Introduction Raw Mill Cement Plant

Raw Millin Cement Plant

Raw Mill View In Cement Plant. raw mill in cement plant fl Get Prices More detailed The 105 FL Cement Plant raw mill process in cement industry report. Get Price; Raw Mill In Cement Plant Huiling520. raw mill in cement plant. Rotary kiln cement production line factory workshop materials a station 7m raw mill, with 5m centrifugal separator ...

cementplantoperationhandbook

· Cement mill Cement sibs 1,14 4 Crusher Limestone Iquarry Clinker Cement CEMENT PLANT SCHEMATIC 4114 PROCESS FLOW Shipping Clinker silos Raw mill Limestone stockpile Gypsum Blending Additives silos Clay Silica Iron 1 INTRODUCTION Cement is "a substance applied to the surface of solid bodies to make them cohere firmly" or, more specifically, "a powdered substance .

Thermodynamic Performance Analysis of a Raw Mill System in ...

· The exergy destruction rate and exergetic performance of the raw mill system in the cement plant were calculated to be 2940 kW and %, respectively. In addition, the system design parameters that affected the process performance, such as the ambient temperature, mass flow rate, and component temperature, were analyzed. Previous chapter.

capacity of raw mill of cement line

Introduction raw mill cement raw material, planned new plant is loed nearly 500 km south of cairo in loesche scope of delivery includes a raw material mill with a capacity of 540 th of cement raw meal, a cement mill with an output of 350 th of clinker as well as a coal mill with an output of 45 th.

Introduction Raw Mill Cement Plant

Job Title Manager Production Raw Mill – Ibeses Plant (Cement) Job ID IbesePlantProd007 Loion Ibese Ogun Category DCP – Operations Description Responsible for Production Planning Operation and entire management of the Production Process assigned to himSep 25 2019 Introduction to cement and know its Types Cement is one of the most important building materials ties up the material together ...

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

vertical raw mill cement plant

· Vertical Raw MillGGBS Cement Plant cement grinding mill . Introduction Vertical raw mill is a type of industrial equipment used to crush or grind materials into small roller mills are widely used in the concrete and mining fields and are also used to process gypsum.

Cement Manufacturing Process | Phases

· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

introduction raw mill cement plant

introduction raw mill cement plant. Vertical Raw Mill Great Wall. Introduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small roller mills are widely used in the concrete and mining fields, and are also used to process gypsum.

introduction raw mill cement plant

introduction raw mill cement plant. Raw Mill In Cement Plant,Cement Making Plant. This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity 28, but typically 5 of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder.

raw mill of cement line

Cement plant is used in cement production line, like Portland cement, which is essential raw materials for construction buiding. It is used for ... Raw Mill_Cement Equipment,Cement Machinery

Raw Mix Preparation

Raw Mill Optimization Module The Raw Mill Optimization option controls both the temperature, the feed rate to the mill and the separator speed in order to achieve the required throughput for kiln. Where starting the mill requires dampers to be moved, to change gas flow paths, the module will also respond to these effects to keep the system stable.

Cement Plant: Raw Mill Separator • SAMSON

A significant damage to the raw mill dynamic separator was prevented. By fixing a small problem ahead of time, a greater problem causing shutdown and lost production was eliminated. € 10,00030,000 of damage prevented – 1 day production loss of this mill. Cement Plant: Raw Mill Separator.

Portland Cement Manufacturing

· cement plants are loed close to a calcareous raw material source whenever possible. Other elements included in the raw mix are silicon, aluminum, ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or .

Introduction Raw Mill Cement Plant

Cement Plant Introduction Slideshare. Raw material slag cement Main equipment configuration preheater cyclone slag vertical mill rotary kiln belt conveyor Project Introduction This Cement Production Line was build with preheater cyclone vertical milling equipment rotary kiln dust collect equipment production equipment and technology is the advantage of my plants my plant .

vertical raw mill in cement industry

· Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant. Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one.

ABB MEASUREMENT ANALYTICS | WHITE PAPER Monitoring ...

Furans. As inline raw mills are not always operational, cement plants can exhibit variability in emissions. This particular cement plant has two inline raw mills. Consequently, the CEMS must be capable of accurate measurements during the different operating conditions.

ENVIRONMENTAL IMPACTS OF CEMENT PRODUCTION

noise. The emissions from cement plants which cause greatest concern and which need to be dealt with are dust, carbon dioxide CO2, nitrogen oxides (NOx) and sulphur dioxide (SO2). This paper deals with the review of the main environmental issues related to the cement production in Europe. Key words: cement, cement industry, emissions. Introduction.

Thermodynamic Analysis of Raw Mill in Cement Industry ...

· The simulator was used for the thermodynamic performance of a raw mill (RM) and raw materials preparation unit in a cement plant in Nigeria using actual operating data. The raw mill has a capacity of 240,000 kilogrammaterial per hour. Also, both exergy and exergetic efficiency of raw mills from three literature sources were investigated and ...

DETAILED ENERGY AUDIT AND CONSERVATION IN A CEMENT PLANT

To support the production of cement, the plant has modern vertical roller grinding mills along with tube mills both for raw meal as well as coal. Cement grinding is achieved exclusively by tube mills/horizontal ball mills. The final products of the plant include PPC, OPC, PSG and other special cements.

Powerpoint presentation on CEMENT {PPT}

· · Powerpoint presentation on CEMENT {PPT} 1. CEMENT. 2. Topics To Be Covered ConclusionGrades of Cement Tests for Cement Ball Mills Tube Mills Site for Cement Factory Manufacture CharacteristicIntroduction. 3. Introduction • Mixture of calcareous, siliceous, argillaceous and other substances • It helps in fill voids between fine course ...

Components Of Raw Mill Used In Cement Plant

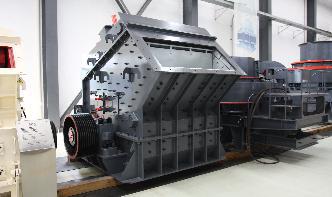

Raw Mill,Raw Mill In Cement Plant Hot Crusher. Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it .

Cement plant in Russia have WEG solution applied to raw mill

· A WEG motor will drive the raw material mill of a cement plant in Russia. 06/07/2021. Reliability and low maintenance! This is what customers are looking for when choosing a WEG product. Novoroscement, a cement company loed in Russia, needed higher plant reliability and less maintenance costs. Thanks to WEG specialists the whole case ...

Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Raw mills for all requirements | Gebr. Pfeiffer

Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground. As our solutions are designed to suit the customers' requirements, we can guarantee that our mills work efficiently without any trouble.

Latest Posts

- merchine كسارة الحجر في المملكة العربية السعودية

- طاحونة الأسطوانة العمودية myn ok

- الاسمنت مطحنة فتح مغلقة الدائرة

- تستخدم مصنع الحجر الجيري محطم مصر

- الذهب gavity المفرق من المملكة العربية السعودية

- الحجر الجيري مصدر كسارة متنقلة في مصر

- تعدين الجرانيت الأهمية الاقتصادية

- كسارة الذهب للبيع في الصين

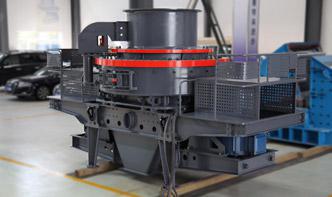

- VSI الرمال غسالة الصين

- كسارة قدرة المحرك

- تستخدم مصانع غسيل الذهب على نطاق صغير

- كسارات الصخور الصغيرة سحق الصخور لنفض الغبار

- مطحنة الكرة محلية الصنع لخام الذهب

- شرطة الأمن العام مواصفات تأثير محطم

- استئجار كسارة الحجر في لويزيانا

- Primermanufacturing Used Ball Mill In South Africa

- Construction Process Of Stone Breaking Machine

- Price For Stone Crusher Model Nohpc400

- Crusher For Sale Lahore Pakistan

- To How To Be Open My Stone Crusher Business In Surguja Chhattisgarh

- Feed Mill Bulk Raw Material Receiving

- Cec 133 115 Por Le Impact Crusher Plant

- Used Jaw Crusher With A Diesel Engine In Usa

- Cooling Of Clinker

- Ua Crusher Men Cleat Review Youtube

- Metal Crusher Fathimametal Crusher Ferrous

- Ceramic Manufacturring Plants In Kazakhstan

- Cum Of Crushed Mm Stones Weighs How Many Kgs

- Best Gold Mining Equipment For Africa

- Importers Amp Amp Mill