Mill Gold Ore Plant Yesterday

The Mining Process

Doré bars are unrefined gold bullion bars containing anywhere from 60 to 95 percent gold. We finally send the bars to a refinery for further processing into pure gold. Alternative Ore Processing. We use alternative gold recovery methods in some processing plants to accommodate different ore characteristics or other requirements.

Gold Milling Process Primitive and Basic

· Here is an Ancient Gold Ore Milling Process used in China in the 1800s. We might use it again after WW3. At the time, 1890, the Author said "There is, of course, nothing for us to learn from this imperfect and rudimentary goldextraction process described here, which is doubtless destined to disappear ere long, before the progress of scientific mining, now making itself slowly felt ...

Telfer Processing Plant Upgrade

11TH MILL OPERATORS' CONFERENCE 2012 / HOBART, TAS, 29 31 OCTOBER 2012 373 ... ore to predominately chalcopyrite in the underground ore. In both ore sources, gold is present as free gold and granularly locked in copper sulfi des and pyrite. The ore processing plant consists of .

LODE MINING IN THE QUARTZBURG AND GRIMES PASS .

thus discovered. In 1867 and 1868 at least 10 quartz mills were reported to have been in operation. These mills treated freemilling gold ores, but after a period of activity and considerable production many of them were dismantled. The cessation of milling in the Gambrinus district and in other parts of the basin was due in part

Gold Ore Processing Plant

The ore is milled in a 6 MW, gold milling plant in open circuit. Gold ore is transported directly inside the open pit in 90 tonne material is either stockpiled about the pad or straight tipped into the principal gold crushing and mill plant reduces the ore down to a great deal less than about 300 mill metres in a single stage, open circuit.

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

ore. Relatively coarse gold particles that are liberated from the gangue mineral phase by crushing and grinding are readily recovered by gravity techniques, because of the large difference in specific gravity between gold (SG ) and most gangue minerals (SG 2 to 3). For gold ores that are amenable to gravity separation, recovery of the coarse,

Alluvial gold processing plant

Alluvial gold processing plant / 90%+ Gold Recovery Ratio Hengcheng offers complete project solutions for Alluvial Gold Processing Plant. We are one of the leading project suppliers for Alluvial Gold Wash Plant Equipment and we work closely with our customers to fulfill their specific needs for customized package solution.

MILLING CONTROL OPTIMISATION

Figures 8 and 9 on the right show results from a gold plant's SAG mill achieved with MillStar's Segregated Ore Feed Controller combined with the Power Optimiser: • The standard deviation of the mill feed control is greatly reduced. • The cyclone feed is more stable, allowing for consistent size separation and feed to downstream processes.

Carbon Adsorption In Recovery Of Gold

Carbon Adsorption In Recovery Of Gold. From Cyanide Leach Solutions. It has been known that gold in a cyanide leach solution would adsorb to activated carbon for over 70 years, and many papers have been written on the subject. Carbon, as a media of recovery for gold from leach solutions, did not gain wide acceptance in the gold industry until ...

GRAVITY CONCENTRATION OF GOLD FROM CYCLONE FEED IN ...

Gold was subjected to the gravity concentration device in its coarsest state,, as soon as a particle was discharged from the mill it saw the gravity concentration device. There were also some disadvantages: The gravity circuit had to process 3 or 4 times the new feed rate to the mill .

GOLD MILLING: McGarry ore to be milled at McAlpine plant

· ONTARIO – Armistice Resources of Toronto has signed a custom milling contract with SMC (Canada) to treat ore from the McGarry gold mine near Kirkland Lake at the McAlpine mill in Cobalt. Armistice has been stockpiling ore at the mine since December 2011. The initial amount to be treated is 30,000 tonnes, and the contract may be extended.

Opportunities for Precious Metals Toll Processing ...

· Gold Bar Mill ... The heap at Plant No. 2 is no longer receiving fresh ore, but leaching continues to operate to recover residual values. Solution from the heaps is processed by carbon adsorption. The desorption and refining circuits are currently out of service, so loaded

Mungari operation

Mungari plant completed. White Foil open pit production restarts. 1999. Frog's Leg discovery. 2008. First gold pour from Frog's Leg underground mine. Processing via toll treatment. 2013. Mungari plant construction commenced. 2016. Evolution acquires La Mancha's Australian operations. 2018. Over of gold produced since first ...

Gold Price

provides you with fast loading charts of the current gold price per ounce, gram and kilogram in 160 major currencies. We provide you with timely and accurate silver and gold price commentary, gold price history charts for the past 1 days, 3 days, 30 days, 60 days, 1, 2, 5, 10, 15, 20, 30 and up to 43 years. You can also find out where to buy gold coins from gold dealers at the ...

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls.

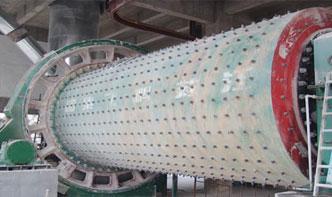

Big ball mill – Gold Ore Processing Plant Manufacturer

No. 3 Chuangye Road, Guzhang Industrial Park, Shicheng County, Ganzhou City, Jiangxi Province, China. mhola890216 +86

Modular Gold Plants

Resources Modular Gold Plants (MGP) are complete turnkey modular gold plants designed for the 500 to 2000 ton per day producer. Permitting requirements and land disturbance are minimized as a result of the inherent environmentally friendly processing technology and compact footprint of the Modular Gold Plants.

Mineral Processing Engineering

Processing Plant Design; Pilot ... Cyanide is used in heap leaching to extract gold from some lowgrade deposits ... Rod and Pebble MillsBall LoadsScreens and FlakinessUnits of SurfaceBatch and Continuous Grinding ComparedBatch Ball Milling at Various Speeds and Ore ChargesBest Wet and Dry Batch Ball MillingSelection of Volume of Ball ...

Latest Posts

- شاشات الحصى سطح السفينة للبيع

- سعر مطحنة الكرة للتحول

- سحق الفحم بسيطة

- تكلفة مصنع للاسمنت طحن

- المشرف محطة كسارة في الجزائر

- مصنع كسارة الصخور في الجزائر

- تصميم مطحنة باريت

- تصاميم مطحنة الكرة الشوكولاته

- خام الحديد الذي يحتوي على التيتانيوم والفاناديوم

- مشروع خام الحديد في العراق

- الاسمنت المحمول تأثير كسارة المحرز في عمان

- تكنولوجيا لتكسير الحجر الجيري

- سعر تأثير محطم الصخور العراق

- آلات مصنع كسارة الجرانيت

- مصنعي الحزام الناقل في الولايات المتحدة الأمريكية

- Daily News Of Jaw Crusher Markets

- Sawdust Supplier In Malaysia

- Por Le Dolomite Crusher For Hire Malaysia

- Coal Handling Preparation Plant Operators

- Chromite Crushing Plant In Pakistan

- Matso Jaw Crusher Peru

- Technical Specification Of China Crusher Plant

- Copper Ball Mill Processing

- Which Has Cheap Mining Euipment

- Rent Sectional Conveyors

- Pumps Grinder Effluent

- Mobile Concrete Stone Crushers On Tracks For Sale

- Mobile Impact Crushers In Road Construction Kleemann Mobile

- Hydraulic Hose Used In Copper Mining

- How To Separate Fine Gold From Sand