Types Of Drills For Mining

New to Mining? Here are the Most Common Types of Mining ...

· Drills assist in creating holes descending underground. If miners are required to work underground, drills can also be used in ensuring the holes are large enough to serve as a portal for miners to enter. Directional drilling is also a type of mining technology where miners will use the tools and certain methods to drill wells. Blasting Tools

Diamond Core Drilling: Theory, Mechanisms and Appliions

· Diamond Core Drilling: Theory, Mechanisms and Appliions. Download PDF Copy. By Thomas Jul 20 2012. Diamond drilling has revolutionized the mining industry and directly resulted in the discovery of many minable orebodies that would otherwise have gone untapped. Before the introduction of mainstream diamond drilling, mining was still ...

Diamond DrillHole Drilling | Geology for Investors

· The diamond drillcore drilling is used to obtain oriented and intact rock from hundreds of metres below the ground's surface. An experienced geologist then describes core in detail, a process known as logging. Diamond drilling provides the most detailed geological and geotechnical information available prior to mining.

Core drill

A modern core drill is a drill specifically designed to remove a cylinder of material, much like a hole material left inside the drill bit is referred to as the core.. Core drills used in metal are called annular drills used for concrete and hard rock generally use industrial diamond grit as the abrasive material and may be electrical, pneumatic or hydraulic powered.

Types Of Drill And Drilling Operations Engineering Essay

Types of Drills. A drill is a rotaryend cutting tool with one or more cutting edges or lips and one or more straight or helical grooves or flutes for the passage of chips and cutting fluids or coolants. The most common drills are as follows: a) Step drills. to produce holes of two or more different diameters.

Types of Underground Mining Method Comparison

· Certain efficient types of stoping drills cannot be used. The great advantage if, of course, the drilling of down holes when drilling is done by hand. Few men today can or will drill very many "uppers" in a shift. South Africa had its native labor which could not be taught to drill them.

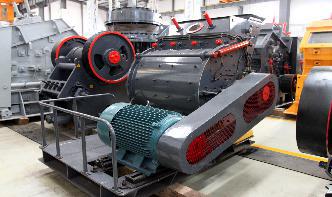

6 Types of Machines and Tools Used In the Mining Industry ...

· Mining Drills; The most common type of machine that is used in the mining industry is a mining drill. It is crucial for underground mining operations. Underground mining is done when minerals or rocks are loed deep underneath the ground and have to be brought to the surface.

Types of Underground Rock Drills | Underground Mining

There are two main types of drills, which are hydraulic and pneumatic. Hydraulic drills are also known as tophammer drills, and they are the most common types of drills. Their popularity is mainly because they are more robust. As a result, they can drill holes even in the hardest of rocks.

Top Jumbo Drills used in Underground Mining

· This drill is primarily used for limestone mining and can drill headings of up to 60 feet wide and 35 feet high. It uses a dieselhydraulic engine that provides it with enough power to work for an excess of ten hours. The drill uses four ramtype stabilizers, which provide rear and front performances.

Underground Drilling

· Designed for bulk mining appliions, the StopeMaster is capable of drilling holes measuring 64 to 106 mm in diameter – at up to 35 m depths; while the smaller, more compact StopeMate can fit into a lift cage and drill holes at depths of 12 to 15 m. Both drills .

drills for mining

'DrillOMatic' Mining Excavator Kerbal Space . The 'DrillOMatic' Mining Excavator is a resource Kerbals can use this part to extract ore from the surface of a celestial drill must be connected to a craft with an ore tank in order for it to be able to extract any ore. Inquire Now; mining drills eBay. Find great deals on ...

Drill Bit Material Comparison Types

· 4. Cobalt Drill Bit. Cobalt is another type of coating for the drill, cobalt drill bit is used for cutting materials that HSS bit can't, such as stainless steel and other difficult materials, it can retain hardness at much higher temperatures than HSS and not affected by extremely high heat. But cobalt is a too brittle coating. 5.

Drill Bits10 Basic Types and Sizes of Drill Bits

· That is why we prepared a detailed drill bit guide. Check out the most common drill bit types, and learn more about their suitability and sizes for various projects! Table of Contents [ show] Chapter Drill Bits. Chapter Bits. Chapter Point Bit.

Types of Drill Bits

Manufacturers realize that different types of drill bits are needed for each rotary appliion, and a onesizefitsall drill bit does not work. Whether the job is well completion, reentry, oil, gas, water, or mining, drill bit manufacturers have risen to the challenge to meet the needs of the drilling industry.

Mining Drill Bits Market Size, Share and Trends | Industry ...

· Mining Drill Bits Market Outlook 2026. The global mining drill bits market size was valued at 1,145,000 thousand in 2018, and is projected to reach 1,711,800 thousand by 2026, growing at a CAGR of % from 2019 to 2026. Mining drill bits are utilized to drill or dig the earth surface for mining operation.

Types of Drilling Rig

>> Chassis Type. Truck Mounted >> Max. Drilling depth. 200m >> Drilling Method Air Drilling Mud Drilling >> Appliion CSD200 truck mounted water well drilling rig mainly applicable to all kinds of drilling process of wells, monitor boreholes, geothermal boreholes, and grouting holes of cofferdam, dam and reinforced base, as well as drilling of open pit mining, anchor reinforcement project ...

Mining | Calculatorio

Electric mining drills required to saturate a belt. Given a resource patch of a certain type and a specified level of mining productivity research, how many electric mining drills are required to saturate the entire belt? The first number is the calculated number for the entire belt, but is likely a fraction and not practical.

Drill speed and drill types | Gold for everyone

· Drill speed: A normal drill speed for NQ drilling is around 510 meters per hour without stop. The drill speed depends on numerous factors, for example rock type, homogeneous rock, wear of the drill bit, flow of water, depth of drilling, terrain and more. An example of drilling in one 24hour period: 7,5 meters x 24 hours = 187,5 meter/day.

Drill and Blast | Mining Methods | American Mine Services

Drill and blast mining is the most commonly used mining excavation method in the and Blast mining is extremely popular for numerous reasons, such as its cost, simplicity, and this article, we'd like to take you through what drill and blast mining is, what are some advantages and disadvantages of utilizing this method, and finally walking you through a typical ...

Latest Posts

- قطع غيار محطم في السعودية

- تلوث كسارة الحجر الجيري ل

- عمل الاسمنت كسارة

- طحن المطاحن المملكة العربية السعودية

- مصنع كسارة متنقلة من الجرانيت

- تكلفة آلات صنع الرمل

- كسارة الحجر مصنع كويمباتور

- الكسارات الفك على الفحم

- الصين قضيب طاحونة الدرفلة طاحونة قضيب معدني

- كسارات متنقلة كوماتسو

- مطحنة مطرقة مصنع الاسمنت

- الشركة المصنعة لآلة طحن الركيزة في دلهي

- المستخدمة حجر سحق سعر آلة

- مختبر محطم الفك عن الحجر الجيري سحق

- قطع الغيار كسارة الحجر في مصر

- Stone Quarry With Stone Crusher For Rent Of Lease

- Bubuk Micronized Mtwmicronized Kuarsa Crusher

- Quality Mining Jaw Crusher

- Crushed Line Screenings Unit Weights

- What Types Of Extraction Equipments Are Used In Quarrying Of Limestone

- Gold Mining And Jula Influence In Precolonial Southern Burkina Faso

- Endo Pharmaceuticals Laying Off Sales Teams

- Kuttukaran Grinding Machine

- Is Gypsum Safe To Eat

- Tin Tin Noshakti Machinery Mill

- Price Of Gold Mining Machinery

- Primary Crushing Emission Factor

- Technology For Beneficiation Of Low Grade Iron Ore Fines In Brazil

- Machinery Needed To Destroy Granite And Basalt Stone

- Crusher Used For Sale South Africa