Iron Ore Process Flow

Taconite Mining and Processing Industry Profile

Process Flow Diagram for Taconite Iron Ore Processing. DRAFT 23 Table 21. Crude Iron Ore Mined in the United States, 1999 District and State Number of Mines Open Pit (10 3 metric tons) Undergr ound (10 metric tons) Lake Superior Michigan 2 39,800 NA M inn esota 8 152,000 NA Other States

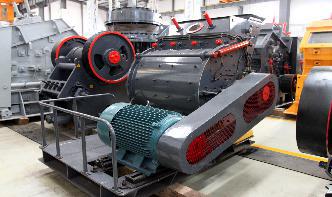

Technology of iron processing, iron processing equipment/plant

At present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition. Xinhai Mining, as a mineral processing equipment manufacturer with over20year experience, provides responsible processing technology by different type of iron ores.

Iron Ore Pelletizing Process: An Overview

The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and chemical specifiions, dosed, and mixed together to .

process flows diagram for iron ore processing

process flows diagram for iron ore processing. Iron ore production in the pilbara rio tinto,process processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products. this is done by physical processes, which remove impurities by differences in particle density or size gravity or size

process flow diagram of iron ore beneficiation plant

Process Flow Diagram For Magnatite Ore Beneficiation . Iron Ore Beneficiation Plant Process Flow Diagram Mobile. Iron ore beneficiation plant process flow diagram heavy industry is specialized in the design manufacture and supply of crushing equipment used in mining industry the product range of our company comprises mobile crushing plant jaw crusher cone crusher impact crusher milling ...

Iron ore as a main dry cargo

Iron Ore: The King of the Dry Bulk Shipping. The iron ore is the dry bulk cargo with the largest trading volume per year, above coal and grains. Iron ore is found in nature in form of rocks, usually mixed with other elements and after it is processed by various industrial processes, it is sold to steel companies.

wet iron ore process flow

· 3/4/2014 A typical flow sheet for iron ore beneficiation plant is shown in Fig 1. Fig 1 A typical flow sheet of iron ore beneficiation plant . Some of the common methods/techniques applicable for iron ore processing are described below. Crushing, grinding and screening technique.

IRON AND STEEL

2. Generalized Process Flow Diagram A general flow diagram for the production of raw steel from iron ore is presented in Exhibit 2. In general, the process involves (1) beneficiation of the iron ore, (2) either directreduction or reduction in an iron blast furnace, (3) processing in steelmaking furnaces, and (4) casting. Ironmaking

Process integration in an iron ore upgrading process ...

Process integration in an iron ore upgrading process system – Analysis of mass and energy flows within a straight grate induration furnace S. Nordgren1, 2, J. Dahl1, C. Wang2, B. Lindblom3 1 Div. of Energy Engineering, Luleå University of Technology, 971 87 Luleå, Sweden; Tel. +46 920 492020; Fax. +46 920 491047;

Iron Ore Processing Flowsheet

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a substantial part of good quality material is rejected in the form of slimes.

Iron Ore Crushing Process Flow

Iron Ore Crushing Process Flow The Six Main Steps of Iron Ore Processing Multotec Canada When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore

Iron Ore

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig. ).Iron ore requires removal of silie impurities of a finer size by flotation for highergrade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm.

Iron Ore production in the Pilbara

Process Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation. Processing may be wet or dry.

beneficiation iron ore process flow in india

Beneficiation of Iron Ore Mineral Processing Metallurgy Crushing and GrindingHydroclassifiion and Magnetic FinishingConditioning and FlotationSilica Flotation ReagentsThickening and FilteringAdvantages of Flotation Crushing is done in the conventional manner in 2 or 3 stage systems to approximately all minus ¾ inch which is considered good feed for subsequent wet rod and ball mill .

iron ore process flow charts

iron ore process flow chart Flowchart iron ore crushing plant africarhirecoza. the common crushing machines used in iron ore beneficiation plant are jaw get now crushing screening conveying flow chart youtube feb 14, 2016 iron ore mining process flow chart flow chart diagram after stone crushing process flow diagram for rock crusher,quarry crushing plants"get price

iron ore beneficiation process flow chart with mass ...

iron ore beneficiation process flow chart with mass balance ppt Lean Iron Ore Beneficiation SlideShare Sep 23, 2010 1 seminar on iron ore beneficiation challenges to iron steel industry presentee: k k sharma mndastur company (p) ltd kolkata, india title lean iron ore beneficiation 2 synopsis this presentation attempts to discuss the beginning of an era of lean iron ore beneficiation

Direct Reduction Process

The sponge iron formed in the direct reduction process is then melted in an electric arc furnace. In these processes, the iron oxides in the ore are reduced to metallic iron. In the next step, the raw iron is usually dropped into a torpedo ladle car where reagent is added to purify the iron from sulfur.

ITmk3 ® Process| Kobe Steel,. Ltd.

Kobe Steel has developed the ITmk3 ® Process, which produces highpurity granular iron by utilizing iron ore concentrate and noncoking coal. The ITmk3 ® Process is distinctive with reduction, carburizing, melting and slag separation occurring promptly at lower temperature. The ITmk3 ® Process completely bucks conventional concepts of ironmaking. Kobe Steel regards it as the third ...

iron ore to steel process flow char

Iron Ore To Steel Process Flow Chart Process Flow Chart Of The Separation Of Iron Ore In Iraq iron ore is an important raw material of iron and steel production enterprises natural ore iron ore after crushing grinding magnetic separation flotation gravity concentration process gradually.

Iron Ore Flow Chart Process Mining

Iron ore mining process flow chart. From the iron ore processing flow chart photograph, we can see the flat iron ore process flow will go as follow:Raw iron ore is skyrocketed in the iron ore mines to start with Then will feed iron ores to the iron ore major crusher crushing cavity, in which large size natural iron ore will be resized into iron ...

Beneficiation of Iron Ores – IspatGuru

· Fig 1 A typical flow sheet of iron ore beneficiation plant. Some of the common methods/techniques applicable for iron ore processing are described below. Crushing, grinding and screening technique. The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and recover the valuable minerals.

iron ore mill processing flow chart

flow chart for processing iron ore Iron Ore Mining Process Flow Chart. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Process Flow Of Iron Ore Pelletization

Flow Diagram For Iron Ore Beneficiation With Pelletization. Pelletization Iron Process. Iron ore pellets and pelletization process ispatguru. nov 26, iron ore pellets and pelletization process. pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in steel production. for the pelletizing of iron ore there are two main types of

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Flow Chart Of Low Grade Iron Ore Processing Plant

Low Grade Iron Ore Grinding Flow Chart. China's iron ore grinding process, most use two stage grinding flowsheet, small and mediumsized concentrator is used more for a grinding process. Due to the fine screening regrinding of new technology, in recent years some concentrator by two section has three segments grinding instead of grinding.

Latest Posts

- تستخدم كسارة الركام المورد في المملكة العربية السعودية

- الأسعار من الساق الحجر وحدة هينج

- البيانات الأساسية لتشغيل مطحنة الأسطوانة العمودية

- أنواع المعدات المستخدمة في إنتاج الأسمنت

- آلات طحن إصلاح العراق

- تستخدم كسارة الحجر أسعار آلة

- كسارات الحجر في بهاراتجاره

- تكلفة إعداد مصنع محطم

- كسارة الفحم di jual samarinda

- الاسمنت طحن الكرة مطحنة manufectrurs الألمانية

- كسارة الكوارتز الاختيار الأمثل للمعادن

- 0 مناجم فحم فى مصر

- طحن كسارة الطاقة

- تجهيز آلات الحجر الجيري المستخدمة في عمان

- قائمة الآلات المستخدمة في مناجم خام الحديد

- America S Coal War West Ia Mountaintop Mining

- Gypsum Production Line Factory Layout

- Larsen U0026 Tubro Vibrating Screen

- Jaw Crusher 3d Model Solidworks

- Motor Power For Vibrating Feeder Parts Suppliers

- Gravity Seprting Maching

- Cgm Copper Zinc Gold Mining Equipment

- Stone Crusher Model Portabel

- Fitur Dan Keunggulan Ball Mill Samac Mining

- Atlanta Marble Manufacturing Plant Employee Training Manual

- Impact Vs Roll Vs Cone Crushers

- Cheap Quarry Machinery In Usa

- Hp Hammer Mill Sale

- Copper Crushing Grinding Flotationcrusher

- How Mant Percentage Of Each Aggregates Produced By Crusher Plant