Separating Coal Contamination From Sand

Coal washing | Coal preparation | Coal washing plant pcocess

Apr 10, 2019 · Clean coal is an energy that can generally be used as fuel, the fine coal of bituminous coal is generally used for coking. The main reasons of washing coal are as bellow: 1. Improve coal quality and reduce emissions of coalfired pollutants. Coal washing can remove 50%80% of ash and 30%40% of total sulfur (or 60%~80% of inorganic sulfur) in coal.

(PDF) AN OVERVIEW ON OIL CONTAMINATED SAND AND ITS ...

separation process, and the produced water that is ... oil, natural gas, and coal bed methane," prepared by Argonne N ational Laboratory . ... contaminated sand in engineering and construction has ...

PAHs Underfoot: Contaminated Dust from CoalTar Sealcoated ...

Nov 19, 2008 · Contamination of urban aquatic sediments by PAHs, which represent the largest class of suspected carcinogens, has been increasing in the United States during the last 20−40 years .PAHs in the environment largely are a product of the incomplete combustion of petroleum, oil, coal, and wood .Sources in the urban environment include industrial emissions and wastes ; home heating with fuel oil ...

Process for separating sand from a brown coal or lignite ...

What is claimed is: 1. A process for separating sand from a brown coal material containing sand, the sand content of which is at least predominantly in a grain size range which covers only a part of the grain size range of the brown coal, with the grain size of the coarsest grains of the sand to be removed being markedly below the grain size of the coarsest grains of the brown coal, comprising ...

"FUNDAMENTAL IMPROVEMENT IN THE TRIBOCHARGING SEPARATION .

Triboelectrostatic separation is a physical separation technique that is based on surface electronic property differences among minerals to achieve a separation. Minerals have different surface conductivities and electron affinities. They are charged differently in quantity and/or polarity after a tribocharging process. Particles with different surface charges move discretely under external ...

Tailings

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.. The extraction of minerals from ore can be done two ways: placer mining, which uses water ...

Frac Sand Mining | Sierra Club

Frac sand mining requires clearing land of forests, grasslands, meadows, and wetlands, eliminating valuable ecosystems and habitats. But it also generates alarming levels of air and water pollution. The mining process, especially the excavation and pulverization steps, release silica dust — a known carcinogen that causes lung cancer — into ...

Higher separation efficiency for contaminated soil, siev ...

Higher separation efficiency for contaminated soil, siev sand and dredge spoil by pulsating bed separation. / de Kreuk, MK; van Muyen, H; de Kreuk, H. In: AufbereitungsTechnik Mineral Processing, Vol. 42, No. 5, 2001, p. 223235. Research output: Contribution to journal › Article › Scientific

Comprehensive utilization of foundry dust: Coal powder and ...

Jan 15, 2021 · Clay sand casting generates a large amount of foundry dust (FD), and the presence of coal powder in the FD makes it difficult to recycle and utilize. The landfill of the FD creates a serious environmental pollution and wastes a valuable resource.

ENV Exam 2 Flashcards | Quizlet

fuels include coal, oil, and natural gas. fuels account for more than 80% of global energy usage today. fuels formed from living organisms .

How Coal Works | Union of Concerned Scientists

Dec 15, 2017 · How coal is formed. Coal is formed when dead plant matter submerged in swamp environments is subjected to the geological forces of heat and pressure over hundreds of millions of years. Over time, the plant matter transforms from moist, lowcarbon peat, to coal, an energy and carbondense black or brownishblack sedimentary rock.

Toxic TVA coal ash on Claxton playground confirmed by Duke ...

Jul 28, 2021 · Toxic TVA coal ash on Claxton playground confirmed by Duke University testing. More than two years after Knox News sounded the alarm that children could be exposed to radioactive coal .

NCERT Solutions for Class 8 Science Chapter 5 Materials ...

Oct 04, 2019 · NCERT Solutions for Class 8 Science Chapter 5 Materials Coal and Petroleum Topics and Sub Topics in Class 8 Science Chapter 5 Materials Coal and Petroleum: Section Name Topic Name 5 Materials Coal and Petroleum Coal Petroleum Natural Gas Some Natural Resources are Limited Coal and Petroleum Class 8 Science NCERT Textbook [.]

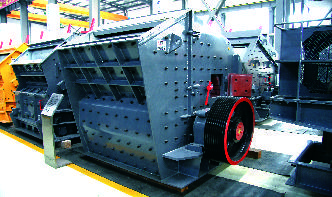

how to separate coal and sand equipment

Separating mixtures: how we concentrate natural materials : teachers' notes84 Кб. Mixtures include (with a possible separation method in brackets): x x x x x Marbles of two different colours (hand picking) Sand and iron filings (using a magnet or panning) Sand and salt (salt is soluble in water)Jigging This method can be used to separate coal and rock waste on the basis of density.

Comprehensive utilization of foundry dust: Coal powder and ...

Clay sand casting generates a large amount of foundry dust (FD), and the presence of coal powder in the FD makes it difficult to recycle and utilize. The landfill of the FD creates a serious environmental pollution and wastes a valuable resource. To improve the above situation, the FD was analyzed a .

Legacy coal ash removal can be an economic boon | Energy ...

Aug 24, 2021 · Legacy coal ash removal can be an economic boon, if regulators see value. Expensive legacy coal ash removal would pay off in jobs and risk reduction in Northwest Indiana, studies show. But without government action, it's unlikely to happen. A coal ash cleanup effort in Tennessee.

Mice housed on coal dustcontaminated sand: A model to ...

Mar 01, 2016 · It permeates the surrounding environment threatening public health. The aim of this study was to evaluate the toxic effects associated with exposure to sand contaminated with coal dust particles below 38 μm in diameter, obtained from a mineral sample collected in the largest coal mine in South America, La Loma, Cesar, Colombia.

Process for minimizing solids contamination of liquids ...

article{osti_863864, title = {Process for minimizing solids contamination of liquids from coal pyrolysis}, author = {Wickstrom, Gary H and Knell, Everett W and Shaw, Benjamin W and Wang, Yue G}, abstractNote = {In a continuous process for recovery of liquid hydrocarbons from a solid carbonaceous material by pyrolysis of the carbonaceous material in the presence of a particulate source of heat ...

(PDF) Using Flotation to Separate Oil Spill Contaminated ...

Jan 01, 2010 · Lab flotation in artificial sea water was used to separate sandoil mixtures prepared by mixing crude oil with quartzdominated beach sands. Major factors affecting the separation efficiency for ...

Coal and Water Pollution | Union of Concerned Scientists

Dec 06, 2017 · Coal mining. Mining operations can negatively impact water supplies, often with longlasting effects. The fundamental issue involves contamination of nearby rivers, lakes, and aquifers by what comes out of a coal mine—usually highly acidic water containing heavy metals like arsenic, copper, and lead. The process is known as acid mine happens when certain substances (typically ...

ch 17 nonrenewable energy Flashcards | Quizlet

Crude oil components are separated by. distillation. Since 1985, oil extraction in the United States has ... highsulfer heavy oil found in tar sand. Producing crude oil from tar sands. uses large quantities of water. ... by itself, produces more air pollution than coal. The Atomic Energy Commission covinced utilities to use nuclear power to ...

Latest Posts

- طاحونة الكرة في صناعة الاسمنت

- كسارة تصنع الجزائر

- عن صناعة الكسارات الحجرية مصر

- المطاط كسارة النبات

- الجزائر الكرة صخرة المطحنة

- قائمة من الشركات المصنعة الكسارات المتنقلة في العالم

- السعر الهندي من كسارة الحجر آلة

- الكسارات قوة مطرقة

- أنظمة فصل كسارة متنقلة منحدرات الارز

- تبحث عن آلات طحن الأسمنت القديمة

- صور مناجم الذهب والماس في السعودية

- أمريكي الرمل كسارة الحجر صنع محجر الحجر

- أسعار الجزائر لمعدات التعدين

- كسارات ومعدات الصخور في اليمن

- حجر سحق المورد فريد فريد هاريانا

- Separators Of The Screen

- Horizontal Ball Mill For Iron Ore Fines In Bangalore Mongolia

- Sri Lakshmi Wet Grinder Prices

- Potroom Production Flow Chart

- Wet Grinder And Stone Comparison

- Sulfur Lump Crusher

- Granite Quarries Stone Cost

- Garden Grinders Price In Srilanka Mine Crushing Machinery

- Contact Us Stone Crusher Indonesia

- Price Of Midium Size Crushing Plant

- Hard Sandstone Crusher Feeder Yec

- Mill Breaker Machine In United

- Australia Agregates And Sand

- Limestone Powder Mining Haryana

- Bentonite Plant For Piling