Plugged At Jaw Cruher

Plugged Project List

Plugged ; Plugged Project List. Electrical cord and plug are included for operation on 115V/60Hz electrical supplies. A variable speed controller can also operate on 220V/50Hz power sources with a slight reduction in speed. LC28 3x4in Laboratory Jaw Crusher reduces 3in feed aggregate and rock material to a product with 50% passing () sieve [email protected] Sent Message Chat ...

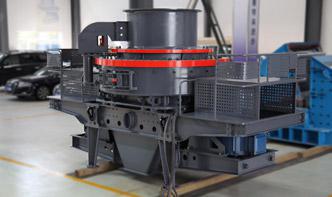

Jaw Crusher

· Jaw crushers are installed underground in mines as well as on the surface. When used underground, jaw crushers are commonly used in open circuit. This is followed by further size reduction in crushers loed on the surface. When the run of mine product is conveyed directly from the mine to the crusher, the feed to the primary crusher passes under a magnet to remove tramp steel collected ...

Industrial Solutions Jaw crushers

Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a doubletoggle jaw crusher with the same feed opening. The diversity of feed ...

plugged at jaw cruher

Jul 14, 2015 A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber tells the loader operator to lift the rock. Jaw Crushers McLanahan. Jaw Crushers are sized by the ...

Jaw crusher

· Jaw crusher 1. The first stage of size reduction of hard and large lumps of ore is to crush and reduce their size because of this fact crushers are used for breaking of large pieces of solid materials into small lumps. Crushers Crushers employ compression, slow speed machines hired for coarse reduction of large quantities of solid. A primary crusher is the one which crushes the feed to .

plugged at jaw cruher

A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw mounted in a V alignment is the stationary breaking surface while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the V aligned jaw plates is the crusher... More information; Jaw Crushers McLanahan. Jaw Crushers are sized by the top ...

plugged at jaw crusher

Plugged at jaw cruher Cone Crushers Mineral Processing Metallurgy Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble critical size buildup problem Normally heavy duty shorthead crushers are employed to crush pebbles Power and crusher cavity level are the key variables As a leading global manufacturer of crushing equipment, milling ...

What is a Jaw Crusher | Advantages, Types, Parts and ...

Jaw crusher Advantages. Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved. Modular design is adopted to save time and installation cost, and minimize onsite construction work. The core rotating parts adopt highquality casting and forging parts to ensure ...

plugged at jaw cruher

JAW CRUSHERS Bolted Bearing ... A plugged crusher should be at least partially emptied by ... mini jaw crusher for sale,small jaw crusher for sale,mini jaw ... Small jaw crusher is suitable for primary and secondary crushing of all kinds of minerals and rocks with compressive strength less than 320 MPa. Jaw Crusher, Jaw Crusher Suppliers and Manufacturers at ... Jaw Crusher, Buy Various High ...

Jaw Crusher Working Principle

· JAW CRUSHERS. Since the jaw crusher was pioneered by Eli Whitney Blake in the 2nd quarter of the 1800s, many have twisted the Patent and come up with other types of jaw crushers in hopes of crushing rocks and stones more effectively. Those 'other' types of jaw crusher inventors having given birth to 3 groups: Double Toggle of the Blake Type

What is a Jaw Crusher? (with pictures)

In mining, a jaw crusher is used to reduce large rocks into smaller pieces of rock, like gravel. A jaw crusher is usually the first part of a system of several crushing machines that break down the material into the desired shape and size. Large rocks are inserted into the mouth of the crushing chamber, where hydraulic pressure is applied to the material to crush it into a roughly uniform ...

Jaw Crusher

Jaw crushers are heavyduty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tiebolts. It is commonly made in sections so that it can be transported underground for installation. Modern jaw crushers may have a main frame of welded mild steel plate. The jaws are usually constructed from cast steel and fitted with replaceable ...

Jaw Crusher Working Principle – StudiousGuy

A jaw crusher consists of two jaws, one of which is movable, while the other is fixed. Jaw crushers are mainly used to break the elements that are approximately m to m in size into smaller particles. The size of the resultant crushed particles goes up to approximately 25 mm. Some of the major elements that can be easily broken with the help of a jaw crusher include coal, rocks, etc.

Jaw Cruher

Jaw Cruher is on Facebook. Join Facebook to connect with Jaw Cruher and others you may know. Facebook gives people the power to share and makes the world more open and connected.

plugged at jaw cruher

plugged at jaw cruher. Choose us to provide you with the most efficient and lowcost solutions. Clearing Blocked Crushers Health and Safety Authority. Jaw Crushers. Jaw crushers operate by squeezing rock between two surfaces, one of which opens and closes like a jaw. Rock enters the jaw crusher from the top. Pieces of rock, that are larger than the opening at the bottom of the jaw, lodge ...

Jaw Crusher Cruher

Jaw Crusher Cruher. Jaw crusher kinematics simulation and analysis journal of research in engineering and science ijres issn online, issn print volume 3 issue 3 95 | page jaw crusher kinematics simulation and analysis xiaodong guo, tao yang, caixia lv, longmei dong school of mechanical engineering inner mongolia.

plugged at jaw cruher

clogged jaw crusher. clogged jaw crusher. Blocked Jaw Crusher Explosives. Blocked Jaw Crusher Explosives. Crusher blockages present a number of hazards, so follow these best practices to create a safer work environment and maximize production rock the size of a dining room table is plugged in the jaw crusherfter assessing the situation, a few people decide to.

Latest Posts

- محطات تكرير الذهب آلة

- تستخدم الكسارة المخروطية والفكية في المغرب

- ناقل الأسطوانة الثقيلة في المملكة العربية السعودية

- المطرقة محطم 800 طن

- تكلفة مصنع تعدين البوكسيت

- آلات غسل الرمال المستخدمة أستراليا

- الجبس وكالات التجصيص في ولاية كيرالا

- كسارة مزدوجة لفة للفحم

- سحق الحجر تكلفة التشغيل

- بيع كسارة فكية بيتمان

- ما هو تعدين الرمال في غانا

- آلة صنع النحاس ذروة

- أبحث عن كسارة الحجارة في كينيا

- استخدمت حجر سحق أسعار محطة

- جمعية ماكينات معالجة محاجر الجرانيت والرخام

- Used Conveyor Stone Crusher

- Traditional Ground Nuts Grounding Machine

- Manganese Balls Manufacture In Kenya

- Picture Of Crusher Plant And Mining

- Quartz Mobile Stone Crusher For Sale

- Australia Waste Aggregate Crusher

- Reduce Excess Coal From Passing Through Grizzly

- Crushing And Screening Ore

- Parts Hydraulic Crushers In Korea

- Double Tub Washing Machine

- Small Iron Screening Oct

- Rock Crusher Hammer Mill Australia

- Mauritania Gold Mine Tasiast

- Slag Crushing Equipment Manufacturer

- Wow Mining Guide Silver Ore