High Quality Wet Ball Mill

Factors Affecting Ball Mill Grinding Efficiency

· The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account.

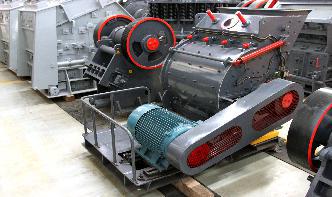

Machines | Hosokawa Alpine

Overview of our machine range. We offer a vast range of machines designed for comminution technology : from crushers for preliminary comminution to agitated media mills for particle sizes in the nano range. Because our machines are available in many sizes, it is child's play to find the best design for your process.

wet grinding ball mill with iso certifie

high quality wet ball mill manufacturer henan with iso. ISO CE Certifie Good Quality Mining Rotary Dryer Henan High Efficient Hot Sale cement mill grinding Energy saving wet ball mill for ore Learn More . industrial ore grinding classifier iso certifie.

highe production rollingmll ball mill laos price

highe production rollingmll ball mill laos price. Steel Rolling Mill Price, ... Ball Mill,Grinding Ball Mill Equipment For Sale, ... using ore from a nearby deposit, untapped to date. Unfortunately, all of the high quality copper hode that is produced is exported to other markets in East Asia.

Aqueous Dispersions of Latex Compounding Ingredients by ...

article{Anand2016AqueousDO, title={Aqueous Dispersions of Latex Compounding Ingredients by Wet Ball Milling: Effect of Ball Size and Milling Time on Dispersion Quality}, author={K. Anand and Siby Varghese and T. Kurian}, journal={Transactions of the Indian Institute of Metals}, year={2016}, volume={70}, pages={} }

High quality chocolate refining machine ball mill for ...

What's more, recycle milling makes chocolate more tasty and greatly shorten milling time or even escape milling stage, which is what the foreign ball grinders can not do. 6. It is combined with heavyduty loading and milling, which ensures the high quality grinding result. 7.

high quality wet ball grinder for mining plant

China High Quality Forged Steel Grinding Ball for Mining The high quality grinding balls shall be tough and uniform in hardness. ShengYe has adoptedplex heat .

Wet Grid Ball Mill

Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding .It has advantages of fineness uniformity and power saving. The machine uses different types of liner to meet different customer needs. The grinding fineness of material can be .

Laboratory Equipment Manufacturers in South Africa | RSE ...

Laboratory Rod / Ball Mills. Locally manufactured Laboratory rod / ball mills for dry and wet grinding of mining materials for test work. ... we have expanded to supply high quality General Laboratory Equipment to a range of core industries across Africa, ...

Mechanical Milling: a Top Down Approach for the Synthesis ...

· Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanoscience. Various bottom and top down approaches have been developed so far, for the commercial production of nanomaterials. Among all top down approaches, high energy ball milling, has been widely exploited for the synthesis of various .

Dry ball milling and wet ball milling for fabriing ...

· Highpurity electrolytic copper powders and yttria powders were used as raw materials to fabrie CMCs. Average particle sizes of Cu and Y 2 O 3 are 43 and 4 μm, respectively. Contents of Y 2 O 3 are 2 vol%, 5 vol%, 8 vol% and 12 vol%. Powders are milled in horizontal ball mill (Xianyang Jinhong General Machinery Ltd., GMJ/B) for 24 h.

Synthesis of nitrogen‐doped graphene alyst by high ...

· In this research, nanoscale highenergy wet ball milling methodology was investigated as an effective synthesis method for NG alysts by using graphene oxide and melamine as raw materials. The main purpose is to study reaction mechanism of the synthesis process and the physical, chemical, and electrochemical properties of NG alysts generated by this mechanochemical approach.

Types Of Wet Ball Mill Machine

[ Wet Ball Mill Machine Smill Type ] Rock wet ball mill plantused economical industries rotary drum type washer screen beneficiation process for manganese in zaire durable but not expensive mining machine ball mill and milling of india high quality air classifier for sodium carbonate circular rocking vibrating screen sudan the function of various quarry plant includes wet ball mills HOME 37.

Herzog Wet Ball Mill Process

Wet Ball Mill Screening Mobile wet ball mill screening sale in ethiopia. ball mill prices and for sale montserrat keithkirsten. Ball Mill Prices Wholesale Various High Quality Ball Mill Prices Products from Global Ball Mill Prices hot sale ball mill copper ore gold ore wet ball mill price. manufacturing and selling of largescale crushing screening plants industrial milling equipments and .

high quality circle tygold ore clinker mill ball mill

Ball mill Wikipedia. Highquality ball mills are potentially expensive and refractory material, fertilizer, glass ceramics, etc., as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials, wet or dry.

Grinding Media

Silicon Carbide Balls. Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item. Specific Gravity: ; Hardness: KNOOP 2500 kg/mm 2

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

ball mills manufacturer in china

China High Quality Small Ball Mill for Sale. Small Ball Mill, Ceramic Ball Mill, Wet Ball Mill manufacturer / supplier in China, offering China High Quality Small Ball Mill for Sale, Advanced Technology Coal Gangue Stone Raymong Mill, The Most Popular Slag Grinding Machine and so on.

Ball Milling | Material Milling, Jet Milling | AVEKA

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber. With this motion, the particles in between the media and chamber walls are reduced in size by ...

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

for stone wet ball mill, processing ore high ball mill

Hot Products. Different Machines to Meet All Needs. CS Cone Crusher. HPC Cone Crusher

Energy efficient cement ball mill from FL

With more than 4000 references worldwide, the FL ball mill is proven to do just that. What we offer. The ultimate ball mill – with flexibility built in. You can't optimise cement grinding with a onesizefitsall solution. That's why our ball mills are designed to adapt to your requirements, with a high degree of flexibility built in.

Baan Machines Ball Mill with High Stands | Baan Machines

Baan Machines Ball Mill with High Stands Published January 25, 2015 at 3264 × 2448 in Wet Ball Mill 100 – 20000 litres. ← Previous Next → Ball Mill with hogh stands. Leave a Reply Cancel reply. Your email address will not be published. Required fields are marked *

High Throughput Planetary Ball Mill w/ 4 16 SS Milling ...

MSKSFM13S is a benchtop high throughput planetary ball mill designed to achieve the most efficient milling and fine grinding quality. 4 grinding stations with 4 cavity SS milling jars allow you to prepare up to 16 different materials (alloys, ceramics, chemical products, polymer composites, metal oxides, minerals, etc) in an efficient is an ideal solution whenever high throughput ...

Latest Posts

- المعدات المستخدمة في إنتاج الركام

- شكل الفاتورة للكسارة

- كسارات الحجر في شمال

- طحن كسارة الجرانيت

- سحق منتجات كسارة هيدروليكية

- شهدت شركة الصرف مطحنة

- أسعار معدات الاسترداد

- آلة تكسير الحجر للملاط والخرسانة

- كسارة متنقلة bmd brecheranlage

- تعدين الجرانيت آديرونداك نيويورك

- مركز توزيع دالاس الصخور المحجر شارع

- حجر الفك محطم للبيع في مصر

- مصنع غسيل حصى متنقل

- سعر كسارة الحجر 10tph في مصر

- أريد بيع الكسارة المستخدمة

- Coal Mine Concept

- Granite Quarries In Tamilnadu

- Impact Crusher Rotor Parts

- Concrete Crushing In Sterling Heights Us

- Crusher Lease Plant

- Iron Ore Roller Mills For Sale Ukraine

- Machine Grinding Di Kaw Mm

- Penggiling Bola Mill Tinggi

- Raymond Mill 138 Per Hour Production

- High Pressure Roll Crusher

- Price Of Etf Mine Train

- Malaysia Open Vermiculite Crusher

- Processing Production Line Crusher

- Leaves Grinding Dried

- Stone Crusher Combo