact crusher .

ENVIRONMENTAL ISSUES IN STONE CRUSHERS | The .

· Primary jaw crushers produce more dust than comparable gyratory crushers because of the bellows effect of jaw and because gyratory crushers are usually chokefed, thus minimising the open spaces from which dust may be emitted. For subsequent reduction stages, cone or roller type crushers produce more fines as a result of attrition and consequently generate more dust. Emissions During .

hazards to the granite mineral processing processe

hazards to the granite mineral processing processe. Granite Processing Plant Crusher,The Granite Processing machine cylinder liners are installed in the process Avoid material circulation in the inner wall of the cylinder and quickly erode the inner wall of the wear cylinder causing operational safety hazards and fully utilize the working surface geometry and arrangement of the lining to ...

FactSheet

Crushing Machines Using crushing machines at construction sites to reduce the size of large rocks, ... operating crushers. In addition, operator isolation through the use of a remote control station or ventilated booth that provides fresh, climatecontrolled air to the operator must also be used to control exposure when operating crushers at construction sites. Photo courtesy of Screen Machine ...

Common Jaw Crusher Injuries, and How to Avoid Them

Rock crushing isn't a job for the faint of heart. Whether you are quarrying or ore processing, crushing is hard, fastpaced work that, if proper precautions aren't taken, can be dangerous as well. While the jaw crusher has become increasingly safe in recent years, it is arguably one of the most dangerous pieces of equipment at the plant. Regardless of whether you are doing ground work or ...

Effects Of Stone Crushing Plants On Environment | Crusher ...

effects of lead mining on plants – crusher for sale used .. Stone Crusher. Jaw Crusher; JC Jaw . resulted in adverse effect on plant dry matter . shri nathdwara rabha bhinder aggregate crushing plant; environmental impacts of limestone ..

Jaw Crusher

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber. This crusher produces less .

SOP Can Crushing Procedures

Ground steel drums prior to starting the crushing process: see Attachment A of SOP Waste Bulking. Crushing process. Open the door to the crusher compartment and load containers on the grate in the unit. Close the door and pull the hydraulic lever; allow crusher to complete a full cycle. Release the lever if necessary. Open the crushing unit door and remove crushed containers. Scrape ...

The Danger of Crushing Hazards in Construction

Crushing is probably one of the most common formsof injury sustained by pedestrians on a construction site. However a crush injury can occur whenever the workers body is caught between 2 heavy objects. Some of the most brutal crushing injuries occur when a worker is hit by a falling object, such as a cranes load. These loads are usually heavy materials such as steel, cement blocks etc. which ...

Crushers

CRUSHING MASTER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaws; one is fixed while the other reciproes. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their ...

Crushed Stone Processing

Processing operations may include crushing, screening, size classifiion, material handling, and storage operations. All of these processes can be significant sources of PM and PM10 emissions if uncontrolled. Quarried stone normally is delivered to the processing plant by truck and is dumped into a hoppered feeder, usually a vibrating grizzly type, or onto screens, as illustrated in Figure ...

What are the hazards of voltage instability to ore crushers

· Ore crusher is a machine used for ore crushing and processing. Common ore crushers include cone crushers, impact crushers, jaw crushers, hammer crushers, mobile crushers, and ore crushers need to pay attention to voltage during use The problem.

Industrial Jaw Crushers For Sale | Affordable Crushing ...

4. Jaw crusher. This is rock crushing equipment that is mostly used for crushing rocks and materials that have a strength of less than 320MPa. There are seven models of jaw crushers for sale available and the maximum feeding size ranges from mm and the discharge produced ranges from 10350mm. They have a high processing capacity ranging ...

Crushing and screening solutions

C Series jaw crusher as the backbone of your process. Jaw crushers ® C Series™ Uncompromised reliability and productivity The reliability of C Series jaw crushers is based on a revolutionary pinned and bolted, nonwelded frame construction. This design provides excellent fatigue strength even in toughest quarrying or mining appliions. 's foundry expertise ...

AMIT 129: Lesson 12 Crusher and Mill Operation Safety ...

Clearing blockages in large jaw crushers by remote controlled hydraulic equipment is recommended but note that this may introduce other hazards such as flying rock chips from impact hammers. Crusher and Mill Maintenance. Hazards during maintenance are many including falls, being caught in moving equipment and being crushed by heavy components. Recently an overseas operator with more than 4 ...

CrushingScreening System For Mineral Processing ...

For minerals with different properties and hardness, we can recommend suitable crusher accordingly, including jaw crusher and cone crusher for hard material, impact crusher and roller crusher for relatively soft material. In addition, for some mineral projects, the mining sites are in different loions, which is far from processing plant, and Prominer can also supply portable crushing ...

News and Stories about EmiControls and our Projects

The mechanical action of crushers can generate air movement;, jaw crushers can have a bellowstype effect. A method to estimate maximum generated airflow from this type of crusher has been described [Burton 1999] Where D = diameter of the hammer assembly from the tip to tip, feet; and W = the width of the hammers, feet.

Rock Crusher

Jaw crushers are an excellent primary crusher when used to prepare rock for subsequent processing stages. Cone and gyratory crusher. These are also compressiontype machines that crush material between a moving and a stationary piece of steel. The setting between the two pieces controls the output. Although the chamber is round in shape, the moving piece of steel is not meant to rotate ...

Jaw Crusher Working Principle

· The jaw crusher is not so efficient a machine as the gyratory crusher described in the next paragraph, the chief reason for this being that its crushing action is confined to the forward stroke of the jaw only, whereas the gyratory crusher does useful work during the whole of its revolution. In addition, the jaw crusher cannot be chokefed, as can the other machine, with the result that it is ...

Crushing and Screening

· Hydraulic grizzlies help crushing operations become more efficient when handling large material at the beginning of the crushing process. But what is often overlooked is how they also contribute to the overall safety of the plant. Because the grizzly removes larger unwanted material from reaching the jaw, the probability of plugging a jaw is reduced. For workers, unplugging a jaw is very ...

Rock Crushing Process | Crusher Mills, Cone Crusher, Jaw ...

Rock Crushing Plant,Rock Crusher Plant,Rock Crushing .. Rock crushing plant Process: First, garbage are delivered to the vibrating feeder through hopper, they may be fed into rock jaw crusher evenly and continuously.

Assesment Of Health Hazard Associated With Stone Crushing

MJ Series Jaw Crusher. MJ series jaw crusher is mainly used as a coarse crushing crusher. Its purpose is to crush rocks into smaller particle sizes for subsequent processing. Read more. MC Series SingleCylinder Hydraulic Cone Crusher. MC series single cylinder hydraulic cone crusher is used in secondary and fine crushing operations. It is widely used in metallurgy, construction, highway ...

Latest Posts

- كسارة مخروطية cfbk

- أنظمة كبح غبار الكسارة المتنقلة

- sa مورد مطحنة الكرةالسعودية

- كسارة الحجارة في بلغاريا

- سعر معدات كسارة الحجر في ليبيريا

- محطة التكسير والفرز المتنقلة

- معالجة الصخور ه المصنعين quipment في الصين

- المصنعين حزام ناقل في البنجاب

- معدات تكسير الحجر للإيجار في الإمارات

- تستخدم مصنع غسل الذهب

- خط معالجة تعدين خام الحديد

- خصائص رمل التعدين في الخرسانة

- الشركة المصنعة لمعدات التعويم

- بليك الفك سعر كسارة في المملكة العربية السعودية

- مصنع مطحنة الكرة الاسمنتية

- Process Of Sampling Aggregate

- Lead Zinc Mine Grinding Mill

- Soapstone Processing Crusher

- As A Mill Ore Concentrate Works

- Dry Magnetic Drum For Iron Ore

- Mine In South Africa Crusher

- Mill Digunakan Palu Batu

- Pfeiffer Roller Mill Grinding Plate

- Vibratory Bowl Feeder Shanghai

- Ferrexpo Poltava Mining Iron Ore Expansion Fpm 10x

- Lowongan Kerja Berau Coal Juni 2020

- 100 Tph Stone Crusher Manufacturer In Guinea

- Konsentrat Bijih Besi Pengental

- New Svadela Cone Crushers

- Grinding Mill Manufacturer Cirebon