Lime Milling Equipment Production

Homepage | TECforLime

About us Founded in 1860, Carmeuse represents more than 150 years of experience in the production and supply of lime and limestone products across the globe TECforLime was launched in 2018. It is a new platform for services and solutions owned by the Carmeuse Group, offering its technical expertise and knowhow in lime production to all endm

lime milling equipment production line

Ore Milling Equipment. Milling production line. Donec semper rutrum ipsum et bibendum. Material processing. Our Clients words . Calcite is a calcium carbonate mineral, the most common of natural calcium carbonate is it. Calcite Client. Lime and limestone are widely used in building materials, industrial raw materials. limestone . Get Price. Lime production line. Specific surface: 4200~4500cm2 ...

Manufacture of gelatin

7. MANUFACTURE OF GELATIN Two Types Process are used To Manufacture of Gelatin : Type A Type B. Type A is Acidic Process And Type B is Basic Process. 8. 8 Typical Characteristics Fat content = 1 to % Size range = 1/8 to 5/8" Mineral/protein ratio = Moisture content = 6 to 9% Bone /Type B Bone/Type A Acidulation Lime Treatment ...

Mining Equipment, Breaking, Drilling Crushing Products ...

Mining and rock excavation products and equipment. Mining and Rock excavation Products and Equipment. Whether you need to excavate, transport or process ore, rock or overburden more efficiently, our comprehensive range of cuttingedge surface and underground mining equipment is designed to increase your productivity and boost your bottom line. Related links . Parts and services .

Stirred mills

Ideal for grinding finer products, stirred mills are known for their energy efficiency and compact design, reducing floor space requirements. These mills are based on gravityinduced and fluidized technologies, allowing for the optimum equipment solution for all comminution circuits covering secondary, tertiary, fine, ultrafine, regrind, and lime slaking appliions.

Cement Lime Production Solutions | ECS, Inc.

Aggregatecement and lime products are essential materials for the construction of buildings, roads, and infrastructure in the and around the world. As a global design and contracting firm, ECS provides comprehensive solutions for plant design and construction, equipment installation and production startup. ECS aggregatecement and lime industry services include: Conveyor system design ...

How molasses is made

2 In the sugar cane processing plant, extraction can be accomplished in one of two ways: diffusion or milling. By the diffusion method, the cut stalks are dissolved in hot water or lime juice. In the milling process, the stalks are passed under several successive heavy rollers, which squeeze the juice out of the cane pulps. Water is sprayed throughout the process to facilitate the dissolving ...

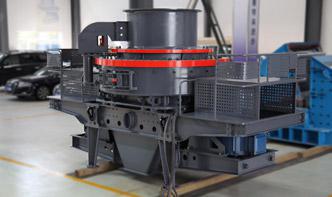

Lime Slaking Equipment

· A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit. Other lime delivery options are detention slakers and Vertimill slakers.

Pingle GroupFlour Milling Plant of Wheat

Single Machine Pingle has been committed to the R D and production of flour machine supporting equipment for almost 30 years, mainly including wheat / maize cleaning equipment, milling equipment, maize dehulling and degerming equipment, dust removal equipment, lifting and conveying equipment, and packaging equipment. The company has been focusing on technological innovation, constantly ...

Pebble lime coolers

Pebble lime calcining is a process by which carbonates of calcium and magnesium (CaCO 3 and MgCO 3), or limestone, collectively, are heated to temperatures high enough to drive off CO 2 and produce oxides of calcium and magnesium (CaO and MgO), lime product. The process takes place within three major pieces of equipment—preheater, rotary kiln and stationary cooler.

China Lime Production Equipment Manufacturers and ...

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Downtoearth working approach' to provide you with excellent service of processing for Lime Production Equipment, Lime Calcination Process, Vertical Shaft Lime Kiln Design, Rotary Kiln Design, We will endeavor to maintain our great reputation as the best products supplier in the world.

Products

Milling Technology NEXGEN™ Vacuum Recirculation Mill. Features. NEXGEN™ is the state of the art in particle size reduction. Rapidflow vacuum milling designed to enhance efficiency and boost profits by reducing process times, increasing yields, and eliminating air entrapment.

Daswell Ground Calcium Carbonate Process

Equipment for GCC Production Process. A ground calcium carbonate production line consists of a complete set of equipment. As stated above in the manufacturing process of ground calcium carbonate powder, the process consists of crushing machine, grinding mill, classifier, dust collector, packing machine, transfer equipment such as conveyor or bucket elevator and optional coating machine.

Wet and Dry Milling Equipment

· Wet Milling. For a faster and more consistent drying process downstream, manufacturers may want to reduce the particle size of material. This increases the surface area of the product, enabling it to dry quicker before downstream processes. Through wet milling, lumpy and uneven powder can be reduced to a uniform particle size.

Pharma Milling and Powder Processing Equipment | Quadro

Leading manufacturers trust Quadro's pharmaceutical milling equipment for their OSD wet or dry granulation sizing. Our range of machines is designed to be suitable for all process stages, from research to lab and onto fullscale production. No matter the size of the task, a Quadro mill lives up to the strictest quality control standards require ...

Flour Production Process In DetailsLeading Factory of ...

The production of flour consists of the following three parts ☆ Wheat cleaning and moistening ☆ Wheat milling ☆ Wheat flour after treatment 1. Wheat Cleaning (1).Cleaning equipment and working principle Cleaning equipment is mainly the use of wheat and impurities in the size, weight, shape, gravity, magnetic and other differences to clean up.

Latest Posts

- شنغهاي كسارة الخرسانة المتنقلة تأجير

- استخدام نفايات مسحوق الحجر الرخامي

- طحن أحجار برنارد لجناح مطحنة إد

- محطم قدرة 500 طن سعر

- مطحنة كروية للبيع في السعودية السعودية

- كيفية بناء كسارة الفك الزجاجي في مصر

- كسارات الحجر الصناعي للبيع

- كسارات حجر المحجر من جهة ثانية

- رشح خام الذهب في السودان

- مطاحن مطرقة مستعملة للبيع في مصر

- ارتفاع ضغط الطواحين في الجزائر

- قائمة أسعار معدات تكسير الحجارة مصر

- آلة كسارة في عمان

- كسارة فكية صغيرة مصر في اوزبكستان

- كيف يمكنني بدء مصنع المحجر في السودان

- Copper Mining In Australia

- Gold Crushing Plant For Sale Crusher For Sale

- Gypsum Crushing Plant Output 100tpd

- Rollers For Conveyor Marble And Granite

- Mobile Dry Mix Concrete Baching Plants For Sale In South Africa

- China Stone Sand Washer

- Mill Rental In Tunisia

- Environmental Impact Of Mining Problems And Solutions In South Africa

- Crusher Plan For Sale Canada

- Process Iron Ore Crusher

- Stone Crusher Partikel

- Silica Sand Price In Jamshedpur

- What Is A Coal Washery With Images Ppt 039 S

- Mining Of Metal Ores In France Isic Free

- Used Mining Plant And Equipment