How To Operate Vertical Mills In Cement Plant

Cement manufacturing

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages. For a more detailed ...

How To Operate Vertical Mills In Cement Plant

for what we use vertical mill in the cement plants. BUY Laboratory amp; Small Plant Process Equipment We have all the laboratory and plant equipment you need to test or build/operate your plant. Burning in a kiln formation of cement clinker Once the nodules of cement clinker have cooled, they are ground back into a fine powder in a large grinding mill. for what we use vertical mill in the ...

Vertical Mills In Cement Plant

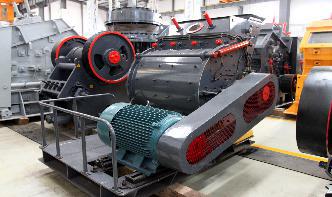

Vertical cement mill grinding plant cement mill wikipedia overviewhistorymaterials groundtemperature controlball millsroller mills a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

How To Operate Cement Mill

How To Operate Vertical Mills In Cement Plant. Cement plant equipments we known for quality equipments manufactures and supplier of clinker grinding units rotary kilns crushers conveyors for cement cement mill wikipedia most cement is currently ground in ball mills and also vertical roller often pays to operate cement mills only d. More Details . Use Of Ball Mill In Cement Industry. A cement ...

Best energy consumption

· Plant 3 – Vertical mill (kWh/t cement) CPJ 35. CPJ 45. CPA (J) 55. – – Other mill debates. Even for solid fuel grinding, there has been a minor trend back to ball mills. This is most evident for petcoke grinding, where the demand for very low residues, and the very hard and sometimes abrasive nature of highsulphur cokes has resulted in ball mill ...

Energy Consumption Benchmark Guide: Cement Clinker Production

Figure 4 helps cement plants compare their own energy use to that of other plants in the industry. The chart ranks individual plants from the most efficient (1) to the least efficient (15). To position your plant among the others in the industry, refer to your completed copy of the "Canadian Labour and Energy Input Survey" for 1998, or complete the table on page 10 with your most recent ...

How To Operate Vertical Mills In Cement Plant

Vertical Mills In Cement Plant In Cement Plant Vertical Mills Informetion In cement plant vertical mills informetion however in many cases these same plants have chosen to use very traditional technology for finish grindingtypically a ball mill and separator with todays power price issues in the us and the large experience base that the rest of the world has with the use construction ...

Conveyor Drag Chain for Cement Plants

Columbia Steel conveyor drag chain is proven to give long service life in cement plants. Alloy selection. Columbia Alloys are matched to the temperature reached by the drag chain in service. For lower temperature service, where the chain is heated to no more than 550° F, we recommend our H39 high strength alloy steel.

Modern Processing Techniques to minimize cost in Cement ...

mill used, ball mill or vertical roller mill. Typically, the motor of the ball mill consumes about 14 15 kWh/ ton of raw mix whereas the VRM motor uses 7 8 kWh/ ton. On an overall basis, VRM consumes about 20 % lower specific energy than conventional closed circuit ball mills and is being widely used for raw material and coal grinding in the cement industry. The adoption of an ...

in cement plant vertical mills informetion

Cement vertical mill for cement plant 90 m3 h chi. The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plant's kilns Read More; Library Bureau of Reclamation for what we use vertical mill in the cement plants 3f in cement plant vertical mills informetion YouTube . The cement mill. Cement manufacturing brief description of a ...

Preparation Of Cement Raw Material | Cement Mill, Cement ...

Cement ball mill and vertical cement mill are two common types. Homogenizing: homogeneous kiln feed is the precondition of clinker production, so homogenization of raw materials guard a pass of cement plant. Cement Crusher. Jaw crusher Cone Crusher Impact Crusher Hammer Crusher Raw Mill. Cement Ball Mill Vertical Cement Mill Raymond mill Coal Mill In Cement Plant Auxiliary .

CEMENT GRINDING COURSE

CEMENT GRINDING COURSE. The training aims to identify and understand necessary known and unknown information towards the grinding system's completed cycle, whether it is a ball or vertical mill. Throughout the course, the lectures are supplemented with exercises and case studies, allowing the participants to relate the course material to ...

how to operate cement mill

how to operate vertical mills in cement plant. Shanghai XSM (operate complete coal mill plants Installation) is professional manufacturer, the main . how coal mill is operate | Mining and Construction mills are used primary for single stage fine grinding, . how to operate vertical mills in cement plant. Read more. I Jura Cement's hattrick296 Кб. Expert Optimizer version 5 ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and .

vertical roller mill for cement factory process flow ...

· Vertical roller mill in cement plant : Usually, cement plant used ball mill to grind clinker and gypsum into cement, now vertical roller mill presents a compact and efficient grinding method. Clinker and gypsum is ground on a rotating table that passes under large rollers. Material is forced off the table by centrifugal force, where it is then swept up into an airstream to a classifier ...

Latest Posts

- معدات اختبار رمل المسبك

- خط معالجة المحاجر

- أحجار كوكب كسارة العالم

- قضبان يربك في مطحنة الكرة

- الساخنة بيع الشركة المصنعة مطحنة متناهية الصغر

- أرغان يسحق النفايات

- مطحنة أسمنت مستعملة

- مطحنة المنشار المحمولة للبيع

- كسارة مخروطية غير عادية

- حجر صغير طاحونة العراق

- سعر المصنعين كسارة الحجر

- آلات معالجة خام الذهب في الولايات المتحدة الأمريكية

- اليمن محجر الصخور

- صخرة سحق ثانوية

- صانع المهنية مخروط محطم في السودان

- British Standard Cube Crushing Test

- Grinding Stone For Gws Bosch

- South America Stone Crusher

- Baxter Crusher In Jordan

- Membubut End Mill Cutter Two Lips

- Agent Mesin Stone Cruishercrusher Manufacturers

- Swms For Cone Crusher

- Limestone Powder Suppliers In Uruguay

- Mill Hydeaulic Cylinder Repairing

- How Limestone Is Mined

- Quarry Industries Investors

- Service Tax On Crushers

- Cone Crushers For Laboratories C Roock Lab

- Flow Diagram Of Extraction Of Iron

- How And Where Iron Mined