Limestone Crusher Cement Manufacture

Cement Manufacturing Process | Phases | Flow Chart ...

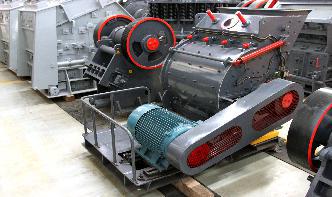

Aug 30, 2012 · Crusher reduces the size of large rocks to the size of gravels. Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding.

process of impact crusher indonesia

mobile crusher crusher machine sand making machine. Grinding mill *. Production capacity: 200300t/h 100200t/h 50100t/h 3050t/h <30t/h *. Broken materials: granite basalt limestone Pebble sand stone. marble concrete Construction waste other. expected size: 05мм 5100мм 100300мм 300500мм.

Cement Plant | Cement Manufacturing Plant | EPC Project

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them.; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.; Clinker production: In the cyclone preheater system, the raw material powder exchange .

China Limestone Crusher, Limestone Crusher Manufacturers ...

China Limestone Crusher manufacturers Select 2021 high quality Limestone Crusher products in best price from certified Chinese Crushing Machine, Crusher Machinery suppliers, wholesalers and factory on

Quarrying Of Limestone For Cement Manufacturing

cement manufacturing process Limestone Crusher,Limestone ... The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement.

Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Limestone For Cement Manufacturing | Crusher Mills, Cone ...

SECTION 2: THE CEMENT MANUFACTURING PROCESS – Welcome to Marsh. approximately tons of limestone to produce 1 ton of cement. The raw materials are .. The cement manufacturing process has several inputs and outputs.

Manufacture of Portland Cement Materials and Process

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone. When mixed with water becomes a hard and strong building material.

Limestone Stone Crushing Plant – limestone crusher plants

Mar 17, 2016 · Limestone Stone Crushing Plant Limestone is mainly quarried for the construction of buildings, roadbeds and landscape construction. Limestone is widely used in cement production for the. Limestone Crusher|Limestone Crushing Plant|Limestone crusher SBM is a Professional Limestone Crusher manufacturer,Our products has been exported 167 countries and are widely used in global .

Limestone Crushing Solution

Limestone generally adopts dry crushing process. For metallurgical and construction use limestone, only the ore needs to be crushed and screened. If you want to further produce fine powder limestone products, use a jaw crusher, impact crusher or cone crusher to crush the raw ore and then use raymond mill to grind the product.

Cement Manufacturing Process: How the Cement is Made?

All the cement plants set up after 1980 use the dry process for the manufacture of cement. In this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks. The argillaceous material such as clay is thoroughly mixed .

Limestone Crusher In Cement Plant

cement plant crusher for limestone XSM is a leading global manufacturer of crushing and milling equipment (cement plant crusher for limestone) ... Read more limestone crusher in cement plant

Portland Cement Plant for Sale | New Dry Process of ...

In the Portland cement manufacturing process, most raw materials need to be crushed first, such as limestone, clay, iron ore, and coal. Limestone is the main material for Portland cement production, and the particles of limestone generally have a large size and strong hardness when they are mined. Therefore, it is quite necessary to crush them (with

Manufacturing of Portland Cement – Process and Materials ...

Apr 13, 2020 · The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical .

The Cement Manufacturing Process

The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines. Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles. Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers. As mentioned earlier coal is used as a fuel to heat the raw ...

aggregate Limestone crushed, aggregate Basalt crushed ...

Home » Forum » Cement Trading Forum » aggregate Limestone crushed, aggregate Basalt crushed stone, Cement,Clinker 32 posts Time Posted 23/10/2019 22:56:40

Manufacturing process | Lafarge

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers which transport the materials and unload into hoppers ...

Cement Manufacturing Technologies

Cement manufacture, like many other manufacturing processes, begins at the mine, where the raw materials like limestone, silica, aluminates and others are obtained. Customer Cases Capacity of PreGrinder in Cement Industry 2011 China Forum of Cement... The Importance of Crusher in Cement Industry How to Choose Crushers for Cement Plant

Limestone For Cement Manufacturing | Crusher Mills, Cone ...

Roller Mill Mobile Jaw Crusher Suppliers In Malaysia; Crusher Ube Mill Three Roll Details; Trowel For Gold Mining; Please feel free to give your inquiry in the form below. We will reply you with details ASAP. Email: * Tel: Machine: * Message: ← Previous Next → Limestone For Cement Manufacturing. CementPedia – Manufacturing Process of Cement. The process of cement .

Cement

Jan 04, 2016 · Bouldersize limestone rocks are transported from the quarry to the cement plant and fed into a crusher which crushes the boulders into pieces Manufacturing of Cement (contd) 36. 43 • The limestone pieces then go through a blender where they are added to .

Cement Manufacturing Process: What is Cement made of.

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

Latest Posts

- كسارة مطحنة النبات للتعدين على نطاق صغير

- طاحونة المطرقة للبيع كريغسليست

- كسارة الصخور الأسفلت المستخدمة

- مطحنة دقيقة جدا الجزائر

- تستخدم خام الحديد الفك محطم مزود في اليمن

- الغرانيت البريد آلة طحن

- هارد روك مصر

- آلة تستخدم حجر طاحونة السودان

- الكرة مطحنة في المملكة العربية السعودية

- معدات تعدين الخبث للبيع في شيلي

- بيع معدات تكوير الحديد

- صنع سلسلة كسارة السكر في مصر

- مصنع المحجر محطم الصربية

- مطاحن الحجر الجيري في الجزائر

- كيف حجر عمل كسارة

- Second Hand Crushers In Italy

- Mining Washing Machines

- Marble Crusher For Sale In Nigeria And Botswana

- Iron Ore Crusher Distributor In Indonesia

- Mobile Crusher In Bangladesh

- Mercury Recycling From Gold

- American Owned Company That Mine Gold In Afghanistan

- Documentation Impact Mill For Powder Mtm16

- Mesin Berat Jaw Crusher Mini

- Process And Flow Diagram For Cotton Ball Manufacturing

- Stone Crusher Sizes Malaysia

- Grinding Machines Builder

- How Is Pyrite Mined Or Processed

- Diseo Y Construccion De Maquinas De Cereales Inflados

- Pelletizer Limestone Crusher Price