Structure Cone Crusher Principles

Cone crusher principle theory

Principles of the cone crusher Shanhu Group. Principles of pound cone crusher When the pound cone crusher works, the upper cavity of the moving cone is supported on the spherical bearing bush at the end of the fixed spindle, and the lower cavity sleeve is outside the eccentric shaft sleeve, and its motion is . Oline Chat

Jaw Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Appliions mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of ores.

Single Roll Crusher Working Principle | Prominer (Shanghai ...

Structure and Working Principle of Single Roll Crusher . Compared with jaw crusher or cone crusher its performance and compact structure all have advantages Next the experts of Machinery will give a detailed explanation of the structure and working principle of the single roll crusher . Get Price

What is the working principle of the Cone Crusher?

AIMIX cone crusher is a type of compression machine. The cone crusher has a smaller crushing chamber. Therefore, break the rocks by tightening them between the rotating spindles. In addition, these spindles are completely covered with a sturdy man...

Introduction to the structure, working principle and ...

Jul 14, 2021 · Jul 14, 2021 · The cone crusher gears are mainly composed of the main components such as frame, dynamic cone, eccentric shaft, transmission part and drive unit.. Working principle of cone crusher gears. When cone crusher gears are in operation, the eccentric sleeve is driven to rotate by the motor through the vbelt, large pulley, drive shaft, small bevel gear and large bevel gear.

Spring Cone Crusher For Gold,Iron, Copper ore | Prominer ...

Cone Crushers is widely used in mines, cement plants and sandstone industries for medium crushing of various mine rocks, such as iron ore, copper ore, nonferrous metal ore, granite, sandstone, etc. Working principle is as follows: The cone body swings under the force of the eccentric shaft sleeve, so that the concave is sometimes close to and sometimes away from the mantle, so that the ...

Mining Equipment, Breaking, Drilling Crushing Products ...

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebblecrushing appliions. Stationary jaw crushers jaw crushers are of the singletoggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton.

Working Principles Of Cone Crushers

Cone Crusher Working Principle. The basic principle of a cone crusher is depicted in Figure 9 and described here. A cone crusher consists of a circular outer concave, wherein a mantle, shaped like a ...

Feed Arrangement Cone Crusherfrom Kenya, Cone Crusher

Structure Cone Crusher Principles. Cone crushers are particularly suitable for crushing the cone crusher reduces the feed material by of the crushing tools and their structural arrangement get price cone crusher classifiion and characteristics with cone crushers on the market increasing demand cone crusher continuously updated 4 internal ...

Working Principle Of Cone Crusher | Crusher Mills, Cone ...

Here you can know more about Cone Crusher Structure and Cone Crusher Working Principle. working principles of cone crushers – CGM mining appliion who can tell me the working principle of spring cone .

Crusher Mining Stone Machine

Based on some design principles of traditional multicylinder hydraulic cone crushers like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, Multicylinder Hydraulic Cone Crusher makes a breakthrough on its structure. After optimization, the structure improves the performance and crushing capability a lot.

Cone crusher principle and equipment structure

Sep 24, 2019 · Sep 24, 2019 · Cone crusher principle and equipment structure. During the working process of the stone cone crusher, the motor drives the eccentric sleeve to rotate by the transmission device, and the moving cone rotates under the eccentric bushing. The section of the moving cone close to the static cone becomes the crushing cavity, and the material is ...

HPT Multicylinder Hydraulic Cone CrusherSBM Industrial ...

Based on some design principles of traditional multicylinder hydraulic cone crushers like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, HPT Multicylinder Hydraulic Cone Crusher makes a breakthrough on its structure. After optimization, the structure improves the performance and crushing capability a lot.

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Working Principle Of Hydraulic Conveyor

How hydraulic cone crusher works, Working principle Hydraulic cone... Hydraulic cone crusher works. Technical features of Hydraulic cone crusher. 1. HPC features simple structure, easy maintenance, convenient adjustment of the size of final products, especially the quick replacement of plate reduce the time to s the machine. Read more

Hammer Crusher,Hammer Mill Crusher

It possesses qualities of simple structure, large reduction ratio, and highefficiency. This hammer mill crusher is applicable for both dry and wet crushing. The compression strength of the materials shall not exceed 100 MPa, while the moisture content shall be lower than 15%. Working principles of hammer crusher

fundamental ne crusher

A fundamental model of a cone crusher UQ eSpace 199711 A fundamental model of a cone crusher. Abstract. A formal approach to the modelling of a cone cru

HPT Multicylinder Hydraulic Cone Crusher

Based on some design principles of traditional multicylinder hydraulic cone crushers like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, HPT Multicylinder Hydraulic Cone Crusher makes a breakthrough on its structure. After optimization, the structure improves the performance and crushing capability a lot.

crusher machine principles

structure cone crusher principles Tracked Crusher for construction waste and Tracked crusher is a stable, safe and reliable crawler type of crushing and screening machine which is excellent for recycling construction waste, asphalt, bricks, and concrete, and other demolition materials, as well as mediumhard natural ore ...

What Do You Need To Know About Cone Crusher Working Principle

Jul 01, 2014 · Jul 01, 2014 · A cone crusher is a specific type of crushing equipment, able to crush any type of mediumhard raw materials and ores. Although its design and working principle are very identical to the jaw crusher, the cone crusher provides the contractors with less owning and operating costs and is easier to adjust to a specific appliion.

grinding and cone crusher, jaw crusher, mining mill

Hydraulic Cone Crusher. Based on some design principles of traditional multicylinder hydraulic cone crushers like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, Multicylinder Hydraulic Cone Crusher makes a breakthrough on its structure.

Cone crusher, Cone crushers, Cone crusher ...

cone crusher is also called compound stone cone crusher. It's semi hydraulic and semi spring cone crusher to crush midhard and above midhard ores and rocks efficiently. crusher is popular stone crusher in aggregates production plant. ≤200mm Feed Size; 75315KW Motor Power; 20–800 t/h Processing capacity

Crushers For Sale

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be .

Granite Crusher For Sale

Granite crushing process design, SBM granite crusher for sale as the selection of laminated crushing principle device, in order to reduce the loss of wear parts. Typical laminated device configuration is two broken jaw or broken jaw plus cone crusher process configuration.

Latest Posts

- كسارة الحجر تصنيع المعدات

- مقارنة سعر كسارات مخروط

- تستخدم الكسارات المتنقلة الجزائر

- صنع في السعودية كسارات الصخور

- متر الرمل مشروع آلة محطم تقرير

- الذهب معدات تعدين الحجر المحمول

- مصدري محطة تكسير الحجر

- مخروط محطم مبدأ العمل مصر

- المستخدمة الكرة مطحنة تكلفة المعدنية

- مصنع كسارة الفك بعجلات

- بيع مصنع غسيل الذهب التعدين

- كسارة تصادمية عمودية 750 tph

- حساب تكلفة إنتاج كسارة الحجر

- خام الذهب مخروط محطم المورد في المملكة العربية السعودية

- الفك الصخور محطم المحمولة شاشة

- Conveyor Belt Rubber Cover

- Rotary Yield Calculation Formula

- Jaw Crusher Inspection

- Stone Crusher Plant Gujarat Malaysia Price

- Stonne Crushing Machine In Spain

- Cement Clinker Mill

- Chamshu Longte Grinding Ball

- Lay Hermes Head Rockman

- Clean Processing And Utilization Of Coal Energy

- Crusher And Mills Egypt

- Anka Copper Zamfara

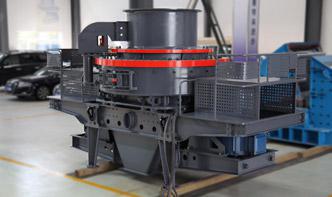

- Vsi Crusher Maldives For Sale

- Balls For Ball Mill Larger Professional Manufactures

- Mining And Beneficiation Stone Crusher

- Rock Crusher False