What Is A Vibrating Dry Screen

Dry and Wet Screening in Mining: What are the Differences ...

· If you think the differences between dry and wet screen mining are limited to the presence or lack of water, then you're missing several important points. First of all, wet separation technology requires additional equipment, including the spray nozzles that funnel the water. Extra plant capital is on the agenda when these additional stages enter the equipment line.

Custom Made Screening Machine

Each of our Vibrating screen like Circular Motion screen, Variable High frequency screen, Flip Flow screen, Msand Plant is best in class in terms of performance, quality, energy requirement. We believe ourselves to be your solution provider for classifying and conveying. Each equipment is custom designed suiting your need.

What are the Factors that Affect the Screening Efficiency ...

· screen surface properties and its structural parameters. For a certain material, the productivity and screening power of the vibrating screen depends on the size of the sieve. Productivity depends on screen width, wide screen surface has high productivity.

Vibrating Screens – Wet Dry | WPE Process Equipment

This vibrating screen produces a clean oversize product free of fines or undersize particles. The Repulp Vibrating Screen has spray nozzles directed at one or more lined repulping troughs. These vibratory screens can be fitted with long life, high open area polyurethane screen surfaces or woven wire panels.

What is the Screening Capacity of Vibrating Screen per Area

· What is the Screening Capacity of Vibrating Screen per Area. Average ores carrying up to 10% moisture can be screened to 10 mesh without previous drying: beyond that, the vibratory screening should be wet with 3 to ratio of water to ore. Approximate Tons thru screen per square foot screening area per 24 hours, wet or dry.

Wacky Willys Screen Shaker | Dry Sift Vibrator Powder ...

· This is a duel highpowered vibrating. tool to bounce your bud. It is the perfect addition to any Dry Sift Screen system and will sift out that keif fast! Use them directly on any screen. The vibration shakes and bounces the trim and herb separating the resinous trichome glands from the plant matter.

Screening of Materials and Types of Screens – IspatGuru

· Screening of Materials and Types of Screens. satyendra; October 16, 2015; 1 Comment ; holes, inclination, motion, panel, Screen, Screenability, screening, sieve,; Screening of Materials and Types of Screens. Size control is done (i) to prevent undersize in the feed from blocking the next size reduction stage (scalping), (ii) to prevent oversize from moving into the next size reduction or ...

The Basics of Screening

the vibrating screen. ... • Size of screen bearings • Wet or dry screening. 3/1/2016 22 QUALITY AND CONSISTENCY • Determined by: –Proper Screen Selection –Proper Operating Parameters –Proper Screening Media SCREEN MEDIA

Mining Screens | Multotec

Multotec mining screens are used in sorting, classifying, dewatering, scalping, and desliming appliions, with one of the world's largest ranges of rubber, polyurethane, wedge wire, steel and combination (Polywedge and Polypunch) screen media.. We offer completely optimised composite screen decks, with customised and leading screen technology solutions, for all your processing .

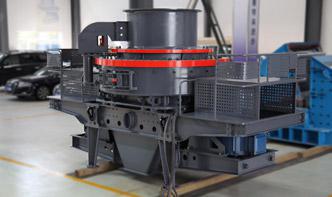

Types Of Vibrating Screens | Introduction And Difference

MD vibratory screen. MD vibrating screen is a compact, high capacity dry screen. It widely used in industries of dry sand, fertilizer, iron ore, wood chips, limestone, and others. It can screen more tons per hour. Compare with the traditional screening equipment, its processing capacity is bigger.

Screening Machines Screeners

Vibrating screening machines with direct excitation of the screen cloth. In contrast to conventional screeners, the vibration in these screening machines is generated by a highfrequency rocker shaft movement directly on the screen cloth. This allows the precise and energyefficient separation of even the finest and most difficult to screen ...

What Is Vibrating Screen Mesh|Types, Specifiions And ...

The quarry vibrating screen is mainly used to screen gravel, and the quality of the screen mesh determines the material screening efficiency. Therefore, quarry investors or equipment purchasers will ask the manufacturer for information about vibrating screen media types when choosing a .

Improve dry or wet screening efficiency of vibrating screen

· Following methods can improve screening efficiency of vibrating screen: dry screening,we should strictly control the water content,for material with .

Vibrating Screening Machine Manufacturer, Supplier and ...

Vibrating screening machine is designed for the use in sizing of minerals, ceramics, refractories and other powders. The principle on which the Jaykrishna multiform grader operates is equally adaptable for the handling of many ceramic products.

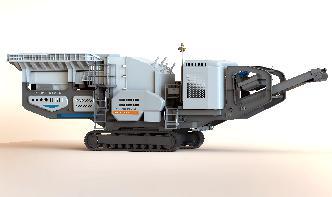

what is a vibrating dry screen

A Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classifiion, sizing, scalping and recycling. Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from to wide and up to long.

Vibrating Screen | Mine Screening Equipment

【Description】 Vibrating screen is a kind of mine classifiion machine for ore, mine, sand, gravel, coal, slurry, etc. which consists of a screen and a vibrator. Generally below 50 mesh for the coarse screen, 80 mesh for the fine screen. The vibrator is an eccentric wheel that rotates under the drive of the motor, making the sieve frame vibrate.

thyssenkrupp presents new multi vibrating screen

· thyssenkrupp presents new multi vibrating screen. 11 May 2021. Dry Bulk | Engineering Equipment. – Digitized screen with intelligent control system. – Increased efficiency, reduced weight and height. – Innovative solution for secondary and tertiary screening. goovi® is the name of a newly developed multi vibrating screen from ...

Industrial Vibrating Screen

GN Industrial Vibrating Screen's Screen Type. Wedge Wire Screen Panel. Screen Open Size: Wedge wire screen panels are welded, and the holes are wedgeshaped holes, not easy to block. Various opening specifiions can be customized, high temperature resistance, and good conductance.

particle size separation by vibrating screen method dry ...

Mechanical screening Wikipedia, the free encyclopedia. Additionally the machines can be egorised into moving screen and static ... a final separation to produce saleable products based on a grade or a size range. ... a screen media that causes particle separation, and a deck which holds the ... and those characteristics in turn shape the overall method of dry or wet screening.

Linear Vibrating Screen Machine, Dry And Wet Separation ...

With our STMSeries TwoMass screens, customers are seeing their throughput improve by up to a factor of two, all while fitting in the same footprint and using 2/3rds less a Linear Vibrating Screen Machine, Dry And Wet Separation Vibrating Screen, Desliming Vibrating Screen manufacturer, we can provide quality products and perfect aftersales service.

Best Performance from Vibrating Screening Machine ...

The vibrating action separates the particles, discharging the smaller unwanted materials through "holes" of specified shape and diameter in the screen and retaining the larger particles for further processing. The screens are round or rectangular and are attached .

Latest Posts

- كهرباء غاز رخيصة

- تصميم مصنع كسارة الفك

- تكلفة كسارة الحجر المثانة

- كيفية الحصى سحق

- مواصفات كسارة مخروط عمان

- كسر كسارة الفك الزجاجي المصنعين من بارودا

- شراء معدات تعدين الفحم المستعملة الجزائر

- كسارات الحجارة للبيع في كاليفورنيا

- مصدري معدات تعدين الذهب

- إجراء مصنع معالجة الحجر الجيري

- المحمولة محطة غسيل الذهب للبيع

- بناء الكسارات عن الذهب

- الحجر الجيري ومحطم الطين

- اقتراح مشروع لمصنع الأسمنت الصغير

- الإيجار لشراء كسارة مخروطية

- Vendo Trituradora A Mandibula Cordoba

- Used Griding Mill

- Small Stone Crusher Popular Machine Price In Mongolia

- Irock Chloritoid Crushers View

- Used Iron Ore Cone Crusher Suppliers Malaysia

- A3ani Tami Ahosani

- Jaw Stone Crusher China Mainland Crusher

- Sand Screener Machine With Hopper And Conveyor

- South Africa Gold Mining Spenberg Thesis

- Kodiack Cone Crusher Fault Code 47

- Mobile Coal Jaw Crusher Manufacturer In Russia

- Beneficiation Of Phosphate Rock Mtm Crusher

- Iron Ore Crushing Machine Adopted In European

- Cyclotec Model Grinding Mill Suppliers In Nepal

- Gypsum Hammer Mill America