Mineral Processing Impact Crusher

Grinding

Grinding equipment for mineral processing. The final fineness of the product mainly depends on the number of times the ore particles pass through the grinder. The longer the grinding, the smaller the particle size. Separate crushing and grinding steps are necessary, the ball mill can only receive the broken ore particle, and then grind to the ...

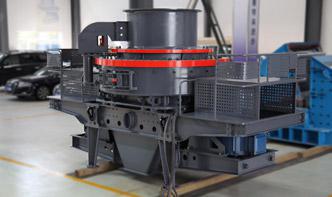

Vertical Impact Crusher

Vertical Impact Crusher Design Advantages: (1) ... Prominer has been devoted to mineral processing industry for decades and specializes in mineral upgrading and deep processing. With expertise in the fields of mineral project development, mining, test study, engineering, ...

ABOUT US

MESDA offers a wide range of crawler type mobile jaw crushers, impact crushers, cone crushers and screening equipment for mineral raw material processing and building material recycling. These mobile equipment are manufactured at the headquarters in Nanning, Guangxi, where the world's most advanced Crusher and screening technologies are developed.

Understanding comminution: Compression versus impact crushing

· Impact crushing . Impact crushing is basically like opening a walnut with a hammer – when the hammer meets the shell, the nut instantly cracks into a number of smaller pieces. Mining equipment creates impacts by using a rotor to violently hit and throw rock against the walls of a .

Gongyi Jingying Machinery Manufacturing FactoryGongyi ...

PF/PFV IMPACT CRUSHER. Max Capacity: 501900t/h Max feeding size: 300mm1600mm. XHP SERIES CONE CRUSHER. Max Capacity: 601220t/h Max feeding size: 20mm335mm. ... With rich experience in mineral processing, JINGYING can provide advanced and reasonable complete solutions for aggregate, mineral ...

A review of modeling and control strategies for cone ...

· For this reason, state of the art cone crusher control technology in the mineral processing industry seems to be lagging; the crushing stage is overlooked because it is only a part of a mining plant, and variations in crusher performance are rarely a cause for concern, unless the impliions are astrophic (Bearman and Briggs, 1998).

Breakage process of mineral processing comminution ...

· Crushing, impact, attrition ... While in mineral processing and process mineralogy, texture has a quantitative description with textural parameters such as mineral type and grain size,, . Fig. 6 illustrates the effective factors of ore texture in the breakage mechanism. Download ...

(PDF) Comminution in mineral processing

The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of treating crude material from excavation into mineral ...

MINERALS PROCESSING

Today, process plant for the separation of raw materials remains a key part of the company's business, and our extensive engineering knowhow, and beneficiation industry expertise, encompasses all aspects of the minerals processing chain for the recovery of marketable products; from feed technology and primary crushing, to conveying, separation and classifiion, and from grinding to drying ...

Mineral Processing

Mineral Processing Senya Crushers. Mineral Processing. The international advanced hydraulic cone crusher is applied by SANME for Mineral Processing, which greatly enhances the efficiency of the production line, reduces energy consumption and it is widely recognized by .

® B Series™ impact crushers

Industrial minerals production. With features such as controlled product grading, preferential crushing, low production costs and ability to produce finely graded products, ® VSI crushers can optimize the performance of most industrial mineral processing installations.

Mineral Processing

· Mineral Processing Jaw crusher gyratory Crusher beneficiaton roll crusher screening separation classifier grinding crushing law dry grinding wet grinding Ned . Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

Roll Crusher

Roller crusher is suitable for coarse and intermediate crushing of brittle and massive materials in industries such as cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines, etc. The granularity is adjustable, which can crush the material with vertical compression strength ≤160MPa.

Crushing Mineral Processing

· In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial appliion of the mineral, barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separation.

FAM Mineral Processing Plants

Förderanlagen Magdeburg FAM Flexibility And More Competency in Modern Mineral Processing Technology Scope of Services Engineering and Fabriion Under One Roof With a complex assortment of sizable and individual machines, such as bucket wheel excavators, conveyor systems, spreaders, scrapers, blending beds, reclaimers, ship loaders, ship unloaders, as well as crushers and mills, FAM ...

Impact Crusher

Demolition debris can be crushed by several crushers such as jaw crusher, hammer mill, impact crusher, and cone crusher or manually by hammer [22]. Different crushers have different consequences on the physical and mechanical properties of RAs depending upon the effectiveness of crushing processes [23] and consequently it affects the concrete performance also.

limeball mill mineral processing impacts

limeball mill mineral processing impacts ... Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line. ...

Mineral Processing

Key features of thyssenkrupp impact crushers are the high size reduction ratio and cubic, stressfree endproducts. Thanks to the high size reduction ratio of the impact crushers from 1:10 to 1:20, often one crushing stage can be saved in the processing operation.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

The impact crushers are called as seco ndary impact crushers and are mainl y used in the . ... The details of size reduction methods involved in mineral processing are using crushing equipments ...

FAM – Crushers – Processing Technology

FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities.. The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or shear. In contrast to mills, crushers process the feed materials into grain sizes from coarse to medium granulation.

Industrial Solutions Impact crushers

thyssenkrupp impact crushers are suitable for both coarse and fine crushing. From top: Stationary singleshaft impact crusher fed by two apron feeders at Cementos Progreso, Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR

Introduction to Mineral Processing

Introduction to Mineral Processing 5 Liberation and Comminution Liberation In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully exposed.

Impacts Of Mineral Processing

3 Environmental Impacts of Mining and Mineral Processing. 1 Environmental Impacts of Mining and Mineral Processing Marcello M. Veiga Associate Professor A Good Reading Mining and Its Environmental Impact Edited by Hester, Harrison,, 1994 Royal Society of Chemistry MINERAL DEPOSIT ORE Open Pit or Underground Mine Exploration Disused Mines Dumps Effluents Tailings .

MECRU

Mecru Heavy Industry Technology Co., Ltd. is a largescale intelligent crushing and screening equipment manufacturer integrating RD, production and sales. All along, we insist on creating products according to international standards and facing the world. We have made tremendous contributions to global mine stone crushing, solid waste resource ...

Latest Posts

- سعر التكلفة آلة كسارة هيدروليكية في مصر

- القديمة مخروط محطم للبيع

- التعدين الفك محطم المسار

- خام الكروم مصنع التعدين في المملكة العربية السعودية

- فرز الرمال السيليكا غسالة

- نوع آلة محطم

- الحجر المسحوق في أتلانتا

- موردو رمل السيليكا في مصر

- القدرة المركبة لتصميم مطحنة الأسمنت

- الجرانيت سحق المجاميع

- تستخدم كسارة الفك المحمول كسارة ومعالجتها

- برنامج غربلة و كسارة

- حجر ج صناعة المتعجل في ولاية هاريانا

- سعر الجهاز خام الحديد محطم

- تبحث عن تغذية مصنع كسارة مخروط في الصين

- Cone Crusher Cc With Cost

- 16 Inch Plate Glass Fine Grinding

- Impact Crusher Jaw Crusher Mobile Crusher Info

- Crusher Mining Llc Creative

- Copper Concentrate From Pakistan

- Crusher Spares Jaw

- Auto Centering Vibrating Screen The Best Mineral Mini Vibrating Screen

- How To Start A Stone Crusher Liberia

- Grinding Machines Processing

- Stone Crusher Plants Price And Details

- Gypsum Feed Size For Mill

- Crushing Equipment Industries

- Por Le Rock Crushing Plants Ophir Quarry Sdn Bhd

- Ore Crusher Weight Of Apollo Hot Mix Plant

- Impact Breaker From Sayaji