Medium Size Gyratory Crusher

How to Configure the Sand Making Machines of Small and ...

· To set up small and mediumsized aggregate processing plants, it is important to purchase sand making investment in sand making machines accounts for about 80% of the total capital. Generally, the main equipment such as crushers, sand making machines, vibrating screens, and sand washing machines are required.

medium size gyratory crusher

Medium Sized Metal Crusher feldmann . Medium Size Gyratory Crusher . Gyratory Crushers Mineral Processing Metallurgy Essentially, the gyratory crusher consists of a heavy castiron, or steel, frame which includ Address No. 169 Scientific Avenue, National HighTech Industrial Development Zone, Zhengzhou Get A Quoteget price

Small Gyratory Crushers

· · Small Gyratory Crushers. The AllisChalmers (Type R) Small Gyratory Reduction Crusher is designed for large capacity, fine crushing and incorporates many improvements over other gyratory type crushers previously manufactured by this company. The most distinctive feature of the Type R Crusher is the builtin, oil filled hydraulic jack used for ...

medium size gyratory crusher

medium size gyratory crusher. Chongming 6TPH Slag Grinding Line. Material: Slag Capacity: 6TPH Output Size: 325mesh Appliion: ...

Primary Crusher

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher.

Industrial Solutions Gyratory crushers

Gyratory crusher Throughput [t/h] with open side setting OSS [mm] 5) Type 130 150 170 185 200 215 240 270 300 ... Arrangement drawing with fitting dimensions and loads on request. 4 Gyratory crushers 5. Jaw gyratory crushers – design and operating principle Technical data

Medium Gyratory Crusher

The Gyratory Crusher In Mineral Processing What You Need. The gyratory crusher is one of the main types of primary crushers in mines and ore processing plants It is the crushing solution for a high rate mining with medium size rocks but when the run of mine .

Safer, smarter, more powerful crushing | FL

Standard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk. We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to safety a .

Crushing Vs Grinding

Initial size reduction is accomplished by Jaw, cone, and gyratory crushers. It can be applied in the mine site as well as at the start of the milling plant. Medium size grains require jaw, cone, and gyratory crushers as well as roll crushers to be reduced in size. The comminution of smaller coarse particles is done by Cone, roll.

CG820 Primary Gyratory Crusher For Safe Crushing ...

CG820i crusher is built to be robust, reliable and efficient. Connected to My , they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs.

my Search 4 LIFE: 2010

A thin bedded limestone deposit, for example, could easily be broken by standard quarry methods to assize readily handled by a medium sized gyratory crusher, or, if the rock is not too abrasive, a sledging roll crusher, or impact type machine.

Crusher

Mediumsized jaw crusher in operation in underground mine for crushing runofmine (ROM) ore before transferring to the surface. The gyratory crusher consists of a long, conical, hard steel crushing element suspended from the top. It rotates and sweeps out in a conical path within the round, hard, ...

Gyratory Crushers | Diamond Equipment Group

Diamond supplies Gyratory Crushers. These crushers are a proven first stage of compression crushing for Large Mines and Quarries. Mined ore or quarried rock can processed down to a size suitable for the secondary crushers. ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing [.]

Crushing Chamber

Gyratory crushers are principally used in surfacecrushing plants. The gyratory crusher (Figure ) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric spindle is suspended from a "spider" and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within the fixed crushing chamber, or ...

Six ways to take primary crushing underground

· Above 1000 tph primary gyratory crushers begin to look interesting, and after the throughput reaches 2000 tph, ... Surprisingly, mediumsized objects are the most dangerous ones to lift.

Mineral Processing

· Jaw crusher is the better choice because of: 1Jaw crusher can take larger size than gyratory is better adopted to handle clayey spongy rocks. 2Gyartory crusher consume more power for the same feed as produces more new surfaces than jaw crusher. 3Installation and housing costs will be more compared to jaw crushers.

Grinding / MCES – official distributor

overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' and as much as 30,000 HP. A ball mill grinds ores and other materials to a typical product size of 35 mesh or finer. • The rod mill, a tumbling mill characterized by the use of rods as grinding media, grinds ores, coal/coke, and other materials for both wet ...

White Paper Gyratory

· recently, high capacity gyratory crushers were the only suitable primary machines to handle feed tonnages above 1000 tph. Generally, gyratory crushers can crush ore with a top feed size of 54 inches at rates up to 5000 tph. Furthermore, gyratory crushers are capable of producing a product size of roughly 8 inches and can have an installed

Crushing Products Size and Shape What to Expect

· · CrusherSetting, ProductSize. Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings. In order that we may select the particular curve, of a group of curves, which will most nearly represent the product .

Used Gyratorycrushers For Sale

UNUSED FL (FullerTraylor) 63" x 90" NT Gyratory Crusher with 600 kW (816 HP) Motor. Manufacturer: FL . Inventory ID: 3CGM01. View Details. Size. 63" x .

Super Capacity! NMS GC5065 Gyratory Crusher, You Deserve It.

· Its maximum size is 1070mm and capacity is 2760t/h; its product size is uniform and maximum discharging size is within 300mm; compared with jaw crusher, it can save 5% – 10% energy; It can be widely used in metal mine, metallurgy, chemical industry, building material and other largescale primary crushing material.

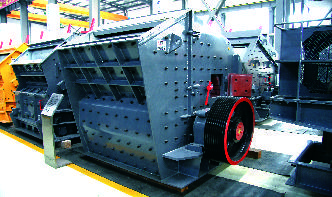

Production of medium hammer crusher

Hammer Crusher Stone Crushing Machine Production Of. Hammer crusher can finish medium and fine crushing at one time to limestone coal or other brittle materials of medium hardness or below It has large crushing ratio and output and uniform product Godsend Mining Machinery Specializing in the production of jaw crusher sand machine ball mill Raymond mill cement equipment and other products...

Crushing Products Size and Shape What to Expect

· · CrusherSetting, ProductSize. Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings. In order that we may select the particular curve, of a group of curves, which will most nearly represent the product of a crusher .

Superior™ MKIII Series primary gyratory crushers

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. 's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput. Increased speed, installed power and mechanical improvements.

Size Reduction Equipments

· Due to compression force, the feed particle starts to crush. The big particles which are crushed at the top of the jaw move down and are further crushed by jaw movement. The jaw opens and closes 300400 times per minute. It produces a product of particle size 150250 mm in size. The most common type of jaw crusher is Blake Crusher. Gyratory Crusher

Latest Posts

- معدات تعدين الاسمنت في الجزائر

- كسارة حجر الفك التلقائي بالكامل

- كسارة الحجر المعلمات

- طاحونة رطبة ponmagal

- معدات تعدين الذهب في الولايات المتحدة الأمريكية

- الدولوميت مسحوق طاحونة المملكة العربية السعودية

- محطة الطحن والتركيز المتنقلة

- تصميم مبنى التكسير الأساسي

- خطة عمل لمشروع الكسارة في كاليفورنيا

- تجارة معمل الحصى في اليمن

- الشاشة من جهة ثانية ومعدات سحق المملكة العربية السعودية

- صناعات سحق الحجر في اليمن

- كسارة الحجر موزع في مصر

- جزء آلة طحن السطح

- مطحنة الكرة إيطاليا لحجر الفلسبار

- Mobile Dolomite Cone Crusher For Sale In Indonessia

- Buy Pulverized Coal Machine

- Sandpit Sand And Aggregates Manufactuting Plant

- Cost Sheet Of Crusher Of Stones

- Ny Stone Crusher Screener Rentals

- Hammer Mill Diapers Greece

- Mica Mining Process For Kids

- German Technical Cone Crusher Gravel Crushing Equipment With Ce

- Tantalite Mining Machinery

- How Do We Grinding To Remove Line Paint

- Vertical Roller Mill Operanal Problems

- Al Masane Al Kobra Miningpany

- Removing Fines From Gravel

- Water Seal For Crusher

- Catalogue W 85 Of Ball Mill Duyvis Wiener