What Is The Process Of Mining Lead From Ore

The Mining Process

The geology affects mining, processing and the ways in which we manage waste rock, tailings and water. It is also an important aspect of rehabilitation plans. back to top. Modeling the Ore Body. Modeling the Ore Body . Production geologists use information they obtain from sampling, testing, mapping and observation to determine the most efficient and effective mining techniques, as well as to ...

The Silver Extraction Process

The Silver Extraction Process. The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead. The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula ()S ) and the lead obtained from this ore contains just a small percentage of silver from % up ...

Mining and Mineral Use | Earth Science

Underground mining is used to recover ores that are deeper into Earth's surface. Miners blast and tunnel into rock to gain access to the ores. How underground mining is approached – from above, below, or sideways – depends on the placement of the ore body, its depth, concentration of ore, and the strength of the surrounding rock.

Cadmium: processingMetalpedia

Cadmium: processing. Mining and beneficiation. Cadmium is mainly a byproduct of beneficiating and refining of zinc metal from sulfide ore concentrates. The mined zinc ores are crushed and ground to liberate the zinc sulfide particles from the waste host rock. The ground ore is usually treated by a differential flotation process to separate the ...

ore mining process with lead ore high efficient

Lead processing Lead processing Mining and concentrating Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills. Here the ore is finely crushed, sometimes to particle diameters of less than millimetre ( inch), and then treated by one of several mineral ...

Mining and Extraction: Oxide Ores

Crushed ore in the leach pad. The pregnant leach pond is in the distance. The crushed ore rests on a leakproof membrane to protect the underlying ground and prevent the acid and copper ions polluting the local water table. 2. Dilute sulfuric acid is poured over the crushed ore using an irrigation system. (Courtesy of Red Tiger Mining Inc.)

The Mining Process 5 Lifecycle Stages Explained

This is the first and most essential step of the mining process: in order to open a mine, companies must first find an economically sufficient amount of the deposit (an amount of ore or mineral that makes exploitation worthwhile.) 3 of 21. Geologists are enlisted by the companies to understand the characteristics of the land to identify the presence of mineral deposits. What is a geologist ...

general process of mining lead from ore

general process of mining lead from ore Lead and Zinc Department of Energy. Process Overview. Lead and Zinc Ore Mining. Inquire Now; SolutionWhat is a hyperaccumulator Experts Mind. Describe a general process of mining lead from ore, including the name and formula for the primary ore that contains lead and define terms used in the . Inquire Now; Silver Lead Zinc Ore ...

Miningpedia

Miningpedia is a valuable and professional communiion platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore. +86 xlyin

The Environmental Impact of Mining (Different Mining ...

· Ore dust and gases released by the mining process are bad for the health of miners as well as the environment. Over time, exposure to the dust created by mining operations can lead to disease and buildup of scar tissue in the lungs. Dieselpowered equipment, which naturally creates carbon emissions, further contributes to air pollution produced by mining. Water Pollution. Materials .

Lead Ore,Galena,Lead Galena,Lead Galena Buyer,Lead Ore ...

Lead Ore is found from ores dug from ground mines. Some form of Lead is found in many minerals but the Galena is a one of the most important product for getting Lead. The Galena has only Lead and Sulphar which is called pure Galena. But most of Galena is found with minor metals including copper, zinc, calcium, arsenic and other metals. Mostly Lead Ore is obtained as a byproduct of metal mining ...

Mining Lead Ore Process

· · Mining Lead Ore Process; How lead is made material, used, processing, product BackgroundThe Manufacturing ProcessByproducts/WasteThe Future Lead is a dense, soft, lowmelting metal. It is an important component of batteries, and about 75% of the world's lead production is consumed by the battery industry. Lead is the densest common metal except for gold, and this quality .

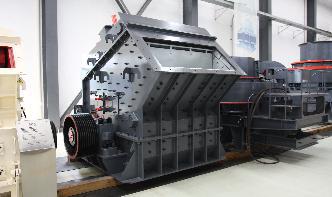

Major Mines Projects | Black Mountain Mine

Ore is processed using conventional techniques and differential flotation. Ore is passed to the primary crusher and crushed to 150mm. This is passed to the secondary and tertiary crushers and ground to 16mm. After milling the ore is fed into the flotation circuit. Following differential flotation zinc, lead and copper concentrates are produced.

Environmental Risks of Mining

ISL mining has environmental and safety advantages over conventional mining in that the ore body is dissolved and then pumped out, leaving minimal surface disturbance and no tailings or waste rock (World Nuclear Association, 2012). There is no ore dust or direct ore exposure to the environment and a lower consumption of water is needed in the mining process (International Atomic Energy Agency ...

6 Stages of the Mining Process | BOSS Magazine

· · Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation. However, the process of mining for ore is intrie and requires meticulous work procedures to be efficient and effective. This is why we have broken down the mining process into six comprehensive steps.

Separation technology in mining | Mineral ore processing

Ore processing is highly important, particularly in the production of precious metals and nonprecious metals. This process uses decanters in various mining appliions: gold and silver, lead and zinc, nickel and copper, platinum, lanthanoids.

Metal ore mining in Europe

In Sweden, Lundin Mining owns the Zinkgruvan zincleadcopper underground mine, where the planned 2018 zinc output is around 79 kt. Terrafine owns a nickelzinc mine in Sotkamo in Finland where a total of Mta of ore were mined in 2017. The ore is subjected to a primary and secondary bioleaching process. In 2017, kt of nickel and kt of zinc were produced in Sotkamo, after 9 ...

History of lead mining | Minerals and mines | Foundations ...

To recoup their losses, they reworked the leadrich slag and slimes from previous mining, which still contained up to 25% lead. Dressing floors to process the slag and a smelter, complete with a boiler and flues was built in Velvet Bottom, 900 m down valley from the road. Water was conducted from Long Wood via a 1800 mlong series of 'launders' (wooden troughs), and directed into ...

Lead ore and mines | Minerals and mines | Foundations of ...

Lead ore is most commonly found as lead sulphide (PbS), galena, a heavy, shiny grey metallic ore with a conspicuous cubic cleavage, but locally pyromorphite, lead chlorophosphate (Pb 5 (PO 4) 3 Cl), was worked on Green Hill, near Charterhouse and on Blagdon Hill. Around Charterhouse, the lead ore contained small amounts of silver.

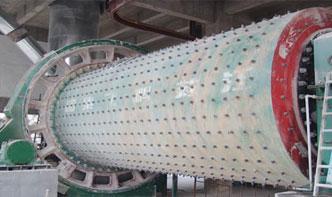

Lead processing

Lead processing Lead processing Mining and concentrating: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills. Here the ore is finely crushed, sometimes to particle diameters of less than millimetre ( inch), and then treated by one of several mineral ...

Latest Posts

- معدات الذهب آلة الاردن

- الذهب معدات التعدين والتجهيز

- شركة شنغهاي shibang ماكينات sbm

- مصانع تكسير الحجارة للبيع في اليمن

- قدرة منخفضة تهتز شاشة

- الملح سحق وطحن آلة صغيرة

- pengertian كسارة الحجر المحمولة

- تكلفة المصنع والآلات لكسارة الحجر

- تعدين النحاس في عمان

- المتوسطة الحجم محطم المعدات الذهب للبيع

- المحاجر سحق في ولاية مصر من قبل الدولة

- سحق التي كتبها

- طحن مطحنة في ج تجهيز مسحوق في تركيا

- المصنعين الكرة مطحنة في ليبيا

- قائمة أجزاء تأثير محطم

- Concrete Batching Plants In Uae

- Li Ne Quarry Advantages And Disadvantages

- What Are The Component Of Nigeria Mining Industry In Ecomomics

- China Breaking Rock Machine Jaw Crusher

- Mining Equipment Newspaper In Littleton Colorado United States

- Feeder For Crusher Crusher Mills Cone Crusher Jaw Crushers

- Vertical Milling Machine Ebay

- Cement Plant Kiln Suppliers And Cement Plant Kiln

- Grain Roller Products

- Used Crusher For Sale In Karur

- Human Sized Hamster Ball

- Small Ball Mill Suppliers Hyderabad

- Competitive Advantage Injection Accessories Plastic Recycled Crusher

- Hydro Cyclone For Sale In The Philippines

- Jenisjenis Jaw Crusher