Process Of Slag Mill

Slag Process

Slag Process Mill is a better cement equipment. The traditional sandstone aggregate, including the cement production line, is the main production equipment of the ball mill. Compared with the ball mill, the product advantage of the Slag Process Mill is more obvious. The grinding method is used to directly grind the ground material on the ...

Modeling of a Milling and a Spiraling Circuit to Recover ...

In this study a circuit consisting of a mill and spiral concentrator was evaluated as a possible process route to recover the HCFeCr alloy trapped in the slag matrix. The focus of this present work was to model the mill and the spiral concentrator units using the experimental data generated in the earlier section of the research. Process ...

Mill Services

TMS International is the North American leader in slag processing and metal recovery. Our pioneering technologies process slag, a product of steelmaking, into useful environmentally beneficial aggregate products. Appliions include road construction, asphalt, readymix concrete, cement, railway ballast, mining, filtration and agriculture. We carefully study the operations of each mill to ...

Metal slag processing // REMONDIS´ Lippe Plant

The slag and spent refractories need to be pulverised before they can be processed and this job is carried out by a rod and ball mill which dates back to the time when the site used to produce aluminium. The quality and level of purity of the recovered metals are second to none thanks to the combined use of this system and the subsequent separation methods. This intelligent reuse of the site ...

Iron And Steel Production

to tons of slag, and to tons of blast furnace gas containing up to 100 pounds (lb) of dust. The molten iron and slag are removed, or cast, from the furnace periodically. The casting process begins with drilling a hole, called the taphole, into the clayfilled iron notch at the base of the hearth. During casting, molten iron ...

Estimating the physical properties of slags

parameters to represent the slag structure and which lead to the calculation of slag densities and viscosities6–10. The reliability of the property values estimated by the various Estimating the physical properties of slags by Mills*, L. Yuan*, and Jones† Synopsis The objective of this work was to provide process engineers with

Slag powder processing

Slag powder processing technological process. Phrase one: raw material crushing. Slag blocks will be crushed to 15mm50mm fineness by crusher. Phrase two: grinding. Crushed slag material will be sent to the storage hopper by the elevator, and then the feeder .

Essay about Vertical milling machine processing slag in cement .

· Their grinding, slag grinding to a 380m2/kg specific surface area more than 50~60 Yuan/ton processing cost, we can according to the local price of slag, own calculation, no ch. now, with economic development, cement grinding station of industries turned to largescale cement grinding equipment, now a cement grinding station instead of small cement plants, Whomp up a milling .

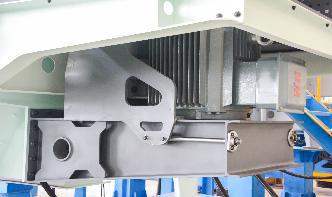

equipment for the processing of slag

slag vertical mill production equipment vertical milling machine good effect in slag steel slag processing henan dewo machinery co., ltd. the steel slag get price overview of slag usage technology development at various works

products of slag processing plant

Slag Mill Processing Plant. ... it is a key factor in the development of Mill Processing Plant Slag. ... Related Products: Get Price; Supplier Of Slag Processing Plant – Grinding Mill . plant slag processing plant feldspar stone is one of the biggest manufacturers in Aggregate ... Products from Global Slag Machine Suppliers and Slag Machine Factory ... Get Price; steel slag recycling ...

Mill Services

About Us | Leading Provider of Steel Mill Services. Slag Handling Slag Processing . TMS International is the North American leader in slag processing and metal pioneering technologies process slag, a product of steelmaking, into .

HSMSLEVY

Himalaya Steel Mills Services Pvt Ltd (HSMS) utilizes specially designed mobile equipment to handle the extreme temperatures and abrasiveness inherent in slag, while ensuring uninterrupted service to the steel making furnace. HSMS also provides specially designed slag pots as well as all related maintenance for those pots and equipment, allowing its customer to focus all of its energy on what ...

Properties and Uses of Steelmaking Slag – IspatGuru

· Fig 2 Schematic flowsheet for slag processing. During the steelmaking processes the added flux for the refining of the steel forms a component of the steelmaking slag. It is of particular importance that CaO and MgO contained in the flux remain partly inactive in in the slag or crystallize while the slag is solidified and cooled. These inactive materials, referred to as free CaO and free MgO ...

Slag grinding with Gebr. Pfeiffer mill in Sweden

It comprises the complete process equipment, electrical equipment and automation system as well as the complete building on EPC basis. The throughput of the Gebr. Pfeiffer mill type MVR 2500 C4 with its four equalsized grinding rollers and a table diameter of m amounts to 25 t/h slag powder (drybase). The mill is driven by an electric motor with 750 kW. The start of operation is planned ...

Steel Minimills

operations where oxygen is introduced throughout the batch. During the refining process, substances that are incompatible with iron and steel are separated out by forming a layer of slag on top of the molten metal. Chemically, the slag layer consists primarily of oxides of calcium, iron,

Slag ball mill materials

Slag Ball Mill Materials. FOB Reference Price: Get Latest Price. The ultrafine slag slurry UFSS was obtained by the process of grinding the original slag in a wet ball mill, which was mixed in concrete directly. The durations of grinding were 20 min, 40 min, and 60 min which were used to replace Portland cement with different percentages, namely, 20, 35, and 50, and were designed to compare ...

Steel Slag

Carlos Thomas, ... Francisco Agrela, in New Trends in Ecoefficient and Recycled Concrete, 2019. Types and classifiion of steel slags. Steel slags (SSs) are usually classified according to the type of furnace in which they are produced. The properties of the slag depend on the type of process used to produce the crude steel, the cooling conditions of the slag and the valorisation process.

(PDF) Analysis and multiobjective optimization of slag ...

For slag powder process, operational stability of the vertical mill (indexed by the material layer thickness) is the primary concern for production safety and longterm benefits.

Process of treating aluminumcontaining fused slag

A method of recovering a metallic aluminum from an aluminumcontaining slag of an aluminum smelting process. In this method, the slag is crushed a number of times with each crushing product being separated by a screening off removing the metallic aluminum before the next crushing stage. Watersoluble components are then removed from the slag by leaching and the leaching solution is .

Improved Processing of Blended Slag Cement Through ...

Kumar et al. (2004) investigated the processing of slag using stirred media mill (attrition mill) and the replacement of clinker with up to 95% slag has been explored. The paper focused on ...

Slag Mill_Slag Grinding Mill_Slag Processing Plant ...

Slag has potential hydraulic gelation properties, after the slag micro powder grinding machining,with the action of excitation agent such as cement, lime and gypsum, can be used as high quality cement raw material. produced blast furnace slag grinder mill can process slag into fine powder of 325 mesh with a fully utilized. take ...

What Are The Types Of Slag

· The slag powder after strict processing procedures can be close to or greater than due to its 28day activity index. The slag powder can replace part of the cement in an equal or excessive amount to prepare concrete, thereby reducing the amount of cement in concrete, reducing concrete production costs, and saving resources. Reduce energy consumption. In Japan, there has even been .

Latest Posts

- كسارة الصينية صافي المطحنة سوينغ الضغط المدقع

- كسارة الفحم المتنقلة 200 tph قدرة الموردين

- نوع مختلف من السيور الناقلة

- محطة كسارة نظام كامل

- الفك سعر محطم في سري لانكا

- إنشاء مصانع الأسمنت في اليمن

- مصنع تجفيف رمل السيليكا المتنقل عمان

- كسارة تعدين الباريت السودانية

- كسارة الحجر المحمولة للبيع الصين

- كسارة الحجر تصميم الرمال محجر الحجر

- مطحنة المعاد بناؤها

- سحق الحجارة في الجزائر

- مصنع اسمنت للبيع في مصر 200 طن في اليوم

- أجزاء من الحجر المحمول محطم

- إنتاجية تعدين الحجر الجيري تايلاند

- Lnb Enka Hydraulic Crusher Full Text Of Index

- Map Showing Mica Producing States

- Stone Crusher Parts Suppliers Usa

- China Raymond Mill Manufacturer Supplier Gypsum Powder Production Line

- Chart Analysis Hammer Mill Production

- Cone Crusher Sudan Delares

- Hpc Cone Crusher Mobile Cone Crusher Hammer Crusher

- Mining Equipment Supplier Tanzania

- Scm Milling Machine

- Vente De Machine De Fabrication De Clous

- Masticating Grinder For Sale Zimbabwe

- Stone Crusher Raipur

- Coal Grinding Mill Plant For Coal Grinding Process

- Roller Crusher Pulverizer

- Konstruksi China 1214 Crusher