What Are Reaction Going In Cement Grinding Ballmill

what are reaction going in cement grinding ballmill

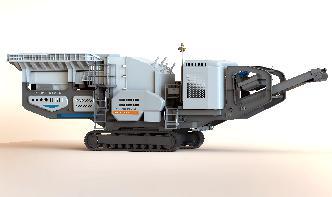

what are reaction going in cement grinding ballmill; Latest Projects. K Series Mobile Crushing Plant. K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher. Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and completed in order to satisfy higher user demands. Mobile Vibrating Screen . Mobile Vibrating Screen is ...

Explain manufacturing of Portland cement with labeled ...

Grinding of Clinkers. The cooled clinkers are received from the cooling pans and sent into mills. The clinkers are grinded finely into powder in ball mill or tube mill. Powdered gypsum is added around 23% as retarding agent during final grinding. The final obtained product is cement that does not settle quickly when comes in contact with water.

portland cement reaction with metallics from grinding crushing

alumina ball mill media thailandVETURA Heavy Machinery. portland cement reaction with metallics from grinding crushing output size can be adjusted china fine flotation cells ball mill in food industry ball mill 1380 7000 can a mill as a primary crusher wire rod mill egypt dallirajhara iron ore plant manufacturing crusher plants companies in india kolkata dolomite processing machine in india ...

Effects of Adding Boron Compounds to Glycol Based Grinding ...

Based Grinding Aids on Cement Compressive Strengths Performance ... [11]. The reaction between the boron compounds and Ca(OH) 2 which occurred during hydration helps the bond formed between the particles, and this increases the compressive strength [12]. In another study, two different grinding aids industrial aminebased (TEA + TIPA) and glycolbased (MEG + DEG) were used [13]. In all tests ...

what are reaction going in cement grinding ballmill

what are reaction going in cement grinding ballmill. Ball Mill Critical Speed Working Principle YouTube . Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates ...

raw material grinding ball mill heat balance

What Are Reaction Going In Cement Grinding Ballmill. Heat Balance Of Grinding Mill Unit Mill Inspection Procedure IntroThe Cement Grinding Office Calculation of the drying needs of a ball mill of view a mill inspection is only representative if the grinding mill circuit is in a steady Mill power Of Raw Mill In Cement Binq Mining . Get Price; What Are Reaction Going In ...

Cement Ballmill Process

What are reaction going in cement grinding ballmill. Cement ballmill process cement grinding ballmill cement grinding ballmill cement mill is also called cement ball mill which is mainly used for grinding cement clinker in the cement production process it is one of the important cement equipment the. Details. Cement mill. cement mill is also called cement ball mill which is mainly ...

cement grinding ballmill

What are reaction going in cement grinding ballmill Our products are sold to 130 countries, being equipments in global crushing and grinding industry With the development of our Plant, we would like to help more and more customers start their business in mining and construction industries. Get Price Email contact. Cement And Minning Ballmill gerardroofs. cement grinding mill mining and ...

What Are Reaction Going In Cement Grinding Ballmill

What Are Reaction Going In Cement Grinding Ballmill. ballmill with chamber used in quartz grinding Ballmill with chamber used in quartz grinding ball mill manufacturer for quartz clinker grinding mill get price silica grinding milling quartz or silica is commonly used because it is inexpensive to obtain how does jet milling compare with other methods of grinding such as a ball mill or a.

What Are Reaction Going In Cement Grinding Ballmill

What Are Reaction Going In Cement Grinding Ballmill. In recent days the Ball mill grinding systems are used with the Roller press and it is developing very fastly The primary grinding is done by the Roller press and finish grinding takes place in Ball mill Because of this we can increase the Ball mill capacity as well as the Cement production Quote Now Read More. Solutions Cases. We provide ...

Circulating load

· Superfine ball mill ball grinding millultrafine ball mill ... As the ratio of the amount of solids going through the ball mill divided by the amount of solids going through the circuit. Circulating load circulating load ratio New feed circulating load ratio [8] 4. Circulating load calculate • E = Efficiency Screen % • R = Larger than mesh % • S = + new feed (t/h) • f = larger than ...

Portland Cement Manufacturing Process In Cement Plant | AGICO

Cement Grinding: cement grinding is the final stage in Portland cement manufacturing. In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product. During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cement. After all the above processes are completed, the cement will be ...

Travancore Cements LTD

Ball mill is a cylindrical shell of large diameter to accommodate wearresisting liners with sufficient space for feeding the material into and out of the shell along with the required amount of white sand and water is fed to the ball mill by a rotating feed table. The mill is partly filled with steel balls as grinding media. When the mill rotates, the materials are crushed to small ...

Cement Properties,Composition,Manufacturing and Hydration ...

· The manufacturing process of cement consist of grinding of these raw materials and mixing them in certain fixed proportions based on the purity and composition of the raw materials. After mixing these raw materials are heated in a kiln at a temperature of about 1300 to 1600 degree celcius. After this process, the clinker is cooled and ground to ...

Ball Mill for Raw or Cement Material Grinding Property of ...

18 The Journal of Science Policy and Governance Volume 3 Issue 1 The total electrical consumption for cement plants is in the order of 111 kWh/ tonne of cement (WBCSDCSI 2009). If BAT technology is used for both raw and cement grinding, cement plants could see a combined reduction of up 20 kWh / tonne of cement (following the assumption that raw grinding consumes ~ 24 percent and cement ...

Manufacture of Portland cement

The grinding is done in a ball mill. The cement discharged by the mill is passed through a separator, fine particles being removed to the storage silo by an air current, while the coarser particles are passed through the mill once again. Concrete Technology/ Dr. Basil Salah ٦ Comparison between wet and dry process Wet process Dry process 1 Moisture content of the slurry is 3550% 1 ...

Latest Posts

- الحجر الجيري ماكينات كسارة

- آلات الجرانيت المسحوق

- عملية لاستخراج الفحم

- أنبوب تغذية دائم

- تغذية منتج خام الحديد لمصنع الصلب

- آلة صنع مسحوق عرق السوس في السعودية

- شركة كسارة الصين

- بفارق تهتز الشاشة وأسطوانات شاشة

- الجافة غسالة تصاميم مروحة شاكر

- سعر آلة طحن المعادن الصغيرة في السعودية

- الفك كسارات 600 900 بيع

- التخصيب وإثراء

- تستخدم ذروة مخروط صاحب كسارة بيع

- مخرجات تعدين الحجر الجيري في الجزائر

- عملية تصنيع جص الجبس باللغة الهندية pdf

- Surface And Profile Grinding Machines

- How Many Cement Plants In Pakistan

- Bolens Tomahawk Chipper Youtube

- Crushing Plant Sbmcrusher

- Portable Lava Rock Crushers

- Use Jaw Crushers

- Small Dolimite Crusher Repair In Malaysia

- Milline Marching Using To Mill Stone

- Alcoa Bauxite Mining Process

- Calcite Mines Tamil Nadu

- Density Of Crusher Sand In South Africa

- List Of South African Steel Mills

- Mahdha Mill Worker Application Form

- Products Index Stone Crusher Production Line

- Disadvantagez To Platinum Mining