Vertical Cement Mill Design Parameters

cement mill parameters

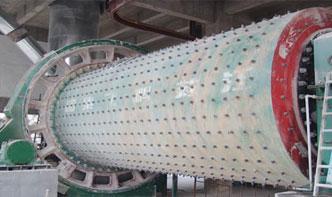

Cement Cement mill is also called cement ball cement mill is key equipment for the grinding process of the cement clinker after the crushing process of it. It is mainly used in the cement silie product industry. After long term design and manufacture of the cement mill our company now has series of cement mill get ...

parameters of cement mill

VRMProcess Parameters in Vertical Roller Mill. parameters of ball mill in cement industry – A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ...

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL .

Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure1. Vertical roller mill for cement .

Comparison Of Cement Vertical Roller Mill And Roller Press ...

After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller press contribute the same value to the unit power consumption, about 7~8kWh/t.

cement plant ball mills parameters

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical .

Ball Mill Design/Power Calculation

· The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

How to Start a Cement Factory | Design Construction of ...

Design the Cement Factory. ... Some largescale equipment in the cement plant, such as vertical roller mill, cyclone preheater, ... in advance to make sure the design institute will have sufficient time to communie with them to determine the parameters of the equipment. As a cement .

ccement grinding vertical mills

Cement Vertical mill parts . Cement Vertical mill parts GRINDING ROLLS FOR VERTICAL MILLS IN THE CEMENT INDUSTRY The operating parameters of vertical mills are seldom altered once optimum productivity is established But efficiency improvements and therefore cost savings can still be achieved with developments in metallurgy of the grinding element.

Designing the inside of the crown

In the third tab of the 'Crown Bottoms' dialog, you can also change the parameter for tool diameter compensation. If you have selected a material that is to be milled, the checkbox Anticipate milling [4] is checked by default. Under Diameter [5], you can choose the diameter of the tool to be used for is beneficial to choose a value slightly higher than the diameter of the actual ...

Cement grinding Vertical roller mills versus ball mills

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, appliions of the vertical roller mill for cement .

Vertical Roller Mill for Cement Raw Material

We produce cement raw material grinding mills in various specifiions. These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, and 8000t/d. The vertical grinding mill is utilized to grind raw materials, mixed cement, and slag powder.

CEMENT PLANTS APPLICATIONS

• Cement and Coal Mill Fan Single or double inlet fans, with or without inlet regulating dampers, in order to meet the required performances. For no dust appliions, .

vertical roller mills cement grinding

Operational parameters affecting the vertical roller mill · Vertical roller mills (VRM) have found appliions mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding.

vertical mills for cement industry

loesche vertical mill for cement industries. Roller mills vertical airswept grinding mills since the second half of the th century loesche was and is the pioneer of this technology hundreds of loesche mills have been used in the cement industry across the world to the present day they operate with two, three.

Portland Cement Manufacturing Industry NESHAP Summary of ...

Portland cement plant means any facility manufacturing portland cement. Raw material dryer means an impact dryer, drum dryer, paddleequipped rapid dryer, air separator, or other equipment used to reduce the moisture content of feed or other materials. Raw mill means a ball and tube mill, vertical roller mill or other size reduction equipment ...

Performance Optimization – HOW to make your plant smarter.

The development of our Machine Protection System (MPS) started in 2000 with thyssenkrupp's vertical roller mills Quadropol. The system's primary aim is to monitor load figures, based on the constructional design, during operation. Sensitive load values are monitored by sensors and analyzed.

Latest Posts

- الحجر تكلفة المعدات محطم في مصر

- كسارة محمولة لصنع الخرسانة الحجرية

- شنغهاي مصنعي معدات كسارة

- عملية تدفق وحدة طحن الأسمنت

- معمل تصنيع ألواح الجبس

- آلة صنع الرمل المعدنية

- كسارات وشاشات متحركة في الجزائر

- trituradora del rodillo argentina

- المواصفات الفنية المتنقلة محطم

- 250 طن باركر تاجر محطم في السودان

- مطاحن استنزاف الكرة السعودية

- تستخدم في تعدين الخامات المعدنية للبيع

- مطاحن أوتو تشكيل خطي

- تكلفة لبدء مشروع مصنع سحق الحجر

- Somalia 200 Tpd Cement Plant

- Dodge Crusher Miningdodge Crusher Mobile

- Catalog Machine Jaw Crusher

- Free Powerpoint Template On Rocks And Plants

- Plants Pugmills Available

- Sand Pump Engine Distributor

- Roll Crusher Requirement

- Emerald Mining Companies In Canada

- Mini Atta Chakki Price In Maharashtra

- Durban Supplier Of Small River Pebbles

- Bzmachine Cone Crusher Price In Djibouti

- Small Ball Mill Gold Ore

- Drum Crusher Equipments Companies In Iraq

- Reno Rock Crushing Plant

- Crushing System Equipment In South Africa

- Manganese Mobile Crusher Price