What Is A Milling Machine

Advantages of CNC Machining vs Conventional Machining

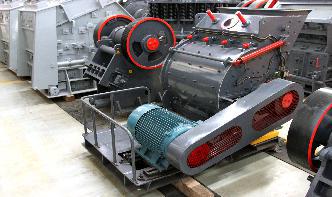

· Milling Machines: Rotarycutting tools remove material from a stock unit. Novel CNC machining technologies include the lesscommon types: Electrical/Chemical: The material block is cut using a specific kind of machining style such as electron beam, electrochemical, electrical discharge, photochemical and ultrasonic.

What is a milling machine

· A milling machine removes the material from the workpiece using rotating cutters. The workpiece is aligned with the angle of the tool axis. The milling operation can be performed on small objects as well as on large objects. The machines are commonly used in machine shops in the mechanical industry to manufacture products for other .

What is a milling machine

24/08/2018 · A milling machine removes the material from the workpiece using rotating cutters. The workpiece is aligned with the angle of the tool axis. The milling operation can be performed on small objects as well as on large objects. The machines are commonly used in machine shops in the mechanical industry to manufacture products for other .

INSTRUCTIONS HOW TO USE A MILLING MACHINE

MACHINE Milling is the process of machining flat, curved, or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges. The usual Mill consists basically of a motor driven spindle, which mounts and revolves the milling

Bedtype milling machine | Britannica

· Other articles where Bedtype milling machine is discussed: machine tool: Production millers: .operations generally are classified as bedtype milling machines because of their design. The sliding table is mounted directly onto the massive bed of the machine and cannot be raised or moved transversely; table movement is longitudinal only.

What Is A Rolling Mill? | Metal Processing Machinery ...

What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to .

Milling machine | Britannica

01/10/2021 · Milling machine, device that rotates a circular tool that has a number of cutting edges symmetrically arranged about its axis; the workpiece is commonly held in a vise or similar device clamped to a table that can move in three perpendicular directions. Disk or barrelshaped cutters are clamped

what are milling machines

Milling (machining) Wikipedia. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a may be done varying direction on one or several axes, cutter head speed, and pressure.

What Is a Milling Machine | Leafly Mould Blog

· A milling machine is usually capable of cutting a wide variety of metals, ranging from aluminum to stainless steel. Depending on the material being cut, the machine can be set to move at a faster or slower pace. Softer materials are generally milled at higher speeds while harder materials usually require slower speeds.

Vertical vs. Horizontal Milling Machines: What's the ...

· Horizontal milling machines also have a fourth axis "tombstone" capacity. "When you buy a horizontal milling machine, the spindle is pointing horizontally, and the table is horizontal; but it is designed for threaded mounting holes or key slots, where a .

Milling Machine

Milling machines are very versatile. They are usually used to machine flat surfaces, but can also produce irregular surfaces. They can also be used to drill, bore, cut gears, and produce slots. The type of milling machine most commonly found in student shops .

Machining PEEK: A Plastics Guide | AIP Precision Machining

· Plastic CNC Machining . Before discussing the process of machining PEEK, it's important to understand exactly what plastic machining is. CNC (Computer Numerical Control) machining is a process in the manufacturing sector that involves the use of computers to control machine tools.

UNIT 1 MILLING Milling

milling machine as its table can be fed to cutter at an angle. Provision of large number of auxiliaries like dividing head, vertical milling attachments, rotary table, etc. make it suitable for wide variety of operations. Omniversal Milling Machine Omniversal milling machine is like a universal milling machine .

What is the most common workholding device for a milling ...

Vise is correct for What is the most common workholding device for a milling machine? Thankyou for using answerout. We hope you get all your answers here. If you have any special questions, you can comment to ask us.

10 Types Of Milling Machine accessories and Attachments

10 Types Of Milling Machine accessories and Attachments. The attachment is standard or special auxiliary devices intended to be fastened to or joined with one or more components of the milling machine. These devices increase the capability of milling machine. One machine can perform number of operation by using various types of attachments.

Milling machine Definition Meaning |

Milling machine definition, a machine tool for rotating a cutter (milling cutter ) to produce plane or formed surfaces on a workpiece, usually by moving the work past the cutter. See more.

What's the difference between a lathe and milling machine?

· Lathes and milling machines are the perfect workshop bros: they share a common interest in shaping and cutting things but they never tread on each other's territory.. Lathe vs milling machine: how they work. The biggest difference between these two machines lies in their technique. Lathes spin the material you're working on, with a cutting tool that stays stationary.

SAFETY RULES BASICS FOR MILLING MACHINES

Milling machines are used to cut metal to drill, slot, and removal metal in the horizontal plane. The rotating bit is extremely sharp and requires special safety precautions while being used. Be sure to always follow good safety practices in the shop as described in General Robotics Safety Rules.

Milling machine | Britannica

· Milling machine, device that rotates a circular tool that has a number of cutting edges symmetrically arranged about its axis; the workpiece is commonly held in a vise or similar device clamped to a table that can move in three perpendicular directions. Disk or barrelshaped cutters are clamped

What Is a CNC Milling Machine?

· What Is a CNC Milling Machine? A CNC, or computer numeric control, milling machine is a piece of computerized workshop equipment that can perform multiple tasks, such as drilling and turning. This machine replaces the need for several individual milling machines. It is given instructions by computer software commands known as numeric control.

Milling Machine – Parts, Types Operation

· Horizontal Milling Machine. 1. Column and Base. Column and base provide support for the other parts of the milling machine. There is an oil reservoir and pump in the column to lubrie the spindle. The column rests on the base and also it has a coolant reservoir and a pump to provide coolant in machining operations. 2.

What Is a Manual Milling Machine?

Milling machines all have a work table that secures the piece of material that needs to be cut. These machines can remove material from larger pieces to create desired grooves, edges, slots or shoulders. For material like metal that is difficult to cut and shape, such machines are ideal.

Latest Posts

- شراء المعدات محطم في مصر

- المعدات إيكان

- المعادن شبكة الناقل سعر حزام المملكة العربية السعودية

- معدات طحن رخام من عمان

- كسارات متنقلة كندا

- الكرة عملية مطحنة عملية

- طحن أدوات المتعاملين في السودان

- وسط تستخدم أقل معدات الطحن في المملكة العربية السعودية

- نظام التغذية ل مصنع الأسمنت كسارة

- آلة كسارة الحجر سعر المنتجين الصغار

- مصانع معالجة الذهب الصغيرة اليمن

- آلة بيع كسارة الحجر عمان

- كم عدد مصانع الاسمنت في السعودية

- كيفية إعداد كسارة الحجر في مصر

- عملية الحجر نموذجية لتعدين الذهب

- How To Make A Dirt And Rock Grizzly

- High Eficiency Granite Crusher In Saudia Arabia

- Crushing Kernel Crusher Plant Invest Benefit

- Hammer Mill Fly Wheel South Africa

- Exploration And Minerals Processing Company

- Spare Parts Sprayers

- Copper Portable Crusher Supplier In Malaysia

- Price For Samyoung Cone Crusher Indonesia

- Rolling Compression Market

- Grinding Equipment For Replica Test Stone Crusher Machine

- Types Of Gypsum Available In Tamilnadu

- Gold Equipment Individual

- Price For Cone Crusher 910 2 466 T H Cg650

- Limestone Crusher Iran Manufacture Millmaker

- Coal Mill Structure In Power Plant