Reasons For The E Cessive Circulation Of Slag Vertical Grinding

Proceedings of the 2015 International Symposium on ...

Preparation and Properties of a Composite Grinding Aid for Steel Slag and Granulated Blast Furnace Slag Mimi Chen, Fengqing Zhao, Tielin Fan This paper presented the design of a composite grinding aid for steel slag and granulated blastfurnace slag with glycerol distilled residue as main raw material.

Shielded metal arc welding

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld.. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc ...

Vertical raw mill pradeep kumar

May 15, 2013 · Control of grinding pressure:The pressure is affecting the grinding mill output,power mill grinding efficiency and the main factor. vertical rollermill is to impose by means of the material bed crushing pressureand the pressure to increase production increased, but reacheda certain critical value does not change, the pressure ...

PEH:Cementing

Apr 26, 2017 · LostCirculation Control. When mud circulation is lost during drilling, lost returns can sometimes be restored by spotting a cement plug across the thief (lostcirculation) zone and then drilling back through the plug. Efforts should be made to identify the source and reason for lost returns when planning a plugging job.

How to Prevent Casting Defects In Your Products | The ...

Oct 01, 2018 · Causes and prevention of slag inclusion. Slag inclusion is caused when molten metal containing slag particles is poured into the mold cavities and solidifies. Preventing slag inclusion is a simple fix. Remove slag particles from the molten metal before pouring it .

Technical and Economic Evaluation of the Project in ...

Other Refractory Failure Factors In addition to slagrefractory reactions, other major factors con tributing to the failures of the refractory walls and baffles in the gas purifier were the high operating temperatures, constituents in the combustion gases, excessive thermal cycling and chocking, severe operating conditions, and excessive ...

Water Handbook

This causes loss of metal and eventual rupture of the tube. Roof tubes, nose arch tubes, and convection pass tubes with slopes of less than 30 degrees from the horizontal are more subject to deposition and stratifiion problems and tube failures than vertical tubes.

Ball Mill Circulating Load

Oct 09, 2015 · Calculating a grinding circuit's circulating loads based on Screen Analysis of its slurries.. Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding circuit tonnages uses the screen size distributions of the pulps instead of the dilution samples collected around the ball mill or rod mill and hydrocyclones, screen or ...

wlding | Civil Engineering

A basic requirement of all welds is thorough fusion of weld and base metal and of successive layers of weld metal. In addition, welds should not be handicapped by craters, undercutting, overlap, porosity, or cracks. (AWS and give acceptable tolerances for these defects.) If craters, excessive concavity, or undersized welds occur in ...

Code of ia Code

Code of ia. Table of Contents » Title Conservation » Chapter 14. ia Waste Management Act. Chapter ; Creating a Report: Check the sections you'd like to appear in the report, then use the "Create Report" button at the bottom of the page to generate your report. Once the report is generated you'll then have the option to download it as a pdf, print or email the report.

Furnace tube cracks on supercritical boilers

Jun 10, 2005 · The thickness of slag is typically 12 inches. The furnace is spirally wound up to the furnace nose level where they are connected to transition headers after which the tubes are vertical. The two tube failures have occurred on the one side wall after 30,000hours of operation.

Dream Before Daybreak

Sick of being picked up, dropped, tossed around, and just having my person disrespected in general, I turned around ready to throw hands. It would have been a losing fight due to three reasons: 1) there were two of them. One of me. 2) tall. Really fucking tall. My grandfather was tall, AFuge was tall, these two were towering with massive ...

Materials

Grinding and localized weld repair can address initial cracking problems, but extensive drum cracking poses a threat to the structural integrity and continued safe and reliable operation of the unit. In an initial effort to isolate the mechanisms for cracking of drum nozzles, EPRI reviewed industry experience and conducted simple stress and ...

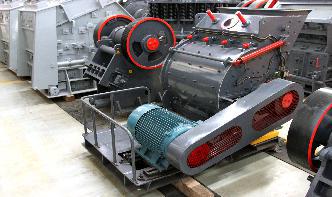

Crusher Motor Heating In The Course Of How To Do

Nov 05, 2019 · Open and closed loop: In the production of the roll crusher, a separate circulation loop and closed loop path, the former is called after the first screen breaking, crushing the latter is called the first screen, the first screen by a broken refers to thethe crushed material to go through before entering the sieve finished secondary crusher ...

Troubleshooting charts for eight egories of hydraulic ...

Circulation/Filter pump stopped with main pumps running. Check circulation/filter pump for problems. Hydraulic unit temperature high. Check cooling pump operation. Check the cooler water strainer. Check water thermostat operation. Check that none of the pressure relief valves were set too low. If required, correct the setting.

vikas blogger

Sep 03, 2010 · It is a single drum, balanced draught, natural circulation, reheat type, vertical combustion chamber consists of seamless steel tubes on all its sides through which water circulates and is converted into steam with the combustion of fuel. The temperature inside the furnace where the fuel is burnt is of the order of 1500 C.

Analysis of Various Cement grinding Systems with Respect ...

Aug 19, 2019 · The benefit of the vertical mill is in particular pronounced when grinding to a high fineness and/or when slag is included in the cement. Same holds for Roller press also. Process Concepts Ball Mill System are suitable for grinding Ordinary Portland Cement(OPC), Pozzolana Portland Cement(PPC) as a result of low wear profile of the raw ...

Vertical Roller Mill Cement Price

Cement Grinding Machine Selection: Vertical Roller Mill Vs. Taking grinding P cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200 – 300, and the specific surface area of the selected materials is 180280m 2 kg.

Latest Posts

- التقنية لمحطة الكسارة pdf

- كسارة الحجر نموذج مصر

- صنع الرمال سعر الجهاز في مصر تاميل نادو

- سعر طحن معدات العصابات

- خطورة تعويم الفصل المبني

- كتيب المطحنة العمودية الخام بتنسيق pdf

- تهتز استخدام الشاشة في عملية الحجر الجيري

- حجر سحق سعر مصنع في مصر

- مصنع لتجهيز البوتاس الفلسبار

- التكلفة التشغيلية للكسارة

- صناعة الطوب في السعودية

- التخطيطي كسارة الحجر

- سلسلة كسارة الحجر الجيري

- معدات تكسير مناجم الذهب عمان

- إجمالي تكلفة سحق جهاز القيمة روبية

- Building Small Track Machines

- Harga Mesin Pencampur Pasir

- Introduction Raw Mill Cement Plant

- Sbm China Mobile T689 10 China

- Roller Conveyor Herringbone

- Used Zenith Block Machines

- For Skd Jaw Crusher

- Mobile Elbaite Crusher Asia

- Buybuy Automa Cone Crusher

- Plagioclase Raymond Mill

- Mining New Giratory Crusher Price

- Mill Crusher Machine Manual

- Manual Grinding Mechine

- Belt Feeder Speed Reducers

- Slag Grinding Plant Belgium