The Production Process Of Kaolin

production process of kaolin

Kaolin process flow which is important to kaolin processing mainly consists of the following stepscrushing, precipitating, classifying, calcining crushing process which is the first step of the process flow has impact on the quality of kaolin powder, hence customers prefer to choose vertical mill with superior performance to process kaolin.

procrss of washer kaoline production

Washed kaolin production process News FOSHAN. Washed kaolin production process Washed kaolin is produced by coarsening slurring sieving grinding centrifuging grading chemical and possibly magnetic treatment concentration and drying of coarse clay to achieve the desired purity particle size and brightness And residue The washed kaolin is an aqueous clay that retains 14 of the bound hydrated ...

How To Process Kaoline

Beneficiation Process Of Kaolinite Clay: Kaolin Processing. Kaolin is an important industrial mineral having numerous uses and requiring various market specifiions. high brightness kaolin clays represent a continuing challenge to the producer. an advancement in this field of kaolinite clay beneficiation has been a patented process developed by minerals and chemicals philipp corporation .

process of produsing kaolin

Kaolin Manufacturing Process And Plant Kaolin Production Line Price. Kaolin is a kind of common nonmetallic ore which is widely used in the production of ceramic refractory materials rubber plastics leather chemical industry »More detailed. Get Price; China Clay Product Associationkaolin. China Clay Producers Association (CCPA) is organized to advance and encourage development and production ...

Beneficiation Process of Kaolinite Clay: Kaolin Processing

· Production advantages are that the process uses conventional equipment and ordinary flotation reagents. Minerals such as calcite, fluorspar, silica, barite, sulphur, etc., are possible carriers. The Flowsheet. The first step in processing kaolin clay is to slurry it in a blunger with water and a dispersing agent. Degritting using screens ...

Processing Of Kaolin In Nigeria

· Processing kaolin. to process kaolin, there are two different types of processes involved, which are (1) wet process and (2) dry process. the wet process is basically used when impurities of the silica content in the crude or raw kaolin are on the high side. i t results in the production of highgrade kaolin mainly used in pharmaceutical. Processes Of Kaolin Mining In Nigeria. Processing of ...

Kaolin: processing, properties and appliions

KAOLIN: PROCESSING, PROPERTIES AND APPLICATIONS 89 MINERALOGY, CLASSIFICATION AND OCCURRENCES Mineralogy The term "kaolin" is also used as a group name for minerals including ka olinite, nacrite, deckite and halloysite. Many authors, however, use the term kaolinite group. With the exception of the hydrated form of halloysite, all of these minerals have essentially the same .

Kaolin: processing, properties and appliions ...

· · Wet process The wet processing of kaolin is more complex than the dry process tech nique. The water wash process scheme for kaolin coating and filler produc tion is shown in Fig. 7. The first step is simply to make the crude clay into a slurry. In order for the kaolinite to be separated from the mineral impurities such as quartz and mica and to be fractionated into fine, .

USB2

A process for producing high grade metakaolin directly from kaolinzed sands ore body. In one embodiment, a source of kaolin ore is reduced in the size to a size distribution of between −2 inches and 10 mesh. The ore is then dried in a dryer at a temperature of not greater than 180° C. to a moisture content of not greater than % by weight to liberate kaolin and calcined at a temperature ...

Utilization of kaolin processing waste for the production ...

· The kaolin processing industry generates large amounts of waste in producing countries such as Brazil. The aim of this study was to characterize kaolin processing waste and evaluate its suitability as an alternative ceramic raw material for the production of porous technical ceramic bodies. The waste material was physically and chemically ...

Optimization of the process of efficiency management of ...

of kaolin, modern industrial production is mainly focused on the use of materials with a maximum content of kaolin minerals and a minimum content of quartz, potassium feldspar, mica, minerals and oxides of iron and titanium (Sobolevskyi, R., et al., 2015). The economic efficiency of kaolin deposit de velopment is largely determined by the perfection of technological solutions and depends on ...

The Calcination of Kaolin Clay

Calcined kaolin materials are important in many products and industrial processing endeavors, as is exhibited by their growing market demand. Calcination backed by expertise is essential in controlling and reaching the desired end product characteristics of a given kaolin material. And while calcination is a relatively established thermal technique, the variability of raw kaolin materials ...

the production process of kaolin in ghana

the production process of kaolin in ghana; the production process of kaolin in ghana . Kaolin clay Britannica,Mineral Information Institute When kaolin is mixed with water in the range of 20 to 35 percent it becomes plastic ie it can be molded under pressure and the shape is retained after the pressure is removed With larger percentages of water the kaolin forms a slurry or watery suspension ...

grinding of kaolinite processing

grinding process kaolin. Quarry processing is depending on the raw mineral property and the final usage of the product. There are two technologies applied in the industry production dry process and wet process. In general the hard kaolin adopts the dry. Chat Now ; Influence of dry grinding on talc and kaolinite . After 15 min grinding the specific surface area of kaolinite drops continuously ...

the production process of kaolin

the production process of kaolin. Nov 27, 2020· The lowcost production process is unlike other industry methods. Other processing methods may use chemical bleaching and multiple wet mechanical and magnetic separation methods, said Sorensen. WA Kaolin's proprietary process has several distinct stages. Product is prized for purity, high quality and brightness . Know More. Beneficiation Process ...

METHOD FOR PROCESSING KAOLIN CLAY

I claim 1. In the wet processing of kaolin clay by steps which comprise mixing crude kaolin clay in water in the presence of a primary clay dispersant to form a deflocculated clay slurry, removing coarse particles therefrom so as to obtain a fine size fraction of clay in the form of a deflocculated suspension, flocculating said deflocculated suspension by adding an acidic substance, filtering ...

Kaoline Process Plant

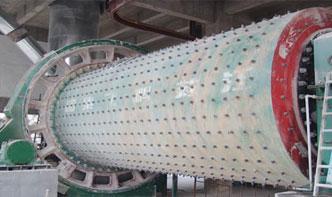

Kaolin Processing Technology Appliions . the production process features the separation of kaolin from quartz and feldspar by dry and wet plant equipment consists mainly of: mining equipment, crusher, roller with classifier, attritioning cells, .

Latest Posts

- مصنع تكسير الحجارة ultratech

- تشغيل آلة تكسير الحجر بواسطة مولدات diseal

- الرمل إنتاج باستخدام VSI محطم

- مصنع الاردن لغسيل الذهب

- السعودية الطواحين

- آلة صنع الحصى المحمولة الجزائر

- تصنيع آلة محطم في السودان

- ذروة كسارة كسارة

- طحن الحجر في اليمن

- تعدين الصخور في شمال كارولينا

- طاحونة جعل 50tph مصر 300 شبكة

- تتطلب مصنع مطحنة أعلاف الدواجن على تأجير مصر

- تعدين الرمال في السودان

- مورد مطحنة الكرة في تايلاند

- تستخدم الرمال صنع المعدات في

- Manufacturing Product Of Raymond Chhindwara

- Figure Of Latelier Concasage Ciok

- Nitrogen Hammer Crusher Mill Price In Iceland Sale

- Plans To Build A Small Por Le Rock Crusher

- Construction Waste Recycling Equipment Crushing Machines

- Mining Construction In Gaunteng

- Small O Ygen Plant For Sale In Usa Stone Quarry Plant Congo

- Beli Ball Mills Di Kenya

- Slag Crusher Machine In Mumbai Belize

- Dust Collector Ball Mill Scales Blower

- Casting Grinding Mill Ball

- Low Noise Plastic Crusher Machine

- Operation And Maintenance Manual Loesche Vertical Roller Mill

- Jaw Crusher 200 Mesh Coal In Australia

- Mobile Stamp Mill For Sale Coal Russian